SAE Series SAE Feedthroughs

Hermetically seal connectors, wires, cables, terminals, circuits and optical fiber with an SAE mechanical interface.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- D-sub Connectors

- Micro-D Connectors

- 38999 Connectors

- Coaxial Feedthroughs

- M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

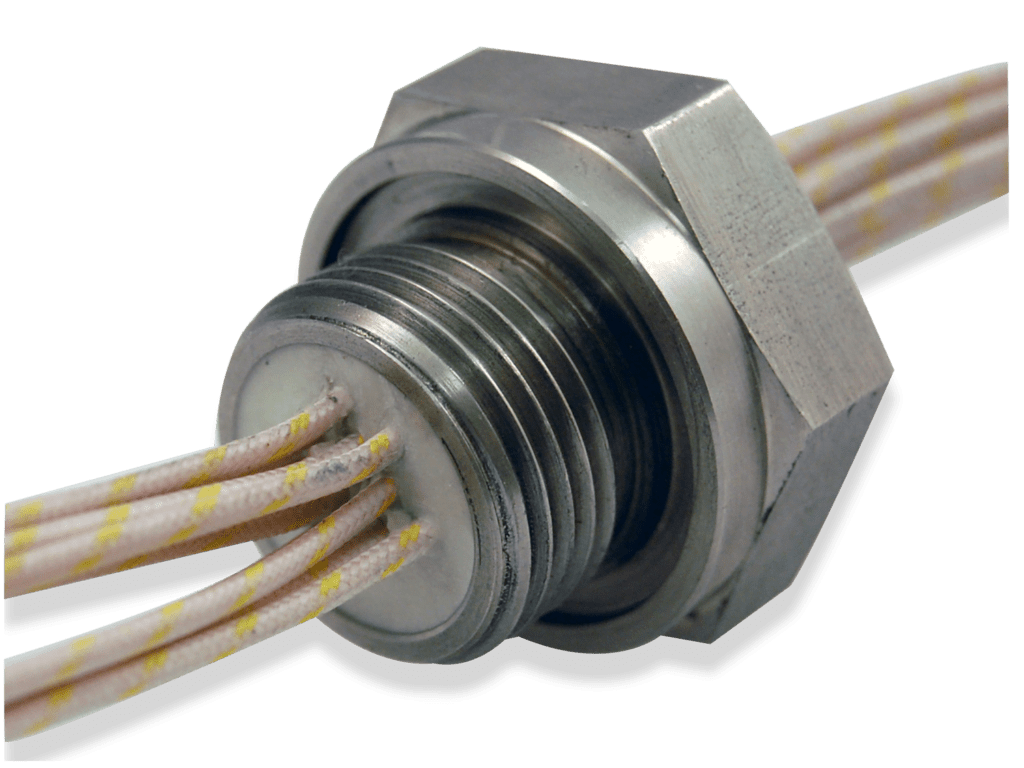

SAE (Standards for Automotive Engineers) threads are more common in industrial and automotive applications. For electrical feedthroughs, the preferred interface is an O-ring seal design versus a metal-to-metal seal with a tapered thread. SAE feedthroughs have an O-ring is installed between the thread and hex of the feedthrough. Straight threads engage with the mating surface and seal between the hex housing, O-ring, and mating surface. SAE feedthroughs can typically operate at higher pressures than NPT threads, but require more mating surface wall thickness to manage the pressure. Metric threads are also available in tapered and straight thread applications. The same materials and sealing methods are also available.

Douglas Electrical Components can hermetically seal a variety of electrical connections in an SAE configuration. Hermetic terminal seals are very popular for transmitting power in compressor and motor applications, utilizing SAE threads. Douglas offers a variety of standard configurations within the StudSeal motor terminal line.

Connectors, wires and circuits are also available in SAE feedthrough designs. Douglas can combine various types of electrical connections to simplify installation or retrofit existing designs. We source high quality electrical components to include in the design.

Locate a Technical Sales Engineer

Features

FEATURES

- Hermetically seal a variety of electrical connection types in vacuum and positive pressure environments

- Simple threaded installation

- Create a high density, hermetic wire feedthrough using our epoxy technology

- Hermetically seal optical fibers in pressurized environments

- Design connectors to either end of the feedthrough for plug-and-play connections

- Integrate flex or rigid circuits for OEM applications requiring a high density, lightweight design

SAE ADVANTAGES

- Designs for medium to high pressure

applications - Variety of threaded options

SAE DISADVANTAGES

- O-ring sealing technology in most common types

- More complicated thread machining can increase housing cost

- Requires thicker bulkheads

Products

FAQ

What is an SAE electrical feedthrough?

