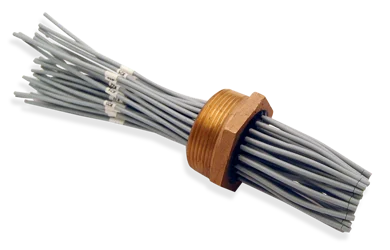

Seal tight connectors, also referred to as Sealtite connectors are electrical cable glands used in hazardous locations. Wire or cable passes through the center of the fitting with a locking nut that tightens to the outside diameter of the cable jacket. Various configurations are available, each with hazardous area ratings.

Seal tight connectors offer a degree of design flexibility compared to standard line bushings. Since the gland is installed in the field, technicians can adjust the cable length on each side of the fitting according to the specific requirements of the job site. This can help reduce wasted cable lengths.

Why consider a Line Bushing to replace a Seal Tight Connector?

-

- Line bushings offer greater or tighter sealing capabilities than seal tight connectors. Using high strength hermetic epoxy, Douglas Electrical Components can offer a complete hermetic seal directly to the conductor. This offers enhanced protection to both the cable’s outer jacket and the conductors within, which is particularly crucial in areas with hazardous gases and high humidity, ensuring system operation and safety.

-

- Line bushings offer greater performance in pressurized environments, including cryogenic systems. Douglas hermetically sealed line bushings where the mechanical housing is installed directly into the The epoxy combined with the housing acts as the primary seal, creating access to measure and monitor the pressurized equipment such as measuring temperature of a cryogenic tank. Seal tight connectors have lower pressure ratings and rely on the installer to seal and test the connection for electrical and mechanical performance.

-

- This leads to testing. Seal tight connectors installed in the field are more challenging to test. Douglas performs electrical (high pot) and mechanical (either helium leak test or pressure) 100% tests to ensure the assembly meets customer and approval agency requirements. IPC-620 certified technicians build and test assemblies to ensure they are plug-and-play ready for use.

-

- Designed for the OEM, line bushings can save time by integrating various design options into the assembly compared to seal tight connection. Douglas can include armor, shielding, and more with design for manufacturing top of mind.

-

- A wide range of approvals are available for Douglas line bushings, in particular UL Class I Division I explosion-proof, ATEX Ex-d Zone 0 and IECEx Exd Zone 0. These certifications allow for the installation of products in hazardous areas with the testing and markings to keep your system compliant and safe. Additionally, line bushings often have a higher rating to operate directly in the hazardous area compared to glands that require installation within Division 2 or Zone 2.

-

- Seal tight connectors use a continuous piece of cable within the gland compression seal. Jacketed cables including integral armor can be expensive. Epoxy offers design flexibility to combine two different conductor types. In this example, Douglas combines individual conductors within a brass housing that is mounted inside a panel. The outside cable is armored, with the armor also sealed within the epoxy. This makes for a simpler installation within the control panel, less wire prep in the field, and a decreased cost.

Both Seal tight connectors and line bushings each have their values. Douglas is here to support all your standard and custom line bushing requirements in hazardous and non-hazardous applications.