Wire & Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough

using virtually any conductor

Product Categories

-

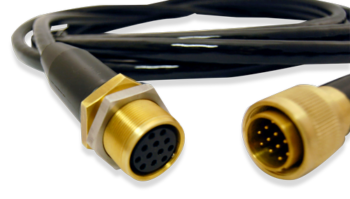

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

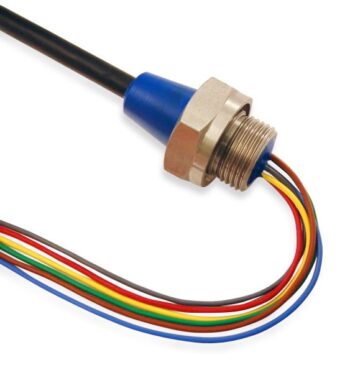

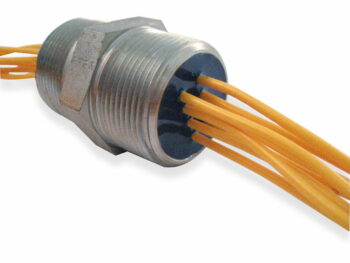

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

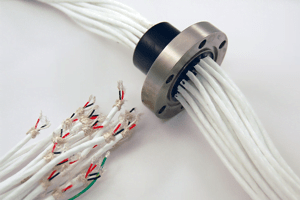

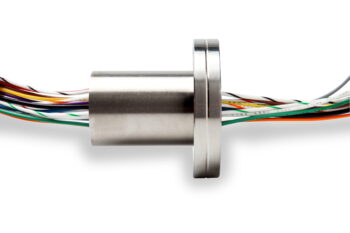

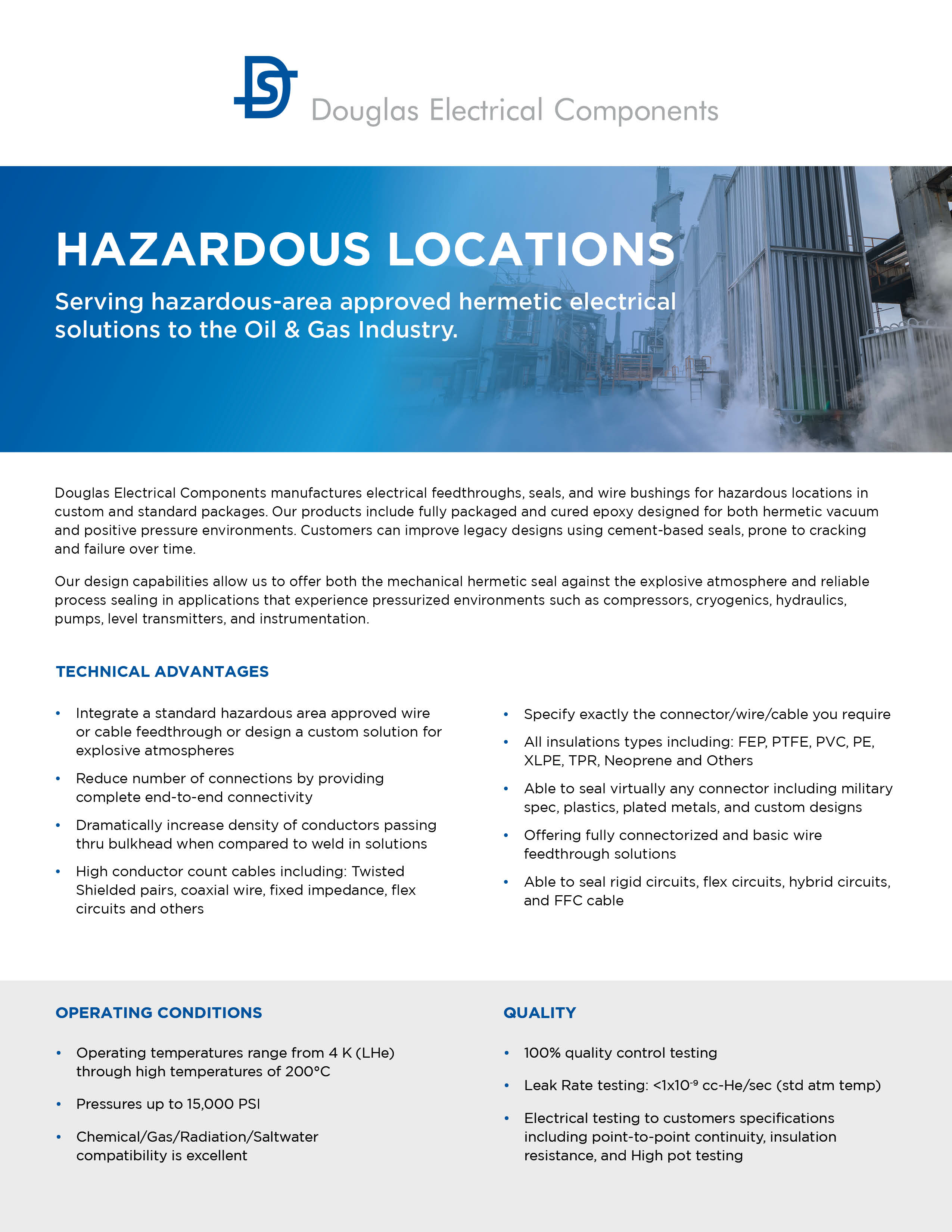

Douglas Electrical Components offers the unique ability to manufacture hermetic and non-hermetic, high-density wire and cable feedthroughs for a variety of applications and industries. From aerospace applications to hazardous locations, Douglas wire and cable feedthroughs and assemblies are trusted to survive harsh environments and conditions.

Using a high-strength epoxy, Douglas Electrical creates hermetically sealed feedthroughs that protect equipment, controls, and instrumentation from various liquids and gases. Our epoxy will hermetically seal to virtually any conductor or optical fiber on the market, creating a virtually unlimited combination of options for gauge, material, length, and connection types.

