Hazardous Locations / Oil & Gas

Serving hazardous-area approved hermetic electrical solutions

to the Oil & Gas Industry.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

At Douglas Electrical Components, we provide explosion proof electrical fittings such as electrical feedthroughs, explosion proof wire seals, and wire bushings for hazardous locations in custom and standard packages. We understand the critical role these explosion-proof electrical fittings play in ensuring the safety of operations. Our products include fully packaged and cured epoxy designed for both hermetic vacuum and positive pressure environments. All our explosion proof seals are engineered to prevent the risk of electric equipment sparking that may cause catastrophic incidents in hazardous areas. We help customers to improve their legacy designs featuring cement-based seals that are prone to cracking and failure over time with durable and resilient explosion-proof seals.

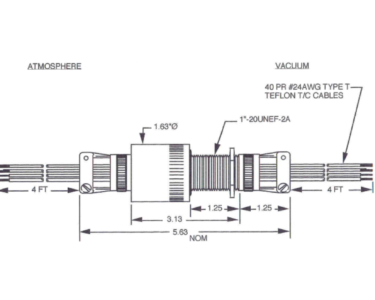

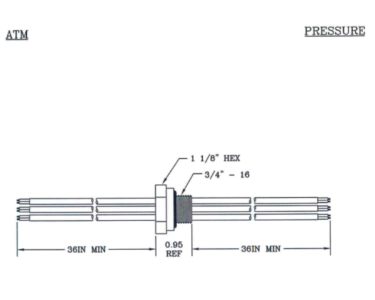

Our design capabilities allow us to offer both the mechanical hermetic seal against the explosive atmosphere and reliable process sealing in applications that experience pressurized environments, such as compressors, cryogenics, hydraulics, pumps, level transmitters, and instrumentation.

Our hermetic feedthroughs are designed for various temperature and pressure environments. For example, Douglas can fabricate custom designed explosion proof feedthroughs for LNG storage and transportation systems.

Custom Explosion Proof Electrical Seals for Hazardous Locations

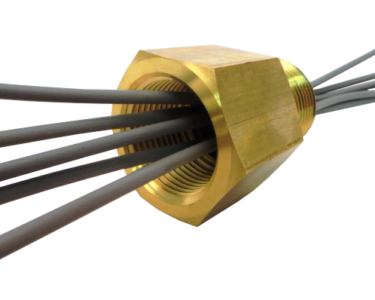

We partner with our customers to develop, design, and approve custom explosion proof seals for hazardous locations. We employ epoxy technology to create high-density explosion proof feedthroughs in compact mechanical packages. We take into account the conditions of your hazardous location to ensure the safety of these electrical connections. We can customize these explosion proof conduit seals in terms of wires, cables, connectors, circuit boards, fiber, or some combination thereof.

Partnering with Douglas Electrical Components for your custom explosion proof seals means ensuring compliance with industry standards on safety and performance. Our hermetic seals for hazardous locations comprise radial O-rings, threaded connections, ANSI/ASME flanges, direct cast into customer housings, and custom machined parts. We use epoxy resins for creating explosion proof seals for our connectors that are made from stainless steel and specialty alloys.

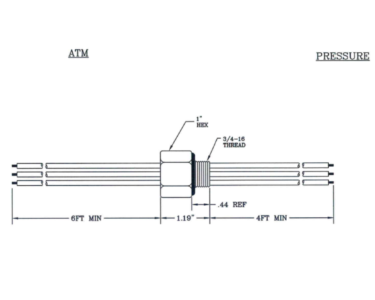

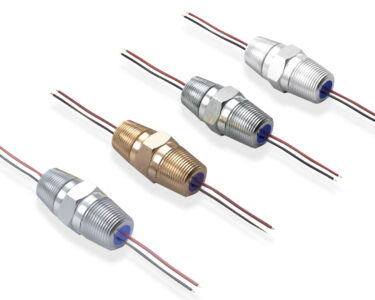

UL1203 / ATEX / IECEx Exd Standard Explosion Proof Wire Bushings

Douglas Electrical Components offers the standard UL1203 Class I Division 1 explosion-proof wire bushings for use in hazardous locations. ATEX Exd Flame-proof line bushings can be designed using our 57754 series. This type of sealing allows customers to save time and effort on the field by hermetically sealing electrical connections for transducers, transmitters, and instrumentation through the conduit. With the epoxy already sealed within the fitting, installers save time and effort by dropping in a wire bushing to meet the safety requirements.

