DuctorSeal® Series Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

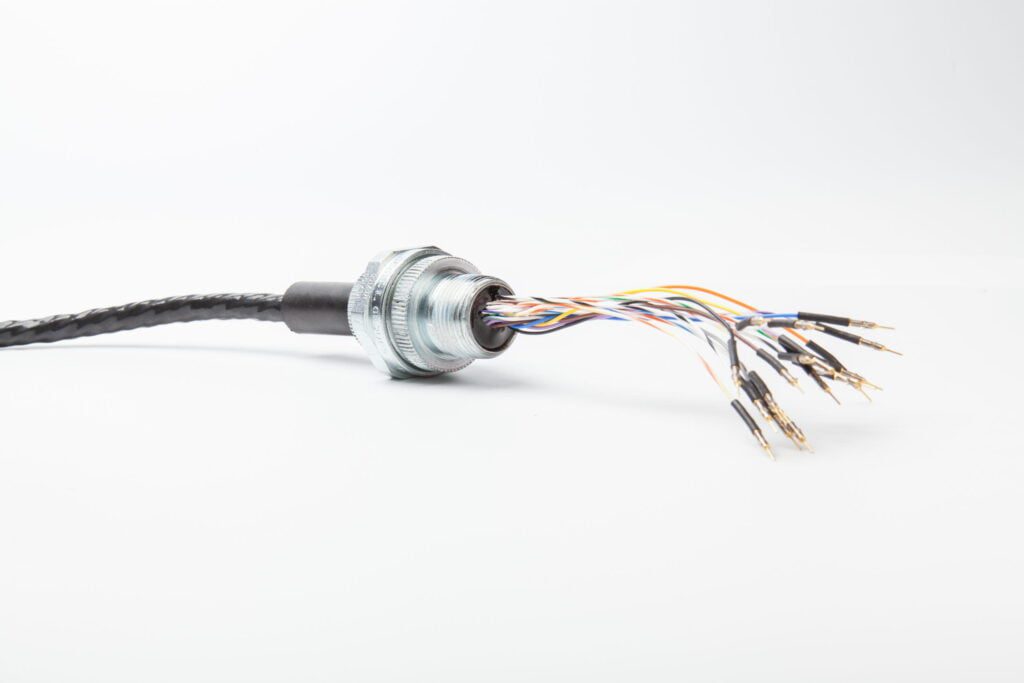

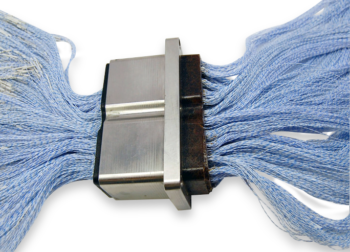

DuctorSeal® hermetic wire feedthroughs and sealed cable assemblies provide custom, liquid- and gas-tight electrical pass-throughs for various applications. Our hermetic feedthroughs come pre-wired and pre-tested, ensuring seamless drop-in use. DuctorSeal supports virtually any electrical connection combination on vacuum and atmospheric sides, accommodating conductor counts of up to 3,000 wires for demanding applications. Hermetically seal directly to the conductor to create a robust, sealed feedthrough with ultimate design flexibility. Integrate virtually any cable assembly options including termination, jacketing/shielding, and connectorization to have a drop-in, pre-tested hermetic feedthrough ready for install.