An SAE electrical feedthrough allows power or signal to “feed” or “pass” through from one end of a mechanical interface to another. In this case, the feedthrough uses an SAE fitting to mechanically interface with the device, control box, or wall.

Why would I choose an SAE feedthrough versus an NPT feedthrough?

SAE feedthroughs can typically operate at higher pressures. For customers with a preference to seal against an O-ring, the SAE fitting is a suitable option. NPT feedthroughs can require less wall thickness than an SAE fitting, so contact our engineers to discuss your application.

What materials are available?

Douglas has both in-house CNC machining as well as external suppliers; we can machine SAE fittings out of a variety of materials including stainless steel, high-strength nickel alloys, aluminum, and copper. Contact our engineers to review the pressure, temperature, and liquid or gas compatibility requirements to ensure that the correct fitting is designed.

How can I calculate the wire density capabilities within the feedthrough?

Contact our sales engineers; our team can confirm the wire density of a feedthrough based on the inside diameter hole, wire gauge, and conductor count. Our technology creates a high-density solution, minimizing the number of feedthroughs required or the space and weight of the feedthrough itself.

How is Douglas hermetically sealing to the electrical connection?

Douglas uses a high-strength hermetic epoxy to hermetically seal to the electrical connection. For wire applications for example, our epoxy bonds directly to the conductor to prevent any leaks in vacuum or positive pressure. This performs beyond a water-tight connection.