Customers can select the wire type, gauge, color, and length on both ends of the explosion proof wire bushing. Our team can help meet the wire density parameters based on the selected options.

Haz Loc Solutions

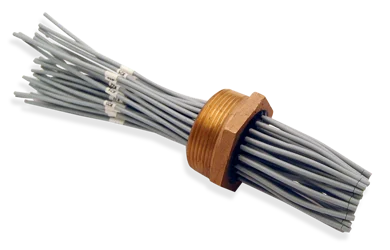

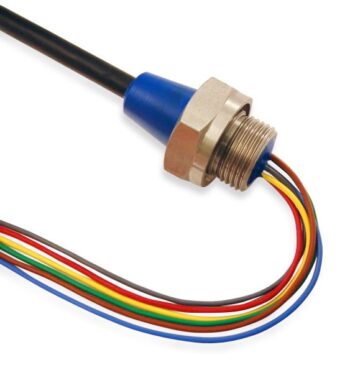

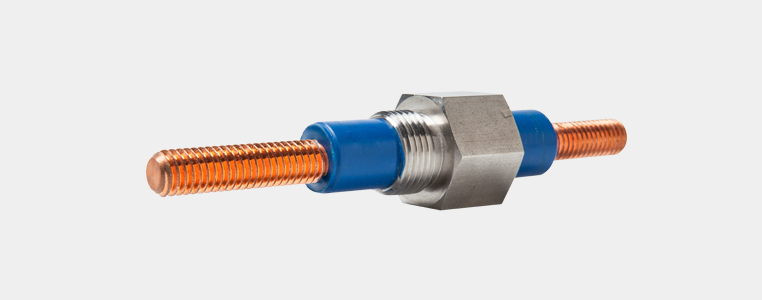

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

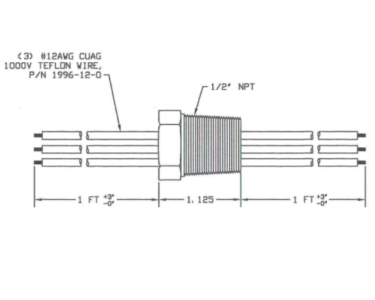

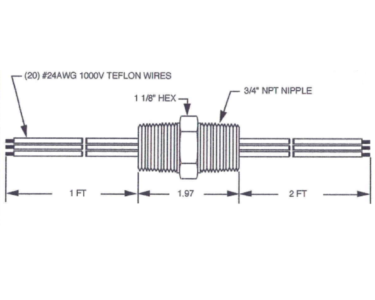

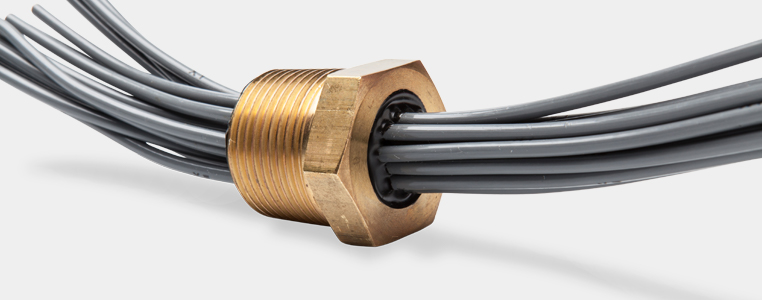

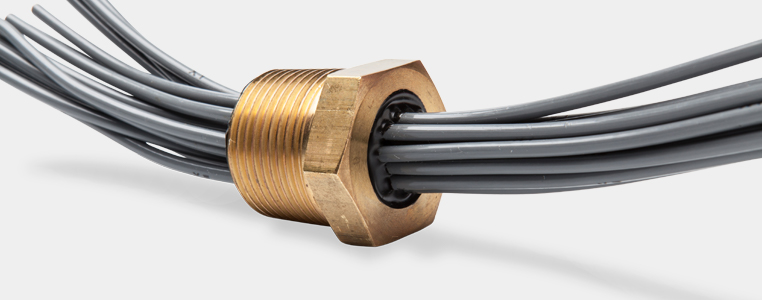

DuctorSeal Wire Feedthru

Multi-conductor hermetic wire feedthrough with NPT Threads

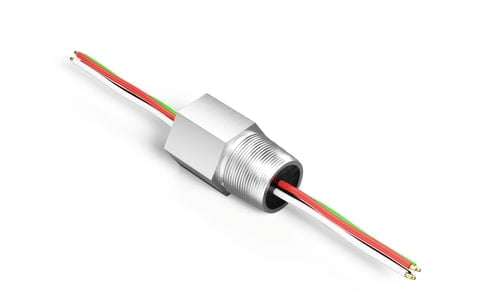

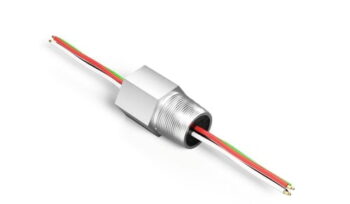

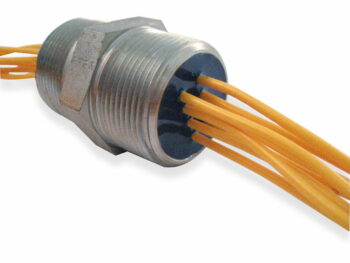

Explosion-proof NPT Wire Bushing

Side view of Explosion-proof NPT wire bushing with standard aluminum housing

Hermetic Coax Wire Feedthrough

Hermetic coaxial feedthrough with NPT threads and coaxial wires

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

Multi-Fiber Type Feedthrough

Hermetic fiber optic NPT feedthrough with SM and MM fiber in the same mechanical interface.