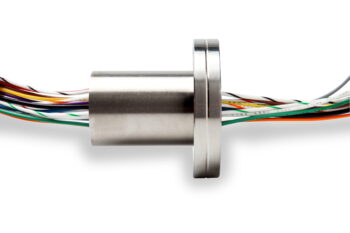

Ultimate Design Flexibility

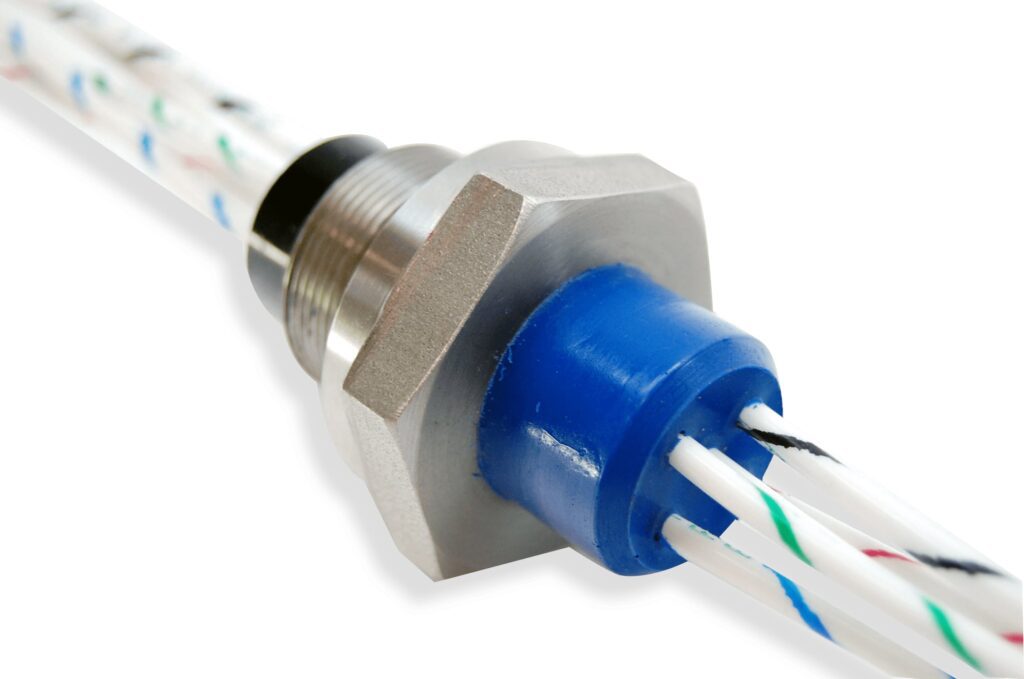

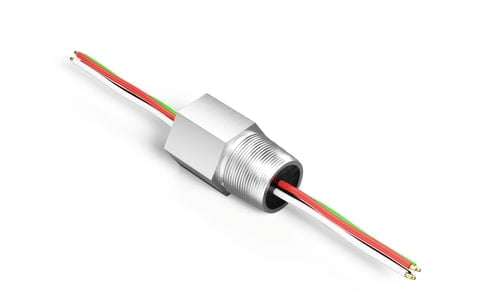

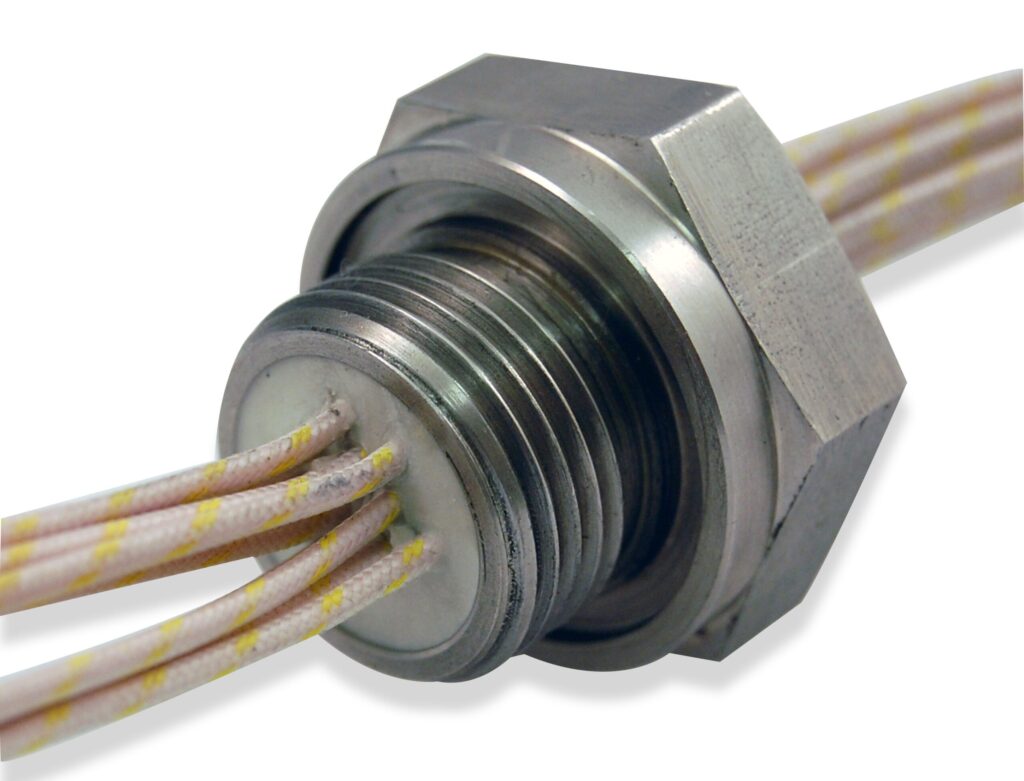

Each end of the bulkhead wire feedthrough can be customized to feature wires, jacketed cables, or connectors, with the hermetic sealing point located within the epoxy of the bulkhead at the conductor. DuctorSeal’s epoxy-sealed feedthroughs are designed to meet leak-rate requirements, even in stranded wire applications, and comprise precision-machined housings made from materials such as aluminum, titanium, stainless steel, brass, specialty alloys, and plastic. A variety of mechanical interfaces are available including threaded connections, flanges, and customized fittings.