Wire and cable feedthroughs are also available with various value added services. Douglas can create the harnessing, shielding, connectorization, and labeling to seamlessly integrate into your system in various production volumes. Our IPC-620 certified technicians are highly skilled and trained in supporting complex harnesses and feedthroughs across a variety of industries.

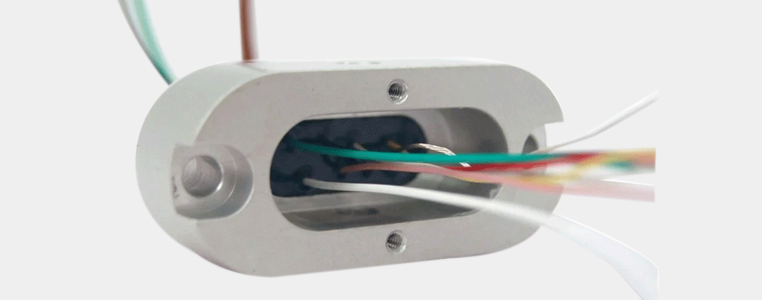

The feedthrough housing is available in various configurations and materials to meet environmental conditions like pressure and temperature as well as design for manufacturability; this can include using a customer-supplied housing. We offer in-house CNC machining services for housings to ensure quality and competitive pricing.

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Liquid Tight Wire / Cable Feedthrough Seals

Create a high-density, sealed wire or cable electrical feedthrough

for use in hazardous and/or non-hazardous areas.

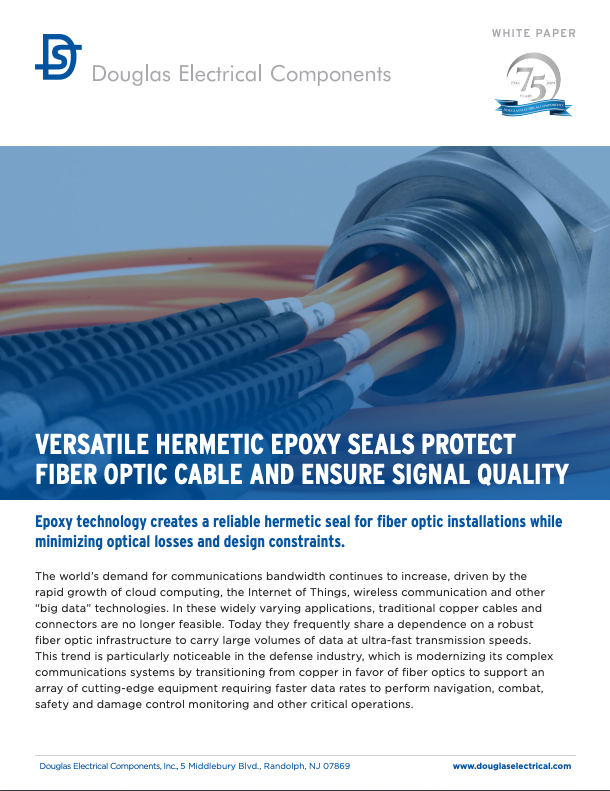

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

Cable Harnesses

Wire and cable harnesses designed and manufactured to your specific requirements.

