Epoxy Feedthroughs

Hermetic Epoxy Feedthrough Technology

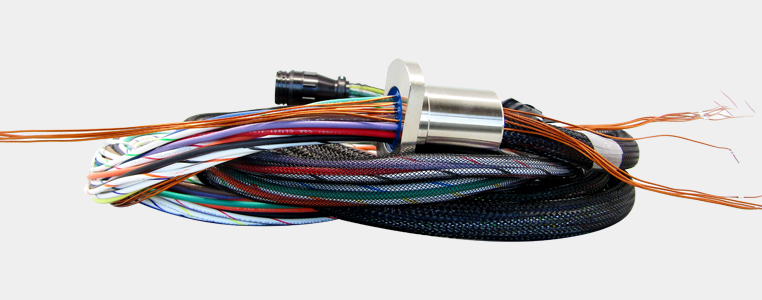

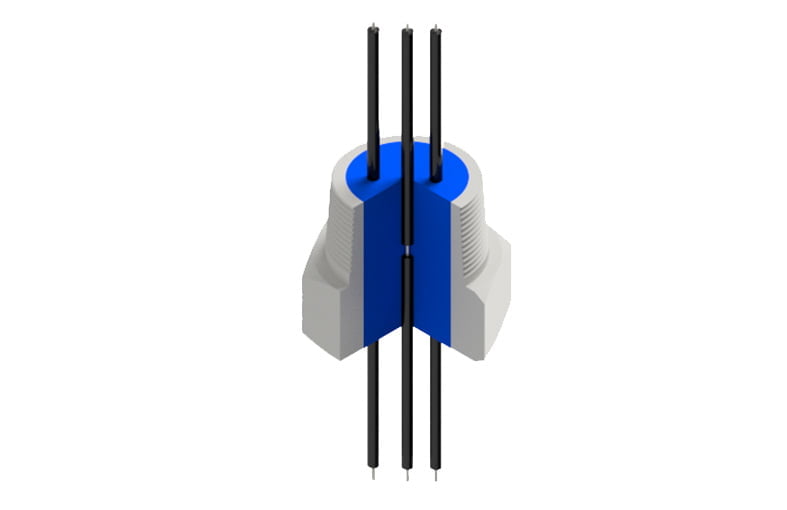

Douglas Electrical Components manufactures hermetic electrical feedthroughs using our proprietary low outgassing, hermetic epoxy. Our hermetic sealing process combines epoxy resin and a housing material such as stainless steel to encapsulate an electrical conductor such as a pin, stranded wire, or threaded stud. The conductor feeds through the opening with the epoxy curing through a thermal cycling process to create a hermetic seal. Various types of epoxies can be used, which can yield varying results in hermetic performance, chemical compatibility, and outgassing. Douglas Electrical employs a low outgassing material which is NASA certified low outgassing epoxy tested per ASTM E-595-93 (0.33% TML. 0.00% CVCM).

Epoxy technology is popular in a variety of environments, from cryogenic temperatures to 200°C. It permits an extremely high density feedthrough with the design flexibility to combine multiple conductor and connection types in a single assembly. This can reduce overall cost, from prototype through production.

One of the most attractive aspects of epoxy technology is its versatility and ability to be tailored to specific requirements. Douglas Electrical Components has the ability to hermetically seal to a variety of mechanical interfaces and materials. Epoxy is not as limited as other technologies in terms of its coefficient of thermal expansion (CTE). For example, our epoxy will hermetically seal directly to customer supplied housings, to be both cost efficient as well as create low-profile hermetic seals in tight spaces.

Epoxy feedthroughs are designed for hazardous locations and non-hazardous locations, sealing against liquids, gases, and dust in explosive atmospheres and a wide operating temperature range.

Specifications

| Sealing Method | 25mm2 x 1mm sample at 125°C vs optical condensing surface at 25°C, <1 x 10-6 mm Hg – RESULTS: <0.22% Wt Loss and <0.002% VCM. No visible deposits on the condensing plate. |

| Thermal Conductivity | 10 BTU in/hr ft 2°F |

| Volume Resistivity | 5×1016 Ω cm |

| Specific Gravity | 2.3 |

| Dielectric Constant | 60 Hz 6.5, 1 KHz 6.3, 1 MHz 5.9 |

| Thermal Expansion | 29 X 10-6 / °C |

| Maximum Service Temperature of Epoxy | 350°F (176°C) |

| Water Absorption

(per ASTM-D-570) |

<0.15% in 7 days |

| Dielectric Strength | 550v/mil |

| Water Vapor Transmission (Per ASTM-E96-80) | 0.7 ± 0.2 gms/m2/day, 0.125 mil sample thickness |

| Flame Resistance | UL File No. E92366 rated UL-94HB |

| L.O.C.A. Radiation Withstand | @ 1.5 x 106 Rads/hr for 200 x 106 Rads total. Leakage to He <3.0 x 10-8 Std cc He/sec, Pin-Pin resistance>1×1012Ω |

Design Capabilities

- Vacuum to 1×10-9 Torr

- Pressures as high as 15,000 psi

- Temperatures from -200°F to +350ºF

- Wire gauges from 38 AWG to 500 MCM

- Conductor counts from a single wire to 3,200 in a single feedthrough

- Cable lengths from stubs to 2,000 meters

- Seal to connectors, circuits, wires, pins, or a combination of connection types

- Chemical/Fuel/Gas/Radiation compatibility is proven