Semiconductor Equipment

Highly reliable hermetic electrical feedthroughs for semiconductor equipment

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Distribution

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

Our longstanding experience with semiconductor processing machinery allows us to design, manufacture, and deliver high-performance hermetically sealed feedthroughs and engineered feedthrough subassemblies with the shortest lead times you’ll find anywhere. Speak to our experts and learn more about our hermetic wire seals, hermetic sealing epoxy, and our electric feedthrough connectors for the semiconductor industry. We offer solutions for power, signal, and fiber optic signal transmission in UHV environments. Our epoxy technology offers hermetic seals with low outgassing as well as a wide range of chemical compatibility for critical applications where contamination is a concern. Our technologies can be combined to offer complete assembly solutions requiring cables, power feedthroughs, wires (including thermocouples), and connectors; the combination can be in the form of a wire assembly or our Portplate multi-port flange assembly. Design the exact connection type that will enable a high reliability electrical connection for long-term use.

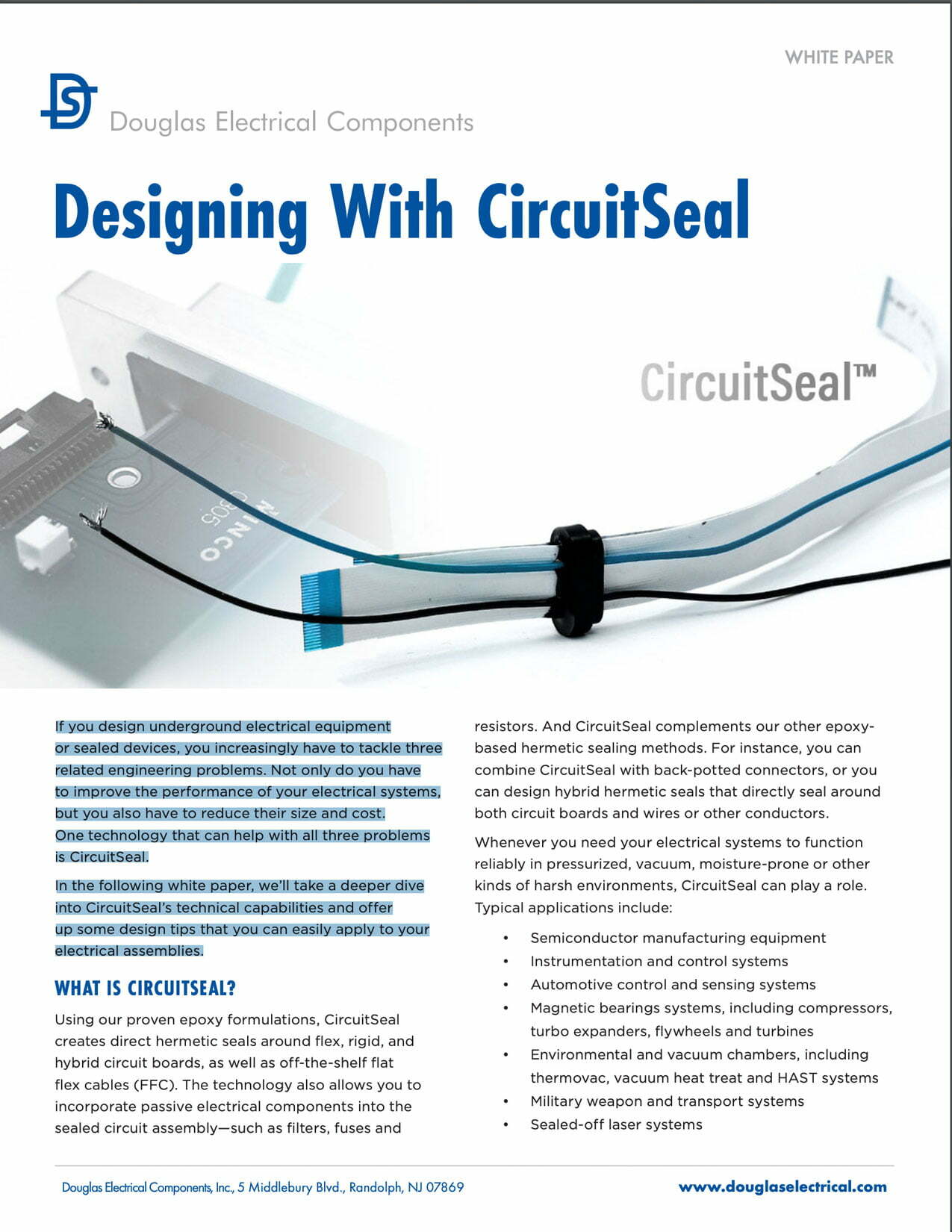

Our hermetic feedthroughs are utilized in various types of semiconductor equipment from vacuum chambers to wafer processing systems. Our epoxy technology creates high-density assemblies for OEM equipment designs. Douglas Electrical can hermetically seal power, signal and fiber connection points within the same assembly as well as fully-populated printed circuit boards.