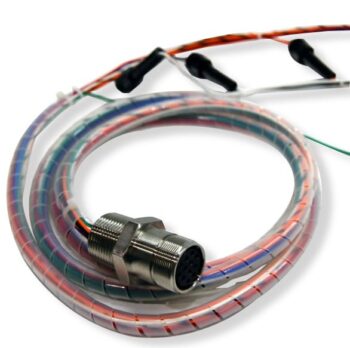

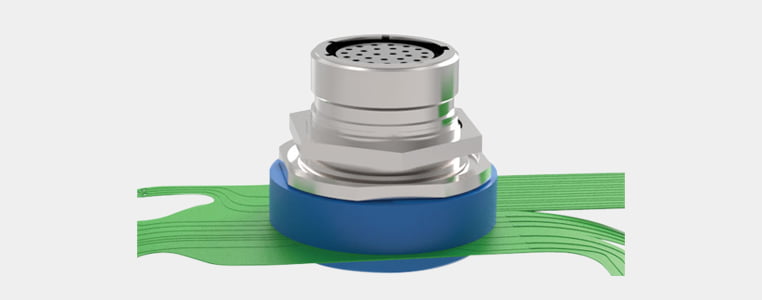

Connectorized NPT Feedthrough

Customized connector / wire feedthrough assembly with NPT bulkhead connection

Turnkey Terminated NPT Cable Feedthrough.

Designed for plug-and-play application

NPT Explosion-proof Cable Assembly

Explosion-proof conduit seal with NPT threads can be designed for hazardous locations including explosion-proof environments.

ASME Wire Feedthrough

Hermetic wire feedthrough in custom explosion-proof ASME housing

Oil and Gas Power NPT Feedthrough

Designed with larger gauge wire for power transmission

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Cryogenic Power Feedthrough

Cryogenic Feedthrough design with three power feedthroughs integrated into a custom flange.

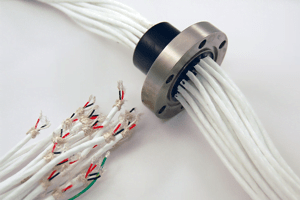

Electrical Feedthrough Harness

Customized electrical feedthrough with integral housing, wire, and electrical connection.

Custom Ribbon Cable Feedthrough

Ribbon cable feedthroughs create a simple plug-in design for customers integrating electronics inside a housing.

