Alternative Energy

Hermetically seal electrical connections in today and tomorrow's energy solutions.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

Hermetic feedthroughs are an increasingly important technology in a variety of alternative energy applications—including smart grids, wind turbines, wave power systems, lithium batteries, hybrid vehicles, alternative fuel vehicles, charging and filling stations, solar energy, and magnetic bearing flywheels. Hermetic feedthroughs are designed to protect and seal from one environment to another. Electronics, wires, or power sources are being exposed to liquids and gases generating energy. Douglas Electrical partners with its customers in the alternative energy space to build customized solutions that enable the transmission of power or signal in these types of environments and new applications, from hydrogen to hermetically sealed battery compartments.

Alternative energy can mean better for the environment, yet also more challenging in terms of operating conditions. Douglas Electrical manufactures electrical feedthroughs for hazardous and non-hazardous environments. Gas storage systems including at cryogenic temperatures can require hermetic electrical seals between the gas and external environment. These seals often need third-party approvals to standards such as IEC 60079. Douglas Electrical components partners with customers to achieve the standard for customized feedthrough designs as well as offers a standard line of explosion-proof NPT feedthroughs.

While transformers are used in the traditional transmission and distribution market, Douglas also manufactures feedthroughs for this equipment used in alternative energy platforms. Windmills, as an example, use transformers to transmit power generated by the turbine. Douglas manufactures feedthroughs for power and signal applications using wires, connectors, or terminals. These seals can be used in both on and off-shore environments, with a hermetic epoxy designed and various housing options to survive the environmental conditions.

Locate a Technical Sales Engineer

Solution Images

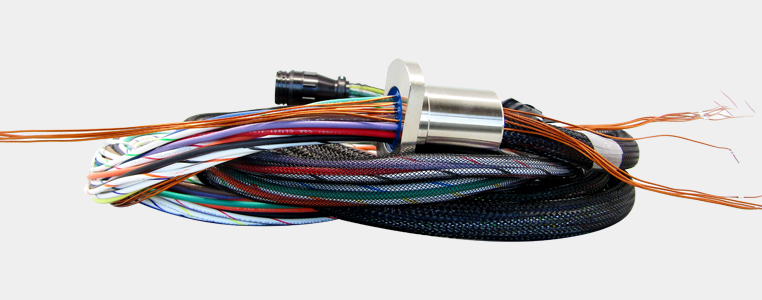

PotCon Power Feedthrough Assembly

PotCon hermetic power feedthrough assembly. Hermetically seal cables directly into the bulkhead connector assembly.

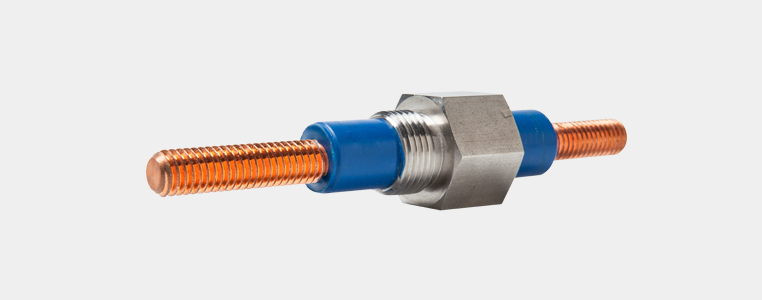

Motor High Power Terminal Seal

Motor high power terminal feedthroughs with NPT and copper studs work in compressors ranging in size from fractional horsepower to high-tonnage.