To simplify installation, Douglas Electrical Components offers integrated terminals and connectors at each end of the wires and cables, saving time on the factory floor or in the field. If you’re potting cables in your operation, Douglas offers the expertise to do this process efficiently, with fully tested assemblies ready for use. Virtually any connector type can be integrated, with Douglas sourcing all components according to your needs.

Single Conductor Feedthrough

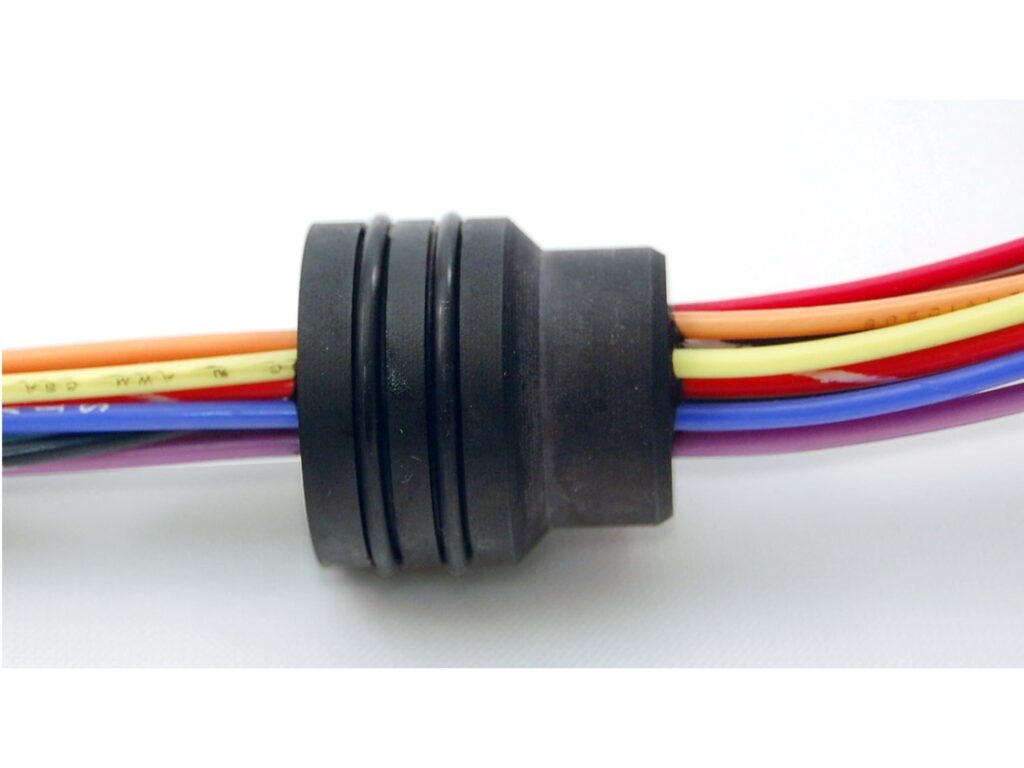

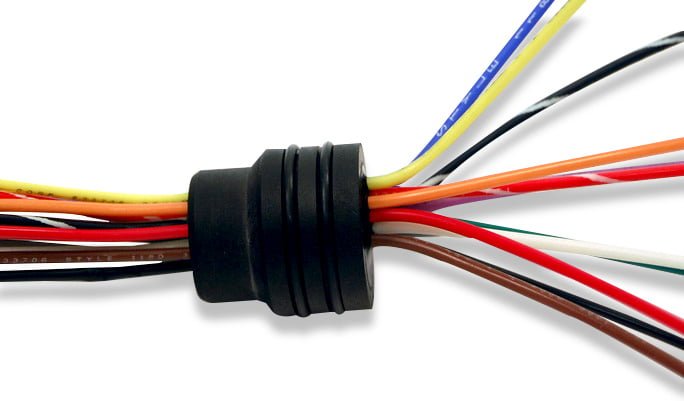

Multi-Conductor Cable Feedthrough

Douglas Electrical Components manufactures multi-conductor cable feedthroughs, hermetically sealing each individual conductor to provide better signal integrity than additional connectors or pin headers. This option also increases design flexibility and reduces costs for critical applications.