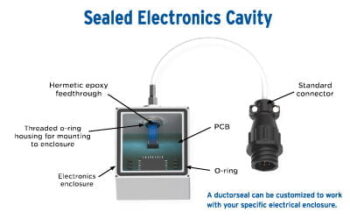

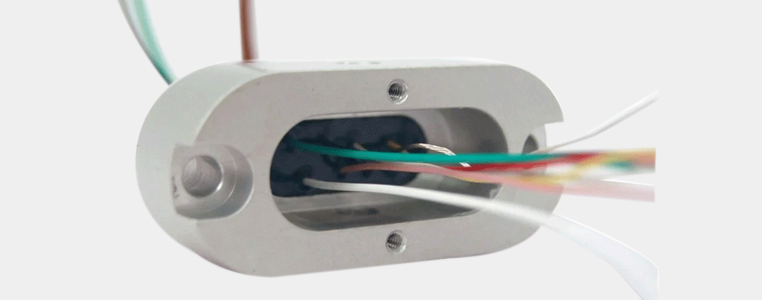

Sealed Electronics Cavity

Hermetically sealed housing from circuit board to wire assembly

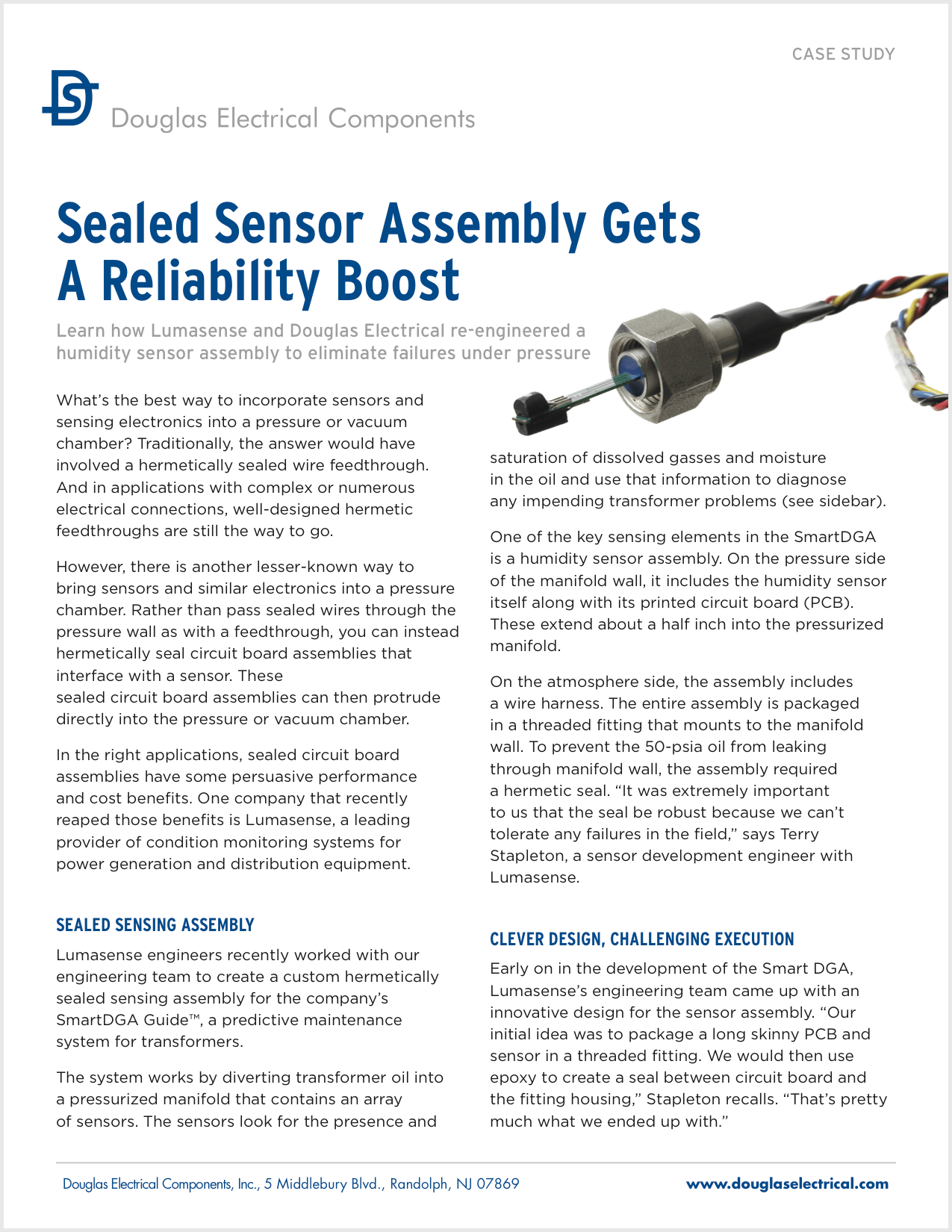

Hermetically Sealed Sensor Assembly

Hermetically sealed sensor assembly where the sensing element is exposed to the operating environment, but the housing and wire are hermetically sealed.

Sensor Hermetic Assembly

Hermetically sealed electrical feedthrough from PCB to cable in threaded housing

Multi-flex hermetic feedthrough

Multi-flex hermetic feedthrough circuit with face seal housing and jam nut

Hermetic NPT feedthrough with push/pull connector

Hermetic NPT electrical feedthrough with push/pull connector provides a compact footprint with inexpensive sealing method.

Hermetic M40 Face Seal Feedthrough

Custom hermetic PCB connector and circuit board hermetically sealed in M40 hermetic aluminum housing

Hermetic M12 Feedthrough with NPT Bulkhead Mounting

Connectorized 6 Position M12 hermetic cable assembly designed for NPT bulkhead mounting

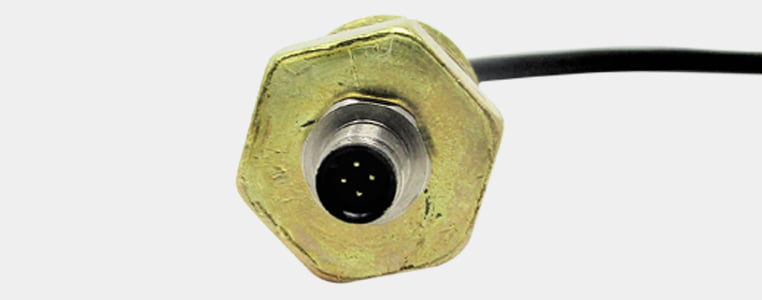

M12 Feedthrough Close-up

Epoxy-sealed NPT feedthrough plug with integral M12 cable assembly

Features

Certifications and Compliances

- Construction Standards for Explosion Proof Electrical Fittings

- IEC/EN 60079-0

- IEC/EN 60079-1

- IEC/EN 60079-2

- IEC/EN 60079-6

- IEC/EN 60079-7

ATEX Certifications

- ATEX Ex d

- ATEX Ex e

- ATEX Ex de

- ATEX Ex pD

CSA Standards

