Underwater Connectors

Hermetic connector solutions for marine applications

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- D-sub Connectors

- Micro-D Connectors

- 38999 Connectors

- Coaxial Feedthroughs

- M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

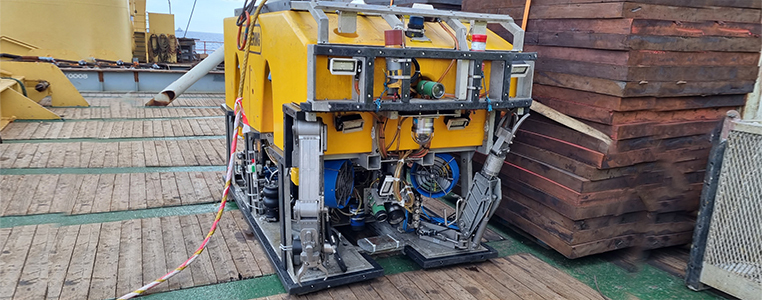

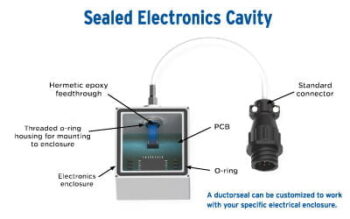

At Douglas Electrical Components, we specialize in designing hermetic sealed underwater connectors that cater to a range of applications. We understand the unique challenges faced in underwater environments. Whether it’s for marine applications, subsea connectors, or Remotely Operated Vehicle Systems (ROVs), having reliable subsea electrical connectors is crucial. That’s where our customized hermetic solutions for underwater connectors come into play.

Our epoxy technology is suitable both for depth pressures in underwater environments as well as pressurized and vacuum systems that are submerged. Understanding the differential pressure of the system is crucial, yet Douglas feedthroughs can be designed for pressures up to 1,000 bar. Feedthrough housings are completely customizable for underwater applications including both the housing material and the feedthrough connection method. This can include Aluminum, stainless steel, plastics, or specialty alloys such as Inconel or Titanium.

Our fully hermetic sealed underwater connectors ensure a watertight and corrosion-resistant connection, safeguarding the delicate electrical systems within ROVs. Our engineers understand the unique requirements and challenges faced by ROV operators, and offer customized connectors that precisely match your project’s specifications. We can incorporate various brands and types of connectors including wet pluggable connectors and fiber optic connectors into a hermetic assembly solution. Additionally, we can integrate various wires and cables within an assembly.

We specialize in the design and manufacture of custom hermetic feedthroughs, tailored specifically for ROVs. These feedthroughs are meticulously engineered to seal stabilizer systems under vacuum pressure, offering unparalleled protection against water ingress.

Our epoxy feedthroughs are trusted in a variety of naval applications. We produce lightweight, high-density feedthroughs integrating connectors, flex circuits, and more into a single feedthrough port. Additionally, optical fibers can be hermetically sealed for communication systems operating in underwater and subsea environments.

Underwater connections could include those applications that are flood-prone, such as underground switchgear and power distribution equipment. Douglas can protect cabinets and systems from water exposure to continue operation in the most critical environmental challenges such as storms.

Why Choose Douglas Electrical for Hermetic Sealed Underwater Electrical Connectors?

When it comes to Hermetic Sealed Underwater Connector services for ROVs, Douglas Electrical is your trusted partner. We prioritize the safety of your ROV and the success of your missions by delivering dependable hermetic sealing solutions. Our team of experts works closely with you to design and manufacture connectors that align perfectly with your specifications.

Contact us today to discuss your specific requirements and explore how we can enhance the performance and safety of your ROV operations.

Features

FEATURES

- Ability to withstand high pressures including depth or pressurized systems

- Customizable housing materials (stainless steel, aluminum, nickel alloys, Titanium, plastic, etc.)

- Seal directly to various conductor types including wires, pins, flex circuits, and more

- Increase feedthrough density thus reducing connection points

- Specify various subsea connector types integral to your feedthrough

Applications

- ROV’s

- UUV’s

- Fuel pumps

- Munitions

- Optics & Sensing

- Hydraulic systems

- Communication devices

- Towed Arrays

- Offshore platforms (explosion-proof)

FAQ

What are underwater connectors?

Underwater connectors are specialized electrical components designed to establish and maintain reliable electrical connections in underwater environments. They play a critical role in underwater technologies, such as Remotely Operated Vehicles (ROVs), submarines connectors, marine sensors, and offshore oil and gas equipment, where maintaining a reliable electrical connection in challenging underwater conditions is essential for safe and efficient operations.

What are hermetically sealed underwater connectors?