Our custom hermetic feedthroughs can withstand a range of environments, with vacuum capabilities from 1×10-10 Torr to pressures of 15,000 psi. Operating temperatures range from 4 K (LHe) to 200°C. High voltage and low cross-section sealed wire feedthroughs operating up to 30kV-DC are also available.

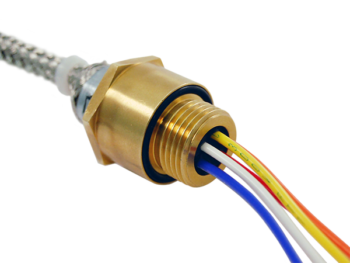

High Pressure Feedthroughs

High pressure electrical feedthroughs are commonly designed using wires and cables within the pass through assembly. Douglas manufactures its high pressure wire feedthroughs to withstand pressures up to 15,000 PSI (1,000 bar) in various mechanical interfaces including threaded connections and radial O-ring seals. While epoxy is not commonly associated with high pressure feedthroughs, Douglas manufactures high pressure wire feedthroughs to be utilized as a high pressure vessel electrical feedthrough to transmit power or signal in and out of the vessel or pressurized container. This can include cryogenic tanks and systems. Additionally, our hermetic wire feedthroughs are designed to operate in applications in hazardous locations, carrying certifications for explosive atmospheres, including the high pressure cable pass through for enhanced functionality.

Designs for Hazardous Locations

DuctorSeal hermetic wire feedthroughs are available as standard and custom options for hazardous locations. We offer UL/cUL Class I Division 1 explosion-proof conduit seals with wires from 24 AWG to 3/0 AWG in various conductor lengths and colors. ATEX and IECEx line bushings are available in NPT and metric threaded configurations through our 57754 series.

Additionally, our team can custom-design a feedthrough to help achieve an explosion-proof rating for your system, analyzer, sensor, or transmitter. Contact us with details on your application to get started.

Features

WIRE FEEDTHROUGH PERFORMANCE CAPABILITIES

- Uses the same wire and insulation types already approved for use elsewhere in your system

- <1×10-9 cc/sec per feedthrough

- Pressures of 15,000 psi

- Operating temperatures range from 4 K (LHe) through high temperatures of 200°C

- High-voltage cables up to 30,000 V

- Full cable harness options with connectorization available

COMMON HOUSING TYPES

- NPT

- Face seals

- Radial O-rings

- SAE

- CF flange

- QF/KF flange

- Customer supplied housings

- ANSI flange

- Custom options available

COMMON WIRE & CABLE TYPES

- Individual wires (PTFE, PVC, etc.)

- Jacketed cable

- Coaxial feedthroughs

- Thermocouple

- Customized assemblies with integral connectors

- Visit our OptiSeal page for Fiber Optic Feedthroughs

MARKET CAPABILITIES

- ISO 9001:2015

- ISO 14001:2015

- AS9102 First Article Inspections available upon request

- 100% quality control testing to IAW MIL-STD-810

- IPC-620 certified technicians provide cable harness work like labeling, bundling, twisting, shielding, filtering, soldering, and crimping

- ITAR DDTC Registration

- UL/cUL 1203, UL 886, UL 674, and UL 913 + ATEX and IECEx certifications

- NASA ASTM-E-595 certified low-outgassing epoxy (0.33% TML, 0.00% CVCM)

- Conflict Materials and ROHS-compliant

Featured Products

Hermetic Wire / Cable Feedthroughs Configurations

View our standard DuctorSeal® Series feedthrough configurations. For further customization, our team is ready to help tailor products to meet your needs.