Why Choose Douglas Wire & Cable Solutions?

- Work with any type of wire or cable. We are not limited by insulation or conductor material, size, shielding, or other variables. Numerous options include discrete wires, multi-conductor cables, coaxial or even Quadrax cables, ribbon cables, flex and other circuit board assemblies.

- Specify any conductor type, any length preferences, and any terminations required (pigtails, terminals, contacts, connectors, etc.). Whether the design calls for 8AWG PVC wires, flat flex circuit (FFC), or 24AWG Teflon twisted, shielded pairs to be sealed, we’ve got it covered.

- Mix & match conductor types: For instance, one feedthrough can contain copper wires, optical fiber cables, thermocouples, power cables, twisted shielded pairs, and others of varying AWG in any combination.

- Cable-based feedthroughs allow us to maximize conductor density. Douglas can fit significantly more conductors through a given feedthrough size compared to a connector-based feedthroughs.

- Thermocouple and signal harnesses offer end to end, uninterrupted continuity for the most accurate signal integrity. Minimizing connection points means less voltage drops and contact resistance issues, and better overall performance.

- All designs can be partially or entirely customized with support from our experienced applications and sales engineering staff to best fit your technical and cost requirements.

- Our epoxy-based sealing technology covers a wide variety of temperature ranges, extensive pressure differentials, and is chemically compatible with most all substances, from refrigerants to get fuels, that our customers look to seal.

Features

WIRE FEEDTHROUGH PERFORMANCE CAPABILITIES

- Uses the same wire and insulation types already approved for use elsewhere in your system

- <1×10-9 cc/sec per feedthrough

- Pressures of 15,000 psi

- Operating temperatures range from 4 K (LHe) through high temperatures of 200°C

- High-voltage cables up to 30,000 V

- Full cable harness options with connectorization available

- Wire gauges from 38 AWG to 500 MCM

- Conductor counts from single wire to 3,200 in a single feedthrough

- Cable lengths from stubs to 2,000 meters

- NASA’s ASTM E-595 low outgassing specification with just 0.26% weight loss and less than 0.002% VCM.

COMMON HOUSING TYPES

- NPT

- Face seals

- Radial O-rings

- SAE

- CF/QF/KF flange

- ANSI flange

- Custom options available

COMMON WIRE & CABLE TYPES

- Individual wires (PTFE, PVC, etc.)

- Jacketed cable

- Coaxial feedthroughs

- Thermocouple

- Customized assemblies with integral connectors

- Visit our OptiSeal page for Fiber Optic Feedthroughs

MARKET CAPABILITIES

- ISO 9001:2015

- ISO 14001:2015

- ITAR DDTC Registration

- UL/cUL 1203, UL 886, UL 674, and UL 913

Featured Products

Wire & Cable Feedthroughs Configurations

View our standard Wire & Cable Feedthroughs configurations. For further customization, our team is ready to help tailor products to meet your needs.

| Product Name | Housing Material | Housing Size | Housing Type | Wire Type | Wire Gauge | Conductor Count | Vacuum Leak | Electrical Hipot | Pressure Limit* |

|---|---|---|---|---|---|---|---|---|---|

| 28103 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2500 PSI |

| 28050 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28102 – 10 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 10 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28049 – 10 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 10 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28064 – 5 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 5 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28012 – 5 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 5 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28100 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28078 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28063 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28054 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Nipple | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28047 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28026 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28011 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28002 – 2 Conductor Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Plug | Thermocouple Teflon® Insulation | 24 AWG | 2 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28099 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28046 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28077 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28025 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 12 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28095 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28094 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28075 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28042 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28023 – 12 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 16 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28020 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 3/4″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28088 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28059 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28036 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28007 – 6 Conductor Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28085 – 20 Conductor Hermetic Wire Feedthroughs | Brass | 1″ | NPT Nipple | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 20 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28032 – 12 Position Hermetic Wire Feedthroughs | Brass | 1″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 12 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28055 – 3 Position Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 3 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28052 – 3 Position Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 3 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28003 – 3 Position Hermetic Wire Feedthroughs | Brass | 1/2″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 3 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 28001 – 6 Position Hermetic Wire Feedthroughs | Brass | 3/8″ | NPT Plug | Stranded MIL-spec 1000V PTFE Insulated | 24 AWG | 6 | <1 x 10-6cc He/sec. Contact factory for more options. | 1000 VAC | 2,500 PSI |