A hermetic seal is any seal that prevents the ingress of both gasses and liquids. In this case, a hermetically sealed underwater connector is any connector designed for underwater use, that completely isolates the connection point from outside liquids and gasses, usually trapping a small amount of gas around the connection inside the seal. This kind of connection provides an incredibly stable and reliable environment around the connection point, minimizing potential variables and points of failure for more consistent performance under pressure.

Why is it important to use sealed underwater connectors?

Sealed underwater connectors are crucial as they prevent water damage to sensitive equipment, ensuring reliable electrical connections. Additionally, in hydraulic systems, the hermetic underwater feedthrough can be used to transmit signals from within a pressurized chamber or system to monitor function. This reliability is essential for the safe operation of underwater technology and protecting the marine environment from potential contamination.

How much pressure can underwater connectors handle?

The pressure-handling capacity of underwater connectors varies widely, from around 1,000-2,000 psi for shallow waters to 5,000 psi or more for deep-sea, subsea, or pressure-balancing applications. Choosing the right connector depends on the specific depth and pressure conditions of the application.

What sets Douglas Electrical apart as a provider of hermetic sealed underwater connectors?

We have a dedicated team of experts who understand the specific challenges faced by ROV operators and and mechanical engineers to prioritize safety and mission success. Our commitment to delivering dependable hermetic sealing solutions and offering customized connectors makes us a trusted partner.

Can Douglas integrate a wet-pluggable connector?

Yes. Douglas partners with various manufacturers to source high-quality wet-pluggable connectors to integrate into feedthroughs. Our IPC-620 technicians will carefully seal directly to the conductors to ensure a true hermetic seal.

Image Library

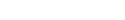

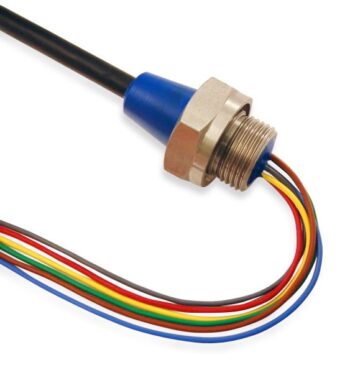

JacketSeal Connector to wire Assembly

JacketSeal waterproof and weather proof wire/cable connector assembly

Water-tight cable assembly with jamnut

Water-tight cable assembly with jamnut

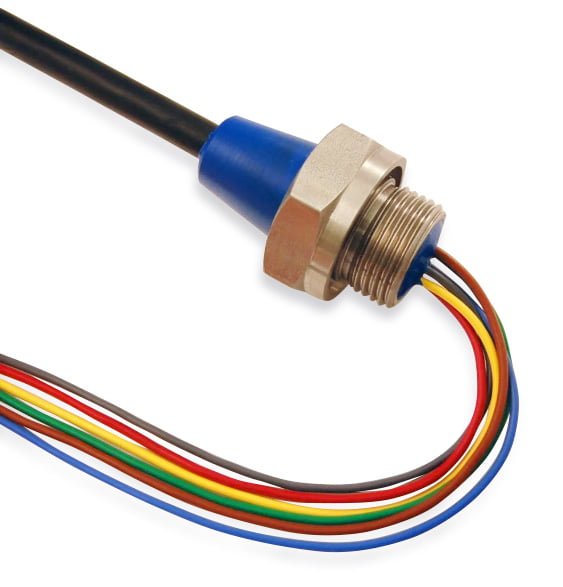

Waterproof Push-Pull Connector Assembly

Waterproof connector assembly; seal non-hermetic connectors in cost effective packages with Douglas JacketSeal.

Water-tight Fiber Assembly

Water-tight sealed fiber optic cable assembly

Waterproof PotCon connector

Sealed circular metric connectors available with integral wires cut to length.

Water-proof Cable Assembly

Water-proof cable assemblies available with custom integral connection options to retrofit existing wiring or meet new requirements.

