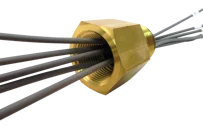

To design safe, electrical systems for hazardous locations, pay close attention to each and every electrical component that you use – including wire bushings. It may be easy to overlook explosion-proof wire bushings or conduit sealing hubs since they’re typically just one, seemingly minor part of a more complex electrical system. Yet, these components actually play an outsized safety role in hazardous areas. Applications ranging from liquid natural gas (LNG) handling to factories with combustible dust all have a need to prevent leaks around wires that pass through pressure walls, ensuring safety and compliance with agency requirements.

Customizing Feedthroughs and Wire Bushings for UL Compliance

In the past, it was difficult to find feedthroughs and wire or line bushings that you could customize to your needs while meeting UL and other compliance standards for hazardous locations. However, there’s now an approach to feedthrough and wire bushing design that makes it far easier to meet all the relevant regulations without sacrificing design freedom. The key to this approach involves the use of epoxies to create hermetic seals around the wires.

Wire bushings and feedthroughs can be designed in different ways including the following categories:

- Sealed wire feedthroughs – protecting against the penetration of liquids and gases

- Hermetic wire feedthroughs – hermetically sealed under pressure and vacuum

- Submersible wire feedthroughs – available for submersion in liquids and gases, from cryogenic liquids to fuels

- Conduit seals – simple, rated fittings with wire or connector ends to simplify the installation of a hazardous area approved electrical connection

Learn more about:

- UL Listed epoxy seals and their physical properties and compatibility

- Benefits of hermetically sealing wire feedthrough

- Meeting international hazardous area standards with wire bushing seal designs