- CSA 22.2

- CSA E60079

UL Standards

- UL 1203

- UL 886

- UL 674

- UL 913

FM Approvals

- FM 3611

- FM 3615

- FM 3620

- FM 3610

Other Approvals

- IP-69 and above, NEMA 6P and above

Applications

- Wellhead sensors, enclosures, meters, computers, RTUs and instrumentation

- Natural gas, LN2, LNG, CNG, and H2 compressors, storage, and transportation

- Liquid and gas analyzers

- Cryogenic equipment

- ROVs

- Optical fiber instrumentation

Customization Options for Standard UL1203 Wire Bushings

- Standard Materials for Bodies: Choose from materials such as brass, aluminum, and specialty alloys.

- Plugs: Feraloy iron alloy and/or steel (standard); stainless steel (optional)

- Housing sizes (NPT): 1″, 1/2″, 3/4″ NPT

- Single or dual-threaded ends

- Wire types: PTFE and PVC

- Gauges: 3/0 to 24 AWG (hub size and wire count dependent)

- Wire count: 1 to 52 (hub size and wire gauge dependent)

Notes

- Integrate connectors and circuit boards to minimize assembly time.

- Hermetically seal electrical connections for cryogenic feedthrough applications.

- Customize your mechanical interface to integrate it into existing designs or new assemblies effectively.

Featured Products

Documents

Literature

Whitepapers

Versatile Hermetic Epoxy Seals Protect Fiber Optic Cable and Ensure Signal Quality

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations

Related Products

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of

up to 1,000 amps and 15kV.

