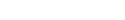

Explosion-proof wire bushing seal; combine wires, cables, and connectors on either end of the bulkhead feedthrough fitting.

Cable potting involves encasing conductors in an epoxy, liquid, or gel within an enclosure or feedthrough housing. Douglas Electrical Components employs a proprietary hermetic epoxy to seal wire and cable feedthroughs requiring cable potting. Cable potting is often done in-house by OEM’s or through some Douglas competitors. Differences can arise in the potting encapsulation compound, sealing approach to the conductors, and testing. It enhances protection, durability, and offers benefits like vibration resistance, electrical insulation, and thermal management.

Cable Potting Compound

Douglas employs a proprietary hermetic, moisture-tight epoxy when potting wires and cables to a feedthrough housing or within a connector assembly. The potting and encapsulation compound meet various standards across industries, from NASA ASTM E-595-93 (0.33% TML. 0.00% CVCM) to ATEX, IECEx, and Class I Division I explosion-proof/flame proof ratings for hazardous locations. Our epoxy material is proven to bond to various feedthrough housing materials including stainless steel, aluminum, titanium, and plastic and is rated for pressures from vacuum to positive pressure up to 15,000 PSI.

Threaded high temperature hermetic feedthrough with high temperature wire

Our epoxy also offers excellent liquid and gas compatibility, including submersion in various oils, fuels, and exposure to cryogenic liquids and gases.

Sealing Approach at Douglas

Douglas can offer two main sealing approaches to manufacturing a potted cable assembly. With JacketSeal, Douglas will seal the outer jacket of the feedthrough assembly. Our epoxy will seal to virtually any conductor jacket material including PTFE, PVDF, and ETFE.

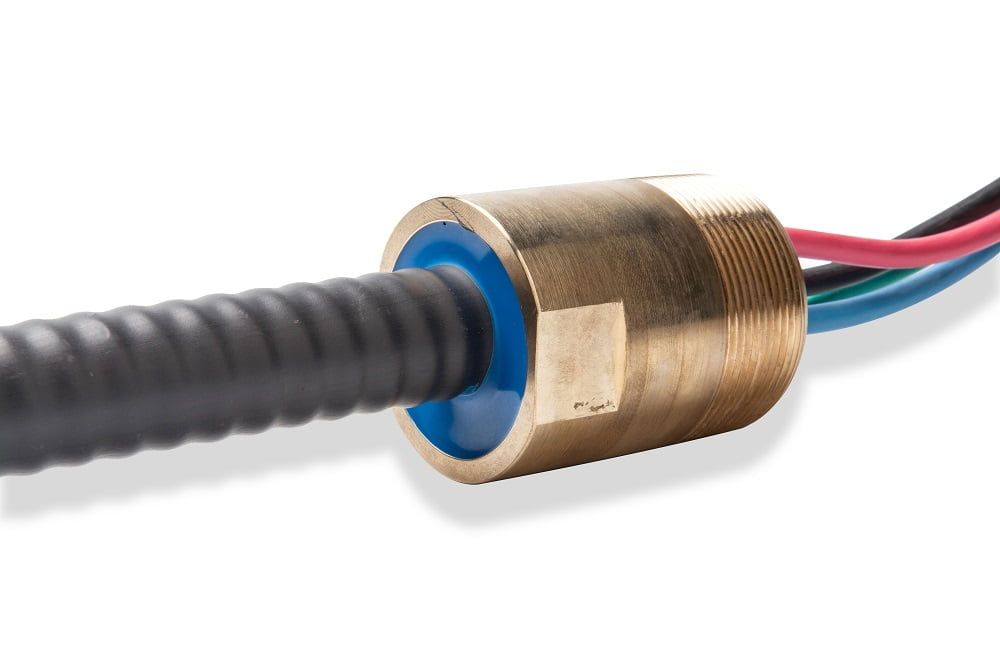

Second, Douglas can seal directly to the conductor or optical fiber within the wire jacket. Our DuctorSeal series allows us to create a true hermetic seal at the conductor level. DuctorSeal is used across various industries and applications where hermetics are required on the complete assembly.

Douglas has the design flexibility to incorporate different conductor types and sizes within the same feedthrough assembly. We offer complete customization of the design with minimal impact on lead time. Our cellular-based manufacturing is both equipped with the people and tooling to build high-quality customized potted cable assemblies designed specifically for the applications performance requirements and to simplify its utilization within your design.

Testing Excellence at Douglas

Summary

- Use proven hermetic epoxy material that can meet various standards including hazardous locations, various pressures, and exposure to various liquids and gases.

- Design the exact feedthrough you need, customizing the conductors, level of sealing, and integration of any requirements you have in a short lead time.

- Receive a fully electrically and mechanically tested assembly that is ready for installation.