| Product Name | Housing Material | Housing Size | Housing Type | Wire Type | Wire Gauge | Conductor Count | Vacuum Leak | Electrical Hipot | Pressure Limit* |

|---|---|---|---|---|---|---|---|---|---|

| 28103 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2500 PSI |

| 28050 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28102 – 10 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 10 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28049 – 10 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 10 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28064 – 5 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 5 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28012 – 5 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 5 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28100 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28078 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28063 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28054 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28047 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28026 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28011 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28002 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28099 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28046 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28077 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28025 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28095 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28094 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28075 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28042 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28023 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28020 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28088 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28059 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28036 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28007 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28085 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28032 – 12 Position Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28055 – 3 Position Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 3 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28052 – 3 Position Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 3 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28003 – 3 Position Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 3 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28001 – 6 Position Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28315 – 60 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Thermocouple Teflon® Insulation ISA Type E,J, K or T | 24 AWG | 60 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28312 – 20 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Thermocouple Teflon® Insulation ISA Type E,J, K or T | 24 AWG | 20 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28310 – 5 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Thermocouple Teflon® Insulation ISA Type E,J, K or T | 24 AWG | 5 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28309 – 2 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Thermocouple Teflon® Insulation ISA Type E,J, K or T | 24 AWG | 2 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28306 – 12 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 12 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28302 – 20 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 20 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28301 – 12 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28297 – 20 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 20 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28293 – 32 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 32 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28292 – 20 Conductor Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 20 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28288 – 10 Position Conflat Hermetic Wire Feedthroughs | Stainless Steel | 1.33″ | Conflat flange | Thermocouple Teflon® Insulation ISA Type E,J, K or T | 24 AWG | 10 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | |

| 28287 – 5 Position Conflat Hermetic Wire Feedthroughs | Stainless Steel | 1.33″ | Conflat flange | Thermocouple Teflon® Insulation ISA Type E,J, K or T | 24 AWG | 5 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | |

| 28284 – 3 Position Conflat Hermetic Wire Feedthroughs | Stainless Steel | 1.33″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 3 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | |

| 28285 – 6 Position Conflat Hermetic Wire Feedthroughs | Stainless Steel | 1.33″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 6 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | |

| 28276 – 12 Position Conflat Hermetic Wire Feedthroughs | Stainless Steel | 1.33″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 12 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | |

| 28023 Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 16 AWG | 12 | - | 1000VAC | - |

| 28321 Hermetic Wire Feedthrough | Stainless Steel | 1”-20 | Vacuum face seal with Nitrile O-ring | - | 20 AWG | 3 | - | 1000VAC | - |

| 28043 Hermetic Wire Feedthrough | Brass | 1″ | NPT Nipple | - | 16 AWG | 20 | - | 1000VAC | - |

| 28081T Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 24 AWG | 12 | - | 150VAC | - |

| 28174 Hermetic Wire Feedthrough | Stainless Steel | 1/16″ | SAE | - | 20 AWG | 12 | - | 1000VAC | - |

| 28335J Hermetic Wire Feedthrough | Stainless Steel | 1”-20 | Vacuum face seal with Nitrile O-ring | - | 24 AWG | 10 | - | 150VAC | - |

| 28165K Hermetic Wire Feedthrough | Stainless Steel | 3/4″ | SAE | - | 24 AWG | 2 | - | 150VAC | - |

| 28353 Hermetic Wire Feedthrough | Stainless Steel | 1 1/4”-18 | Vacuum face seal with Nitrile O-ring | - | 16 AWG | 32 | - | 1000VAC | - |

| 28071 Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 20 AWG | 12 | - | 1000VAC | - |

| 28184T Hermetic Wire Feedthrough | Stainless Steel | 1 1/16” | SAE | - | 24 AWG | 20 | - | 150VAC | - |

| 28160 Hermetic Wire Feedthrough | Stainless Steel | 3/4″ | SAE | - | 24 AWG | 12 | - | 1000VAC | - |

| 28068 Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 24 AWG | 20 | - | 1000VAC | - |

| 28338T/4/4 Hermetic Wire Feedthrough | Stainless Steel | 1″-20 | Vacuum face seal with Nitrile O-ring | - | 24 AWG | 40 | - | 150VAC | - |

| 28195T Hermetic Wire Feedthrough | Stainless Steel | 3/4” | Vacuum face seal with Nitrile O-ring | - | 24 AWG | 5 | - | 150VAC | - |

| 28163/6/4 Hermetic Wire Feedthrough | Stainless Steel | 3/4” | SAE | - | 12 AWG | 3 | - | 1000VAC | - |

| 28090/4/6 Hermetic Wire Feedthrough | Brass | 1″ | NPT Nipple | - | 20 AWG | 20 | - | 1000VAC | - |

FAQ

What is a hermetic feedthrough?