Douglas Electrical Components has manufactured customized solutions over the past few decades for the semiconductor industry. For example, we manufacture sealed thermocouple and shielded cable feedthroughs to monitor temperature and critical process gases, sealed to high current studs to 750 amps. For wafer transfer drive and motor systems, Douglas offers sealed connector and cable assemblies to communicate low-level power and sensor signals through a single, compact penetration. Our low-outgassing hermetic seals are used in HIVAC containment for a beam mask writing tool.

Contact our engineers today for your semiconductor feedthrough requirements.

Semiconductor Solutions

Sealed Pogo pins for push/pull PCB mating

Sealed pogo-pins for push/pull PCB mating are custom designed for test and measurement applications.

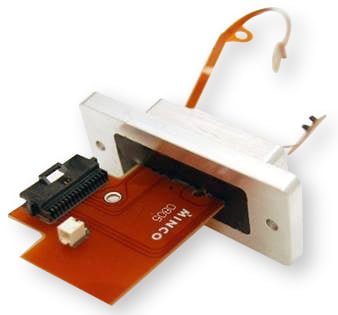

Pin to Flex assembly

CircuitSeal hermetic pin to flex assembly in custom housing

High Voltage Vacuum Feedthrough

High voltage vacuum feedthrough designs are available with integral wires and connectors.

Hermetic Coaxial Feedthrough with QF50 Flange

hermetic coaxial feedthrough with QF50 flange and four BNC connections

PotCon SMA hermetic feedthrough connector

PotCon SMA hermetic feedthrough connector with UNF thread. Select single connection feedthroughs or integrate into a larger plate assembly.

USB-C PotCon Hermetic Connector

USB-C hermetic connector in compact flange clamp mount design

PBTR Micro-D Combination Feedthrough

Combine multiple connectors into a single mechanical interface

15 position Hermetic Micro-D Reversible Hermetic Feedthrough

15 position Hermetic Micro-D reversible hermetic feedthrough front pin view

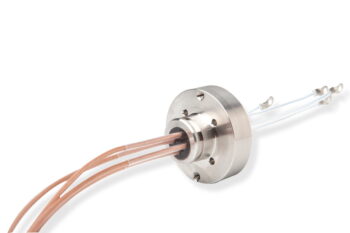

Micro-D Hermetic Portplate Assembly

Micro-D Hermetic assembly; customers can design multiple connectors within a PortPlate, custom design a solution, or choose a standard hermetic Micro-D feedthrough with reversible mounting

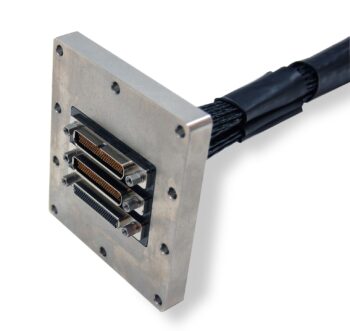

Micro-D hermetic feedthrough assembly

Micro-D hermetic feedthrough assembly with custom wire connection set up for drop-in installation.

Portplate Hermetic Assembly

Combine power and signal into a signal flange or plate

StudSeal Customized Feedthrough

Customized hermetic terminal seal material and mechanical interface

High Density Fiber Feedthru

Hermetic fiber optic cable seals designed into a high-density flange assembly. This design combines multimode and single-mode fibers in a CF flange.

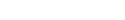

CF Feedthrough DuctorSeal

DuctorSeal CF flange hermetic wire feedthrough for vacuum applications.

Circuit Board Sealed Assembly

Rigid-flex CircuitSeals reliably seal complex electrical packages based on flex PCB connectors that combine flexible and rigid sealer substrates.

Hermetic USB to Micro-B Feedthru

Hermetic USB to Micro-B hermetic feedthrough with custom housing

Features

TECHNICAL ADVANTAGES

- High vacuum containment with low-outgassing epoxy (0.33% TML, 0.00% CVCM).

- Quick turnaround of hermetic feedthroughs, including those with complex cable harnesses and custom flange geometries

- One hundred percent leak tested with typical leakage rates less than 1×10-9 cc-He/sec

- Drop-in replacements for common feedthrough components

EXAMPLE APPLICATIONS

- Hermetically sealed feedthroughs bring multiple signal, power and air lines through a single vacuum chamber port to fully populated PCBs.