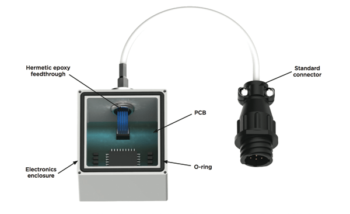

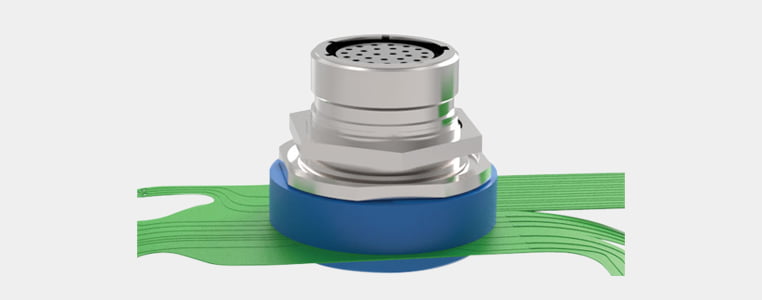

Sealed Electronics Cavity

Hermetically sealed housing from circuit board to wire assembly

Fiber Optic 38999 Connector

Integral optic fiber wire assembly with backpotted 38999 connector for plug-and-play use

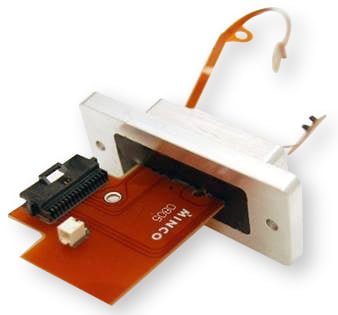

Circuit Board Sealed Assembly

Rigid-flex CircuitSeals reliably seal complex electrical packages based on flex PCB connectors that combine flexible and rigid sealer substrates.