Hermetic is defined as any enclosure that prevents gasses and liquids (fluids) from migrating across the bulkhead. A common industry leakage rate is <1×10-8 cc-Helium/second. A hermetic electrical feedthrough will need to limit leakage from one side (vacuum pressure) to the other (atmospheric). Douglas customizes feedthroughs using a hermetic epoxy to seal within the bulkhead between pressure/vacuum and atmosphere. DuctorSeal is a product focused on the hermetic sealing of wires and/or cables within the bulkhead down to the conductor.

What is a hermetic wire feedthrough?

A hermetic wire feedthrough is a type of electrical connection that is used to transmit electrical signals or power through a hermetic seal. A hermetic seal is a barrier that prevents the exchange of gases or liquids between the inside and outside of an enclosure, and is often used to protect components or devices from external factors such as moisture, dust, or contamination. Douglas will hermetically seal virtually any wire or cable conductor type using its low-outgassing, hermetic epoxy.

Is DuctorSeal used as a bulkhead wire feedthrough?

Yes. DuctorSeal is designed as a hermetically sealed bulkhead wire feedthrough. It can be integrated with virtually any mechanical interface. Bulkhead wire feedthroughs are commonly installed control panels and cabinets to prevent moisture and gases from penetrating the system while feeding power or signal in or out of the system. DuctorSeal provides the hermetic seal at the conductor within the bulkhead to completely protect the system. This is a step beyond where a traditional cement-based seal will protect.

What is a vacuum feedthrough?

A vacuum feedthrough is a more specific type of hermetic feedthrough. The bulkhead fitting is sealed and tested to ensure a hermetic seal between the vacuum pressure side of the feedthrough and the atmospheric side. Vacuum feedthroughs are common in vacuum systems, semiconductor equipment, gloveboxes, and space simulation systems. As more systems integrate instrumentation and sensors directly into the testing environment, electrical feedthroughs need to maintain the vacuum pressure environment. Vacuum feedthroughs typically integrate vacuum flanges such as CF flanges or KF flanges. These mechanical interfaces are offered in standard sizes that integrate into industry systems that often come with pre-populated ports. Other fittings are also possible including radial O-ring seals, which offer a smaller footprint.

What are the advantages of an epoxy-based seal over a glass-to-metal seal?

Epoxy based seals allow more flexibility in design. Conductors can pass directly through the epoxy, allowing a simpler assembly process. Epoxy also permits closer spacing between conductors than a traditional glass-to-metal seal, thus having more possible within a single space. Cost and lead time can also be a factor, as the time and effort to create the glass-to-metal seal can exceed those of a hermetic epoxy seal. To learn more about the differences between the technologies, read our whitepaper: Hermetic Seal Types

Can Douglas Electrical integrate connectors into my assembly?

Yes, Douglas Electrical Components can integrate connector plugs (male) and receptacles (female) into your assembly. This simplifies the process for our customers and ensures that we electrically test the entire assembly. Vendor-specific connectors, terminals, and sockets can be designed into the assembly directly at the bulkhead or at the end of a length of wire or cable. If the connector itself needs to be hermetic, Douglas Electrical utilizes our PotCon series to apply an epoxy potting treatment that fills the gaps in third-party hermetic connectors that cannot meet the leak test requirements of the applications. The connector can be integrated directly into the bulkhead fitting or we can create a cable harness with integral connectors.

What are the standard tests available for electrical feedthroughs? Douglas Electrical Components offers mechanical and electrical testing. Pressure leak tests through a bubble test can be performed on assemblies. Vacuum leak testing can certify that products meet the agreed upon specification. High Potential, known as Hipot, testing verifies the electrical performance of the feedthrough on each assembly.

Do you make custom hermetic electrical feedthroughs?

Yes. Most of our operation’s production is based upon made-to-order semi-custom and custom electrical feedthroughs. Our technical sales and application engineers partner with customers to find solutions for the end product. We combine many COTS (commercial-off-the-shelf) connectors and wires with our in-house machined components to manufacture cost-competitive solutions with a quick turnaround.

What is the difference between a cable feedthrough and a wire feedthrough?

Cable feedthroughs include the jacketed cable within the feedthrough housing and assembly whereas wire feedthroughs are traditionally individual conductors. Douglas Electrical can hermetically seal cables for power, signal, and fiber applications. We ensure the jacket of the cable is hermetically sealed within the epoxy feedthrough. Our epoxy can bond to or be prepared to bond to various cable jacket materials to create the hermetic seal required.

How many conductors can fit within a hermetic wire feedthrough?