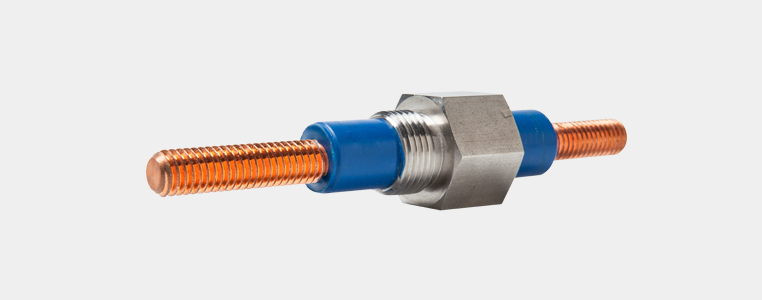

- High-current power connections for processing chambers using 750-amp StudSeal™ feedthroughs.

- Compact hermetic power and sensor seals for wafer transfer motor and drive systems.

- Single or multiple optical fiber feedthrough for optical detection of wafer cassette position in load lock.

- Pogo pin feed-through for quick and easy mating to contact pads on PCB. Connectorized wire side for quick and accurate installation.

- Heated paddle subassemblies and multi-cable vacuum penetrations.

- Fully tested turnkey sub-assemblies for wafer-processing equipment like ion etch tools, ion implant systems and in-line vacuum applications

SEMICONDUCTOR APPLICATIONS OPERATING IN A VACUUM ENVIRONMENT

- Deposition: Vacuum deposition is a process in which a thin film of material is deposited onto a substrate using a vacuum chamber. This process is used to add layers of materials to a semiconductor wafer during the fabrication of ICs.

- Etching: Vacuum etching is a process in which a material is selectively removed from a substrate using a chemical etchant and a vacuum chamber. This process is used to pattern the layers of materials on a semiconductor wafer during the fabrication of ICs.

- Ion implantation: Ion implantation is a process in which ions of a specific element are implanted into a substrate using a vacuum chamber. This process is used to modify the electrical properties of the substrate and is an important step in the fabrication of ICs.

- Thin film processing: Thin film processing is a group of vacuum processes that are used to deposit, etch, and pattern thin films of material on a substrate. These processes are used to fabricate a wide range of microelectronic devices, including ICs.

- Packaging: Vacuum packaging is a process in which a device or component is sealed in a vacuum-tight container to protect it from contamination and moisture. This process is often used to package semiconductor devices for storage and transportation.

Products

Documents

Literature

Datasheets

Whitepapers

Versatile Hermetic Epoxy Seals Protect Fiber Optic Cable and Ensure Signal Quality

PDF Catalog

PDF Catalog

Certificates & Standards

Related Products

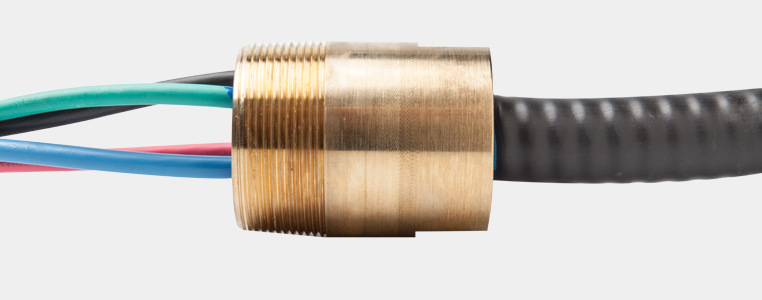

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

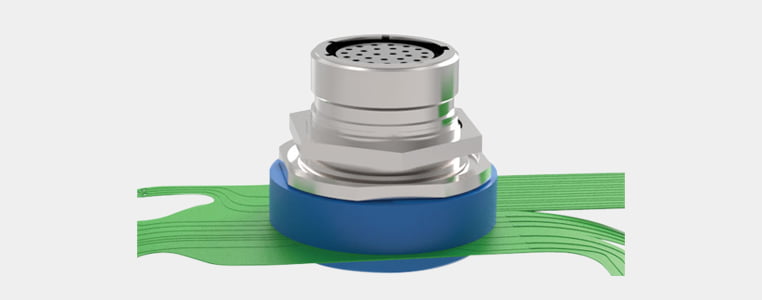

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of up to 1,000 amps and 15kV.

Custom Hermetic Flange & Plate Assemblies

Multi-port hermetic assemblies accommodate any feedthrough configuration, with time and troubleshooting minimized.

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

Coaxial Feedthroughs

Hermetically seal coaxial connections for vacuum and pressure applications.