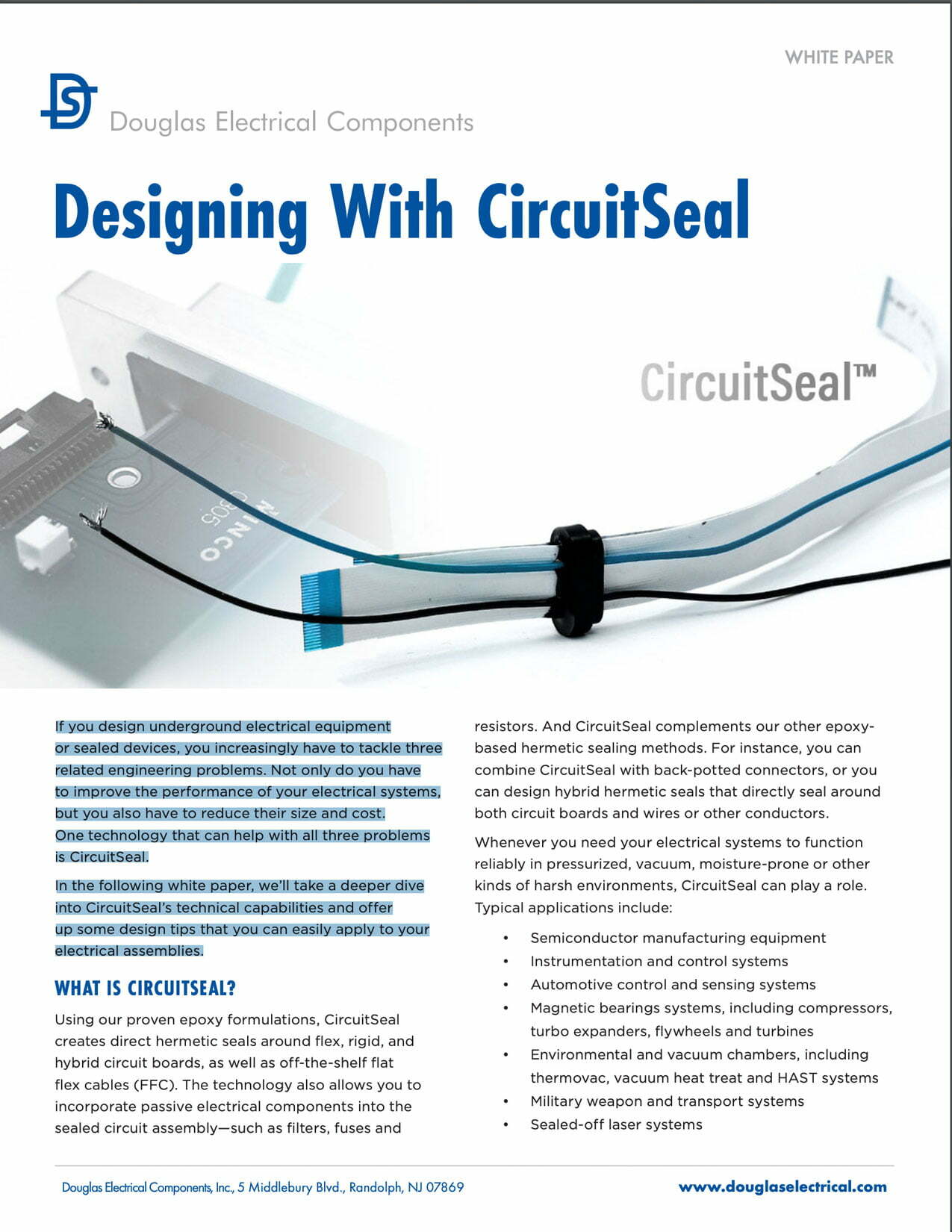

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

Liquid Tight Wire / Cable Feedthrough Seals

Create a high-density, sealed wire or cable electrical feedthrough

for use in hazardous and/or non-hazardous areas.

Explosion-proof wire and cable bushings

Sealed Line Bushings for Hazardous Locations

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

M8/M12/M23 Hermetic Connectors

Create a hermetically sealed electrical connection using an M8, M12 or M23 connector.

Thermocouple Feedthroughs

Create a hermetic thermocouple feedthrough in the exact configuration you need.