Sealed MIL-spec Connector Harness

Customer-specific design with moisture-tight sealed connector ends

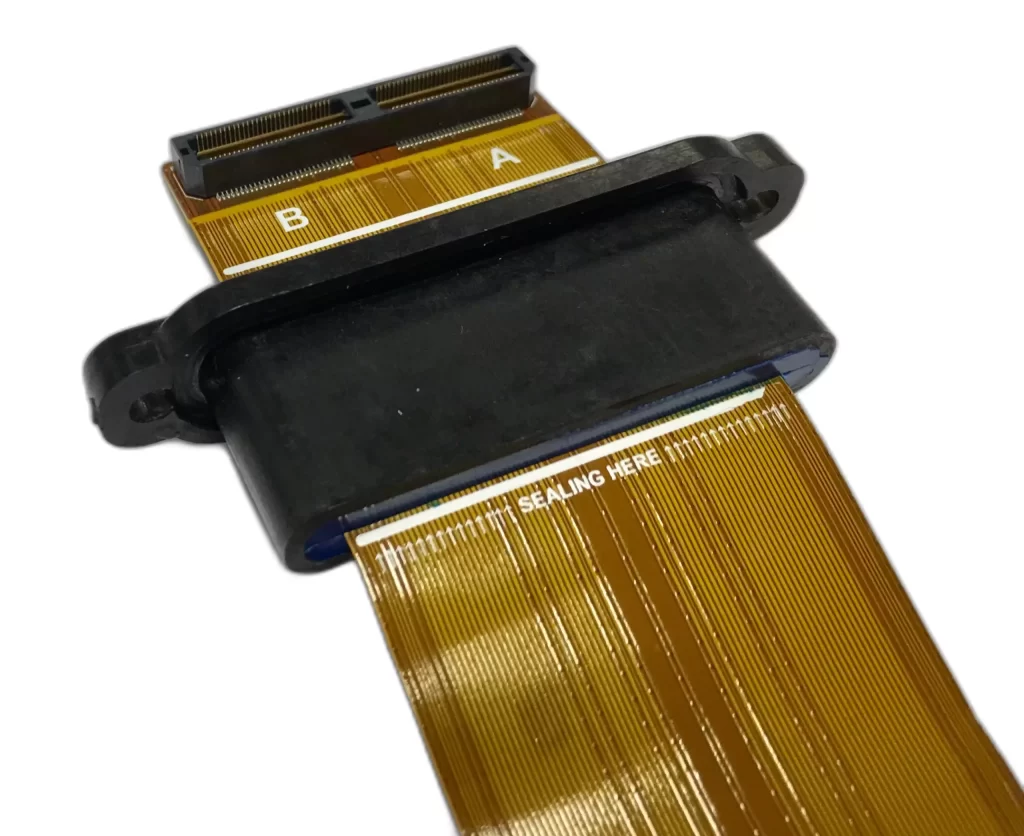

NPT Explosion-proof Cable Assembly

Explosion-proof conduit seal with NPT threads can be designed for hazardous locations including explosion-proof environments.

Hermetic USB to Micro-B Feedthru

Hermetic USB to Micro-B hermetic feedthrough with custom housing

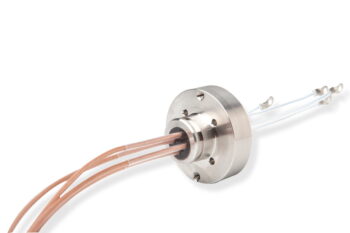

Fiber Optic Radial O-ring Feedthru

High pressure fiber optic feedthrough with radial O-ring design

Portplate rectangular, wire feedthrough

Hermetically Sealed Plastic Connector

customized plastic connector with integral pins for pressure application

Hermetic bulkhead fiber optic feedthrough

Fiber Optic connector and cable integrated into a bulkhead assembly

PBTW Custom Flange connector to wire feedthru

MIL-spec hermetic connector with custom rectangular flange and integral wires

Radial O-ring wire feedthrough

High density wire feedthroughs for high pressures and volumes.

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

High Voltage Vacuum Feedthrough

High voltage vacuum feedthrough designs are available with integral wires and connectors.

High Pressure Hermetic Connector Feedthrough - 5015

High Pressure Hermetic Connector Feedthrough using a 5015 interface. Customize the connector and fittings as well as how you connect within the vacuum or pressure environment.

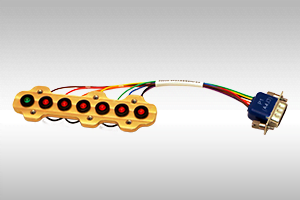

Custom LED hermetic wire harness assembly

Custom LED hermetic wire harness assembly

Custom StudSeal

Custom material housing with integral hermetic stud terminations

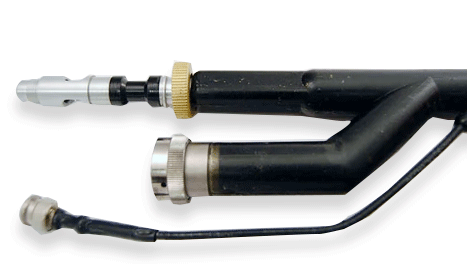

Pin to Flex assembly

CircuitSeal hermetic pin to flex assembly in custom housing

Hermetic Control Box Assembly

Hermetically sealed housing from circuit board to wire assembly. This assembly creates a plug-and-play electrical connection that is hermetically sealed and saves installation time. This is a common configuration in IoT devices.