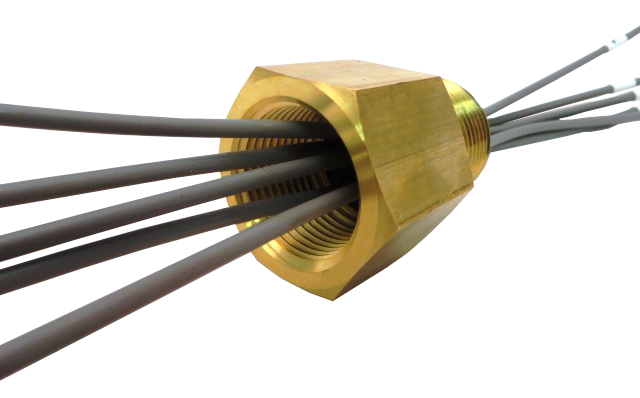

It’s tough enough to design safe electrical systems for hazardous locations without having to worry about the UL listings for each and every component you use. We’ve just made things a bit easier for you with a new line of UL listed explosion-proof wire bushings.

Our epoxy-based NPT bushings feature a UL 1203 listing, which addresses explosion-proof electrical equipment design. The UL listing saves you the step of certifying wire bushings for explosion-proof applications. But our UL 1203 bushings have two less obvious design features that can reduce your engineering effort when you need to pass wires or cables into or out of a hazardous location:

Improved crack resistance.

One issue with many previous explosion-proof designs is that they used cement-based sealants. Like many cements, these sealants can be prone to cracking and fatigue due to mechanical and environmental stresses. This limitation sometimes required compromises in the types of wire-and-cable products you could spec into explosion proof applications. Our UL 1203 bushings use epoxy seals, which are highly-resistant to fatigue cracking—and they have the added benefit of being chemically compatible with any wire-and-cable material in common use.

Combined explosion and process seal.

Most UL 1203 wire bushings seal against the direct causes of explosions such as sparks, flames or even dust. However, many applications in hazardous locations also need reliable process sealing—for example in a pressurized environment like a hazardous locations pump. In these applications, two seals are often needed, one for primary process sealing and a second for explosion proofing. We took a different, simpler approach. Our UL 1203 bushings handle the explosion proofing and provide a true hermetic process seal with leakage rates down to <1×10-9 cc-He/sec, application pressures up to 10,000 psi and burst pressures in excess of 15,000 psi.

Based on proven epoxy

Getting our NPT wire bushings listed to explosion-proof standards is just the latest step in making our products easier to use. We had previously received UL 1203 listing for our 7113–1481 epoxy formulation. This epoxy, which is used in the UL 1203 wire bushings, has been certified by UL for use in conduit fittings after passing the required chemical analysis and aging evaluation. And even before we had taken the step to pursue a standalone UL-listing, our customer have often used our epoxy-based feedthroughs, connectors, bushings and conduit fittings in a variety of equipment that complies with the stringent hazardous location requirements, including:

- IEC/EN 60079–0, IEC/EN 60079–1, IEC/EN 60079–2, IEC

- EN 60079–6 and IEC/EN 60079–7.

- ATEX Ex d, ATEX Ex e, ATEX Ex de, and ATEX Ex pD.

- CSA 22.2, CSA E60079.

- UL 1203, UL 886, UL 674 and UL 913.

- FM 3611, FM 3615, FM 3620 and FM 3610

Our line of UL 1203-listed wire bushings is available in 3/8- to 1-inch NPT sizes in brass, plated steel and stainless steel.

Custom Bushing Design Capability

For OEM customers looking to design in a customized wire bushing, Douglas Electrical can partner with you to achieve the rating within your application or system. Our team can customize the mechanical fitting, wire and cable types, and materials to align to the approval agency and design requirements. We will work through the process to either add the assembly to our existing file or create a wire bushing or seal to be included within your design.