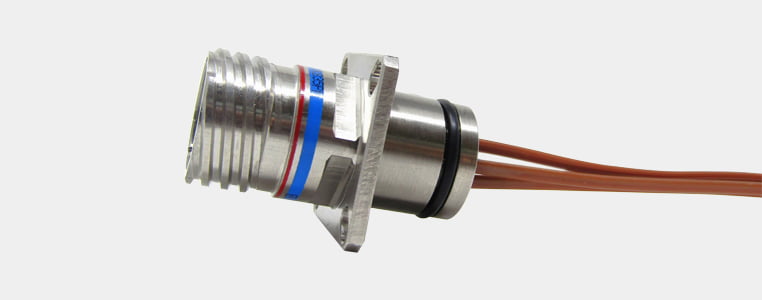

RBTW Waterproof Connector with NPT and wire leads

RBTW designed for environments that are submerged in water/liquid

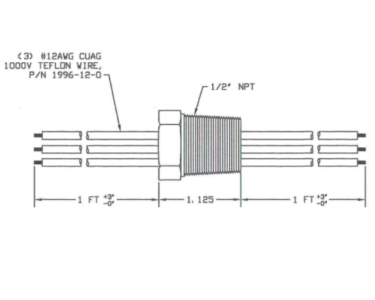

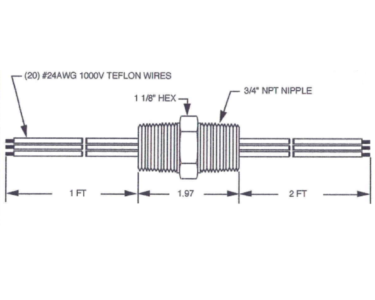

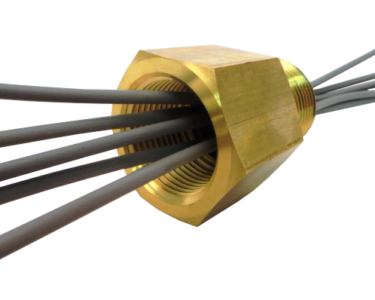

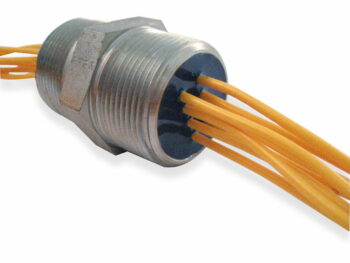

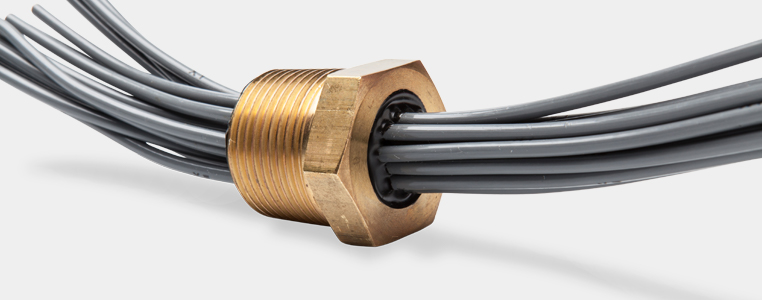

DuctorSeal Wire Feedthru

Multi-conductor hermetic wire feedthrough with NPT Threads

Cryogenic Wire Feedthru

Cryogenic wire feedthrough with JIC fitting allows for operation in high pressure and low temperatures.

OptiSeal threaded fiber optic hermetic feedthrough

OptiSeal threaded fiber optic hermetic feedthrough

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

Sealed Feedthrough Assembly

Hybrid JacketSeal-DuctorSeal feedthroughs are used in applications requiring both true hermetic sealing and fluid blocking—such as this hybrid feedthrough that seals both the vacuum chamber and heat transfer fluid for a magnetic bearing flywheel.

Hermetic Terminal Plate Assembly

Customized hermetic terminal plate assembly

Features

TECHNICAL ADVANTAGES

- One hundred percent testing for leak and electrical performance.

- Custom engineered sealing systems tailored to specific application requirements.

- Pressure ranges from 1×10-9 Torr to 15,000psi.

APPLICATIONS EXAMPLES

- Connector-to-wire hermetic wire feedthroughs using custom connectors and fused hermetic cable harnesses for smart grid infrastructures.

- Radial O-ring seals used for energy recovery in magnetic bearing flywheels.

- Magnetic bearing feedthroughs for wind turbines application.

- Hermetic vacuum seals for power and control cables in flywheel energy storage systems.

- Sealed electronic hermetic circuit board seal in wave and tidal power systems.

- Vacuum feedthroughs for photovoltaic panel manufacturing.

- Power transfer and performance monitoring for argon-filled lithium-ion batteries.

- Immersion cooling feedthroughs for server applications

- Automotive battery immersion cooling

Products

Documents

Whitepapers

Related Products

Wire & Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough

using virtually any conductor

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of

up to 1,000 amps and 15kV.

Custom Hermetic Flange & Plate Assemblies

Multi-port hermetic assemblies accommodate any feedthrough configuration,

with time and troubleshooting minimized.

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

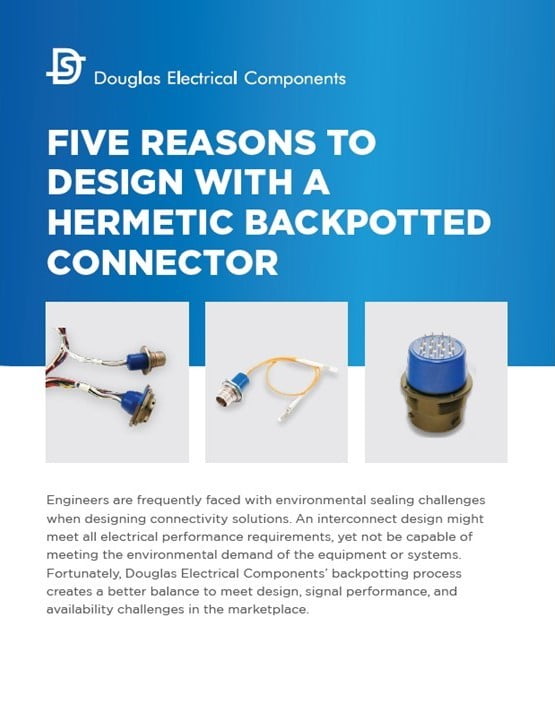

Backpotted Connector Assembly

All the benefits of a hermetic connector with a custom mechanical interface.