Image Library

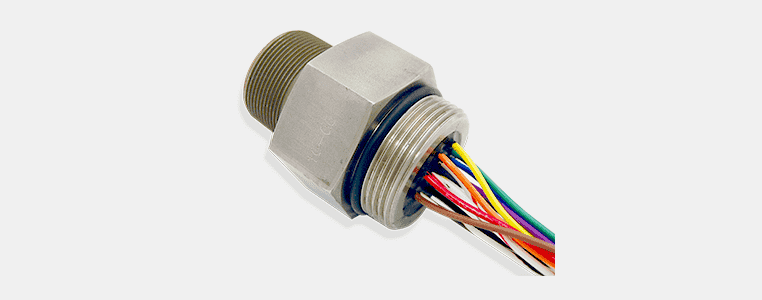

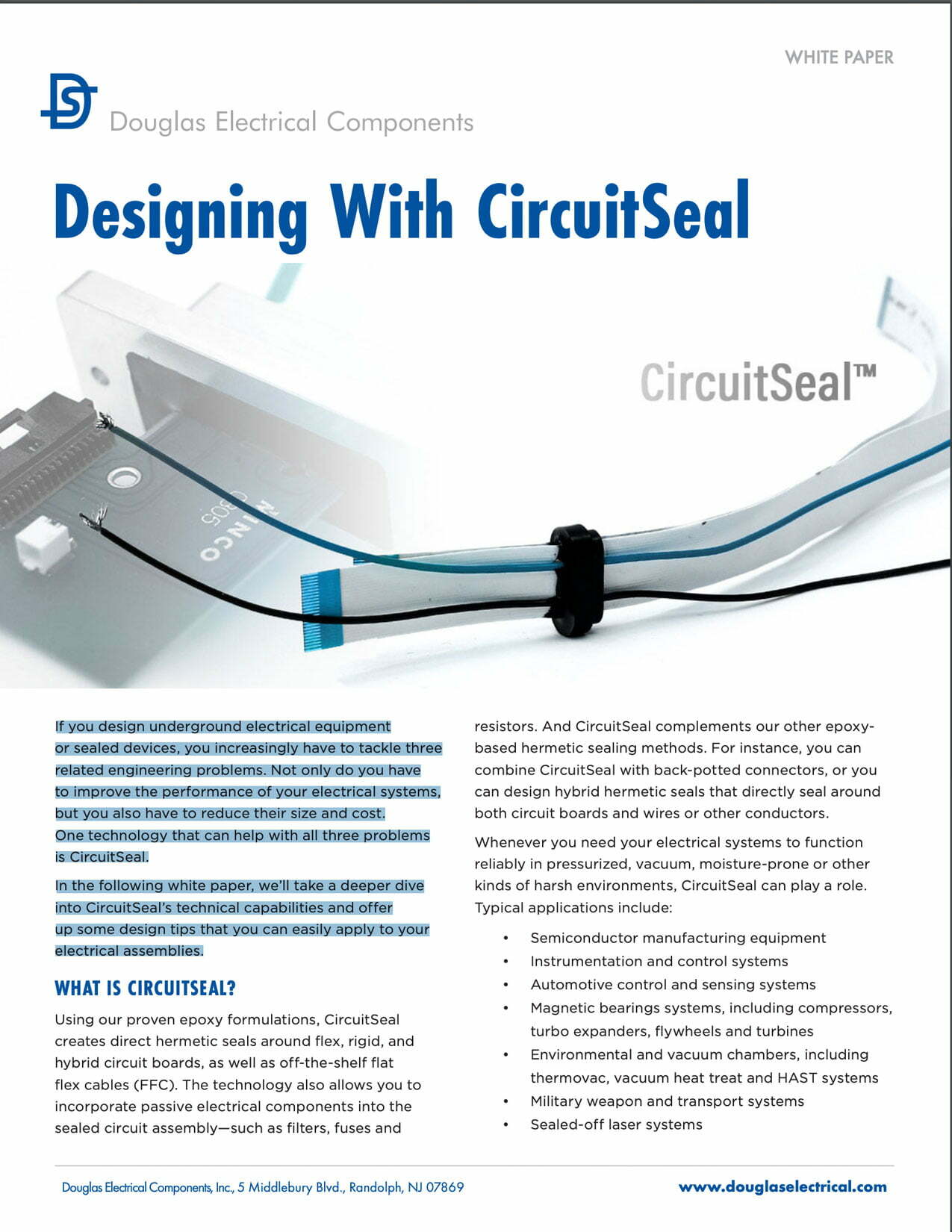

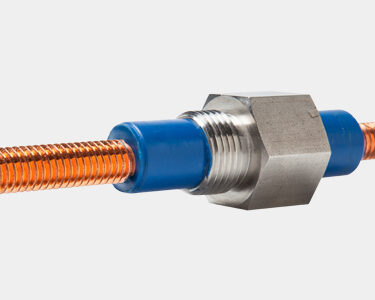

SAE threaded hermetic wire to cable feedthrough

SAE threaded hermetic wire to cable feedthrough. Use braided cable assemblies to protect against harsh environments while mounting wires or fibers on the opposite side of the bulkhead.

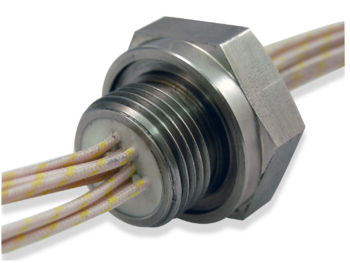

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

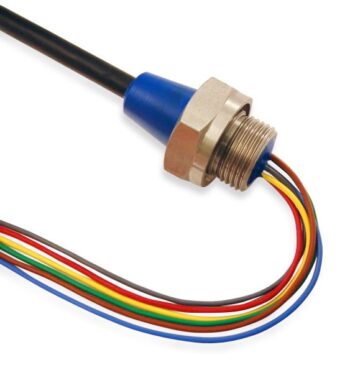

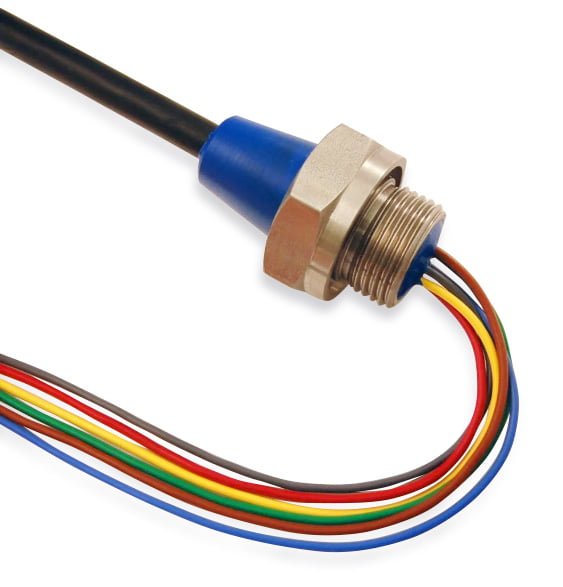

Hermetic SAE Wire Feedthrough

Hermetically sealed wire assembly through SAE housing with integral connectors

PotCon SMA hermetic feedthrough connector

PotCon SMA hermetic feedthrough connector with UNF thread. Select single connection feedthroughs or integrate into a larger plate assembly.

High Temperature Feedthru Capabilities

Design feedthroughs with high temperature wires.

Hermetic Flex Feedthrough

Hermetic flex feedthrough with threaded bulkhead fitting

Backpotted BNC connector

Hermetic BNC-99 connector with integral wires

OptiSeal Feedthrough

OptiSeal Hermetic FIber Optic Feedthroughs

Documents & Downloads

Literature

Whitepapers

Certificates & Standards

PDF Catalog

PDF Catalog