This question is commonly asked in conjunction with wire density. There are various factors that determine how many conductors can fit within a single hermetic wire feedthrough. We need to understand parameters such as the wire gauge/thickness, number of conductors, and inside diameter of the feedthrough to ensure the proper flow of epoxy. Douglas Electrical will partners with customers to review these design factors to create a high-density hermetic feedthrough. Overall, a hermetic wire feedthrough can offer greater density than competing technologies such as glass-to-metal seals.

What is a wire bushing?

A wire bushing or line bushing is a type of wire feedthrough where the wire is sealed within a fitting such as a threaded conduit fitting. These terms are most common in the oil and gas industry. Douglas wire bushings are sealed wires and/or cables within a fitting to prevent the penetration of liquids or gases. Wire bushings are available with UL1203 Class I Division 1 Explosion proof ratings. Avoid the process of cementing wire fittings by using a pre-sealed line bushing in your application to transmit power or signal in hazardous locations.

Image Library

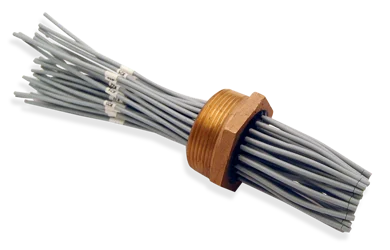

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

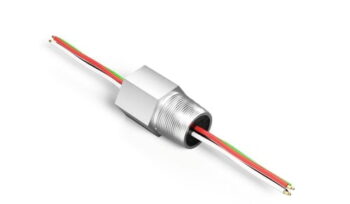

DuctorSeal Wire Feedthru

Multi-conductor hermetic wire feedthrough with NPT Threads

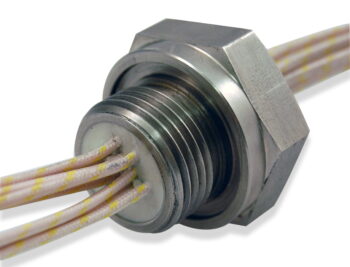

DuctorSeal Bulkhead Wire/Cable Feedthrough

DuctorSeal bulkhead wire feedthrough assembly with NPT fitting

5kV DC Hermetic Wire Feedthru

High voltage hermetic wire feedthrough for switchgear applications

Explosion-proof NPT Wire Bushing

Side view of Explosion-proof NPT wire bushing with standard aluminum housing

20kV 15nA DuctorSeal Hermetic Wire Feedthru

High Voltage 20kV 15nA DuctorSeal hermetic wire feedthrough

M12 Hermetic Cable Feedthrough

Hermetic NPT bulkhead feedthrough with M12 6-position connectors

Cryogenic Wire Feedthru

Cryogenic wire feedthrough with JIC fitting allows for operation in high pressure and low temperatures.

High Temperature Wire Feedthru

Threaded high temperature hermetic feedthrough with high temperature wire

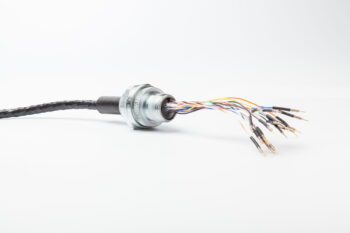

Explosion-proof Wire Bushing - Cable to Wire

Explosion-proof wire bushing seal; combine wires, cables, and connectors on either end of the bulkhead feedthrough fitting.

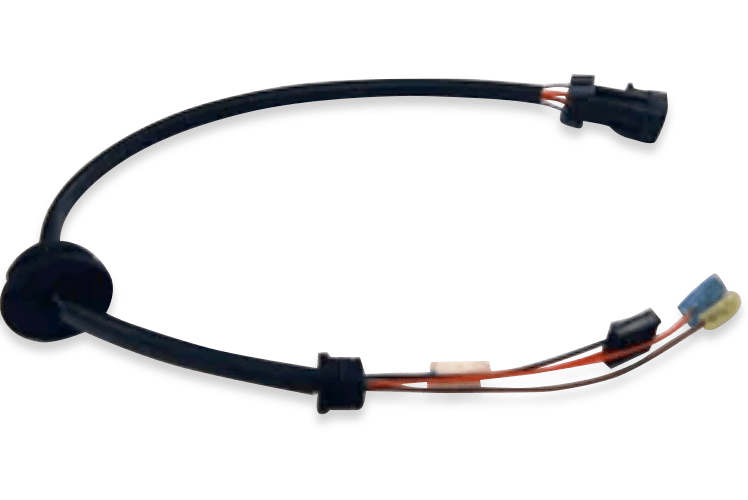

Electrical Feedthrough Harness

Customized electrical feedthrough with integral housing, wire, and electrical connection.