| 29298 – 32 Position Conflat Hermetic Wire Feedthroughs | Stainless Steel | 2.75″ | Conflat flange | Stranded MIL-spec 1000V PTFE Insulated | 20 AWG | 32 | <1 x 10-8cc He/sec. Contact factory for more options. | 1000 VAC | - |

| 28023 Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 16 AWG | 12 | - | 1000VAC | - |

| 28321 Hermetic Wire Feedthrough | Stainless Steel | 1”-20 | Vacuum face seal with Nitrile O-ring | - | 20 AWG | 3 | - | 1000VAC | - |

| 28043 Hermetic Wire Feedthrough | Brass | 1″ | NPT Nipple | - | 16 AWG | 20 | - | 1000VAC | - |

| 28081T Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 24 AWG | 12 | - | 150VAC | - |

| 28110 Hermetic Wire Feedthrough | Brass | 1/2″ | NPT Nipple | - | 16 AWG | 3 | - | 1000VAC | |

| 28174 Hermetic Wire Feedthrough | Stainless Steel | 1/16″ | SAE | - | 20 AWG | 12 | - | 1000VAC | - |

| 28335J Hermetic Wire Feedthrough | Stainless Steel | 1”-20 | Vacuum face seal with Nitrile O-ring | - | 24 AWG | 10 | - | 150VAC | - |

| 28165K Hermetic Wire Feedthrough | Stainless Steel | 3/4″ | SAE | - | 24 AWG | 2 | - | 150VAC | - |

| 28353 Hermetic Wire Feedthrough | Stainless Steel | 1 1/4”-18 | Vacuum face seal with Nitrile O-ring | - | 16 AWG | 32 | - | 1000VAC | - |

| 28071 Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 20 AWG | 12 | - | 1000VAC | - |

| 28184T Hermetic Wire Feedthrough | Stainless Steel | 1 1/16” | SAE | - | 24 AWG | 20 | - | 150VAC | - |

| 28010 Hermetic Wire Feedthrough | Brass | 1/2″ | NPT Nipple | 12 AWG | 3 | 1000VAC | - | ||

| 28186 Hermetic Wire Feedthrough | Stainless Steel | 1/2”-20 | Vacuum face seal with Nitrile O-ring | 24 AWG | 6 | 1000VAC | |||

| 28160 Hermetic Wire Feedthrough | Stainless Steel | 3/4″ | SAE | - | 24 AWG | 12 | - | 1000VAC | - |

| 28068 Hermetic Wire Feedthrough | Brass | 3/4″ | NPT Nipple | - | 24 AWG | 20 | - | 1000VAC | - |

| 28163/6/4 Hermetic Wire Feedthrough | Stainless Steel | 3/4” | SAE | - | 12 AWG | 3 | - | 1000VAC | - |

FAQ

What is a hermetic feedthrough?

Hermetic is defined as any enclosure that prevents gasses and liquids (fluids) from migrating across the bulkhead. A common industry leakage rate is <1×10-8 cc-Helium/second. An hermetic electrical feedthrough will need to limit leakage from one side (vacuum pressure) to the other (atmospheric). Douglas customizes feedthroughs using a hermetic epoxy to seal within the bulkhead between pressure/vacuum and atmosphere..

What is a hermetic wire feedthrough?

A hermetic wire feedthrough is a type of electrical connector that is used to transmit electrical signals or power through a hermetic seal. A hermetic seal is a barrier that prevents the exchange of gases or liquids between the inside and outside of an enclosure, and is often used to protect components or devices from external factors such as moisture, dust, or contamination.

Hermetic wire feedthrough offers superior performance compared to electrical connectors. They have lower electrical losses, with connectors having voltage drops over 1 mV per crimp and 100 mΩ contact resistance, which can affect signal integrity.

What is a vacuum feedthrough?

A vacuum feedthrough is a more specific type of hermetic feedthrough. The bulkhead fitting is sealed and tested to ensure a hermetic seal between the vacuum pressure side of the feedthrough and the atmospheric side. Vacuum feedthroughs are common in vacuum systems, semiconductor equipment, gloveboxes, and space simulation systems. As more systems integrate instrumentation and sensors directly into the testing environment, electrical feedthroughs need to maintain the vacuum pressure environment. Vacuum feedthroughs typically integrate vacuum flanges such as CF flanges or KF flanges. These mechanical interfaces are offered in standard sizes that integrate into industry systems that often come with pre-populated ports. Other fittings are also possible including radial O-ring seals, which offer a smaller footprint.

Does Douglas Electrical Components manufacture wire or cable?

No. We have a trusted supply chain network that supplies us wire and cables. Additionally, we will partner with customers to specify the exