MIL-DTL-24308 D-sub Connectors

Plug-and-play hermetic D-sub connector with reversible mounting.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

The D-sub connector remains an industry standard in the hermetics space for a variety of applications. Douglas Electrical Components manufactures a standard product line of hermetic D-sub connector feedthroughs for a variety of applications to interface with standard MIL-DTL-24308 connectors under vacuum and positive pressure. These feedthroughs create a plug-and-play electrical connection for vacuum systems. With D-sub connectors on both sides of the feedthrough, engineers and system integrators save time and effort, eliminating the need for soldering miniature connector wires or solder cups.

OEM & Custom D-Sub (MIL-DTL 24308) Hermetic Connectors

Combine any number and configuration of D-sub connectors into the mechanical interface of your choice. Douglas will hermetically seal any D-sub connector pin count into a housing; in many cases the D-sub connector is also specified with other connection types, minimizing the number of penetrations into a chamber, panel, or glovebox. Our D-sub connectors are specified to meet MIL-DTL-24308 standards.

Custom designs are available for low profile mounting applications in OEM equipment including MIL/Aero and Semiconductor manufacturing.

D-sub plugs or receptacles can be combined with a variety of interfaces including connectors, wires, cables, and flex circuits. Contact our technical sales engineers to review your requirements in more detail.

Standard Vacuum D-Sub Connectors

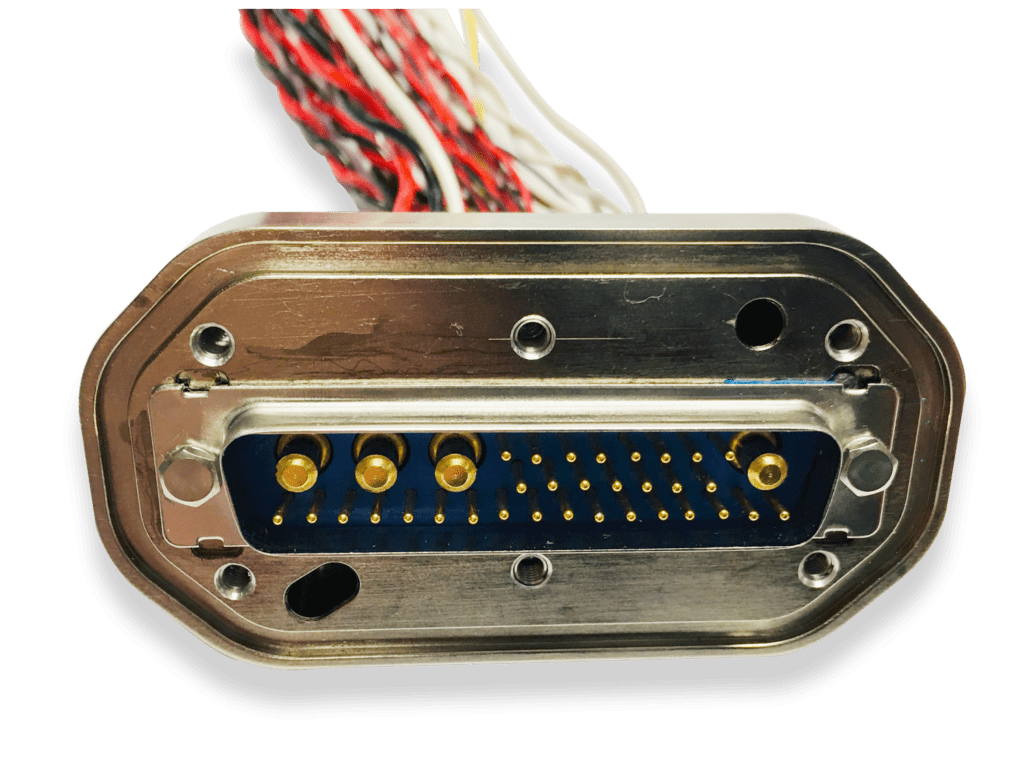

Manufactured with an aluminum housing, our hermetic D-sub connector feedthrough line seals with a standard Viton+ O-ring; the housing is designed with O-ring grooves on either side of the housing to be fully reversible and simplify installation. The feedthrough is designed with stainless steel, electroless nickel plated steel, or gold-plated brass shell connectors.

The connectors are pinned straight through the housing, such that Pin 1 on the vacuum connector is fed to Socket 1 on the atmospheric side. Standard leak rate is < 1×10-9 cc He/sec with higher performance available. All standard D-sub pin counts and connectors are available. Our solutions are designed to interface with standard MIL-DTL-24308 connectors.

FEATURES

- Plug-and-play with two connectors in a hermetic package

- Hermetically sealed and 100% tested

- Reversible design to increase mounting options

- 4-6 Week lead team AAO (After Acceptance of Order); contact for expedited service

SPECIFICATIONS

| Shell material | Stainless-steel or Nickle plated steel up to 78 pins; gold-plated brass for 104 pin-count |

| Mounting bolt holes | 4x M3.0x5 0.335 full thread depth (bolts not included) |

| Connector material | Electroless nickel plated aluminum shell |

| Connector feedthrough configuration | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment |

| Feedthrough connection | Straight-through design; Pin 1 (vacuum) to

Socket 1 (atmosphere), standard |

| Leak rate | < 1×10-9 cc He/sec. Contact factory for more options. |

| Operating temperature | -40°F to 225°F (-40°C to 107°C) |

| Current rating | 3A per contact in air |

| Voltage resistance | 600 VAC |

QUALITY

- ISO9001 / 140001

- RoHS / REACH compliant

- <1×10-9 cc He/sec

Image Library

Dual D-sub Hermetic Connector

PotCon Dual sub-D hermetic connector on rectangular flange creates a higher density connection with a single penetration point.

hermetic D-sub connector Side View

hermetic d-sub connector feedthrough

Vacuum Wire Feedthrough & Electrical vacuum feedthrough

Hybrid Hermetic D-sub Connector PotCon

Combination hermetic power and signal connectors allow all electrical needs through a single penetration.

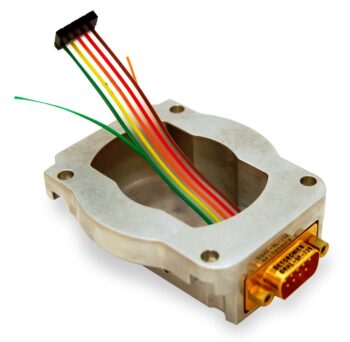

RBTW custom d-sub seal in customer housing

RBTW custom d-sub hermetic seal with integral wires. The hermetic connection is installed in a customer designed and supplied housing.

Hermetic D-sub Portplate Electrical Feedthrough Assembly

Hermetic Portplate Electrical Feedthrough Assembly with 10 D-sub Connectors

CF Feedthrough with RJ45 and D-sub connectors

Vacuum view of CF hermetic feedthrough featuring RJ-45 and D-sub connectors

Custom CF D-sub Tube feedthrough

Unique hermetic solutions aimed at maximized signal density in vacuum chambers with limited space.

D-sub & RJ45 CF Feedthrough

CF electrical feedthrough with D-sub and RJ45 ethernet connectors

D-sub & Micro-D Bulkhead Feedthrough

Combine various hermetic connectors into a single design, including Micro-D and D-sub connectors.

CF feedthrough with RJ45 and d-sub connector

CF feedthrough with RJ45 and d-sub connector; combine various connection types with minimal to no tooling.

D-sub Hermetic Flange

D-sub hermetic flange feedthrough assembly. Integrate D-sub connectors as part of the flange or order independent connectors with reversible mounting.

Featured Standard Products

D-sub Connectors Configurations

View our standard D-sub feedthrough configurations. For further customization, our team is ready to help tailor products to meet your needs.

| Product Name | Housing Material | Mounting bolt holes | Connector feedthrough configuration | Housing Type | Conductor Count | Shell Size | Current rating | Vacuum Leak | Electrical Hipot |

|---|---|---|---|---|---|---|---|---|---|

| 54675 104-Pin Hermetic D-sub Connector | Aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 104 | 6 | 3A per contact in air | < 1×10-8 cc He/sec. Contact factory for more options | 600 VAC |

| 54674 78-Pin Hermetic D-sub Connector | Aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 78 | 5 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54673 62-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 62 | 4 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54669 50-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 50 | 4 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54672 44-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 44 | 3 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54668 37-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 37 | 4 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54671 26-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 26 | 2 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54667 25-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 25 | 3 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54670 15-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 15 | 2 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54666 15-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 15 | 2 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

| 54665 9-Pin Hermetic D-sub Connector | Stainless-steel or aluminum | 4x M3.0x5 0.335 full thread depth (bolts not included) | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | Face Seal with O-ring | 9 | 2 | 3A per contact in air | < 1×10-9 cc He/sec. Contact factory for more options. | 600 VAC |

FAQ

Will Douglas Electrical customize a D-sub connector feedthrough?

Yes. Douglas Electrical Components customizes most of our hermetic connectors and feedthroughs. The process is relatively simple. Partner with a technical sales engineer to define your application, mechanical requirements, and the types of interconnects, whether wire, cable, fiber, connectors, or terminals. Our team will develop a design that fits the application requirements. Custom D-sub feedthroughs are commonly customized, whereas the reversible feedthrough is designed for the convenience of a standard package.

How do I install the D-sub feedthrough?

Refer to the datasheet for dimensional data as well as the panel cutout guidelines. The part number table will refer you to the correct D-sub housing size to select your panel cutout.

What are the standard materials offered?

Stainless steel and aluminum are the standard materials available for the housing. Contact the factory for more options. We customize hermetic D-subs for various applications and industries requiring specialty metals as well as certain plastics for custom applications.

Do you have a Micro-D version of this connector?

Yes, here is the link to the Micro-D hermetic connector.

Documents & Downloads

Documents