Explosion-proof Brass Wire Bushing

Female to male NPT bushing is hermetically sealed at the factory for direct install

Hermetic SAE Wire Feedthrough

Hermetically sealed wire assembly through SAE housing with integral connectors

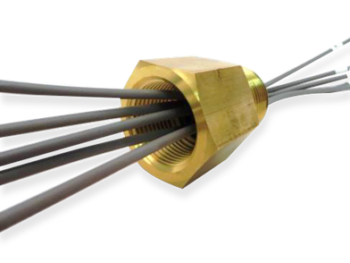

DuctorSeal high conductor count feedthrough

High conductor count DuctorSeal seals more than 1,000 conductors inside a single penetration. DuctorSeal hermetic wire feedthroughs support conductor densities that would be impossible with a traditional sealed connector.

Hermetic Coaxial Feedthrough

hermetic coaxial feedthrough with NPT threads and coaxial wires

DuctorSeal hermetic electrical flange assembly

50 Ohm, 75 Ohm and 100 Ohm impedance matched hermetic Quadrax and Spacewire solutions have become a common need for the Satellite industry.

Cable-to-wire Feedthrough

SAE threaded hermetic wire to cable feedthrough with integral cable shielding

ASME Wire Feedthrough

Hermetic wire feedthrough in custom explosion-proof ASME housing

Hermetic wire-to-cable feedthrough

Create hermetic electrical feedthroughs between wire and cable. This design features a simple O-ring flange.

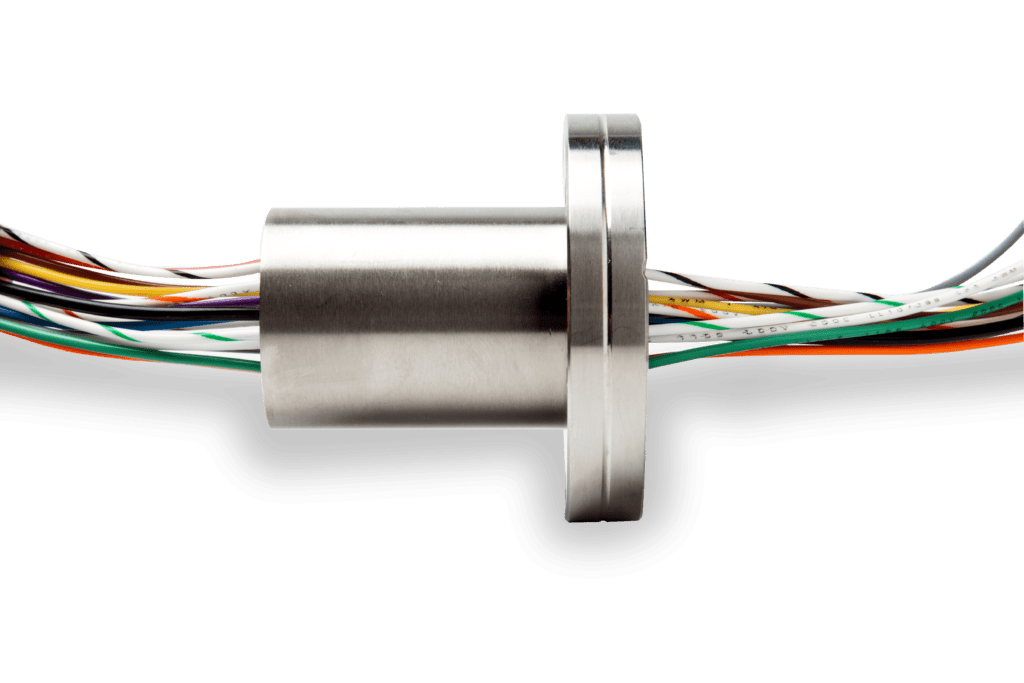

CF Feedthrough DuctorSeal

DuctorSeal CF flange hermetic wire feedthrough for vacuum applications.

Dual O-ring Wire Feedthru

Automotive hermetic feedthrough with double O-ring seal

explosion-proof wire bushing seal

Explosion-proof wire bushing seal; combine wires, cables, and connectors on either end of the bulkhead feedthrough fitting.

Turnkey Terminated NPT Cable Feedthrough.

Designed for plug-and-play application

DuctorSeal customized cable harness

DuctorSeal customized cable harness

Documents & Downloads

Literature

Whitepapers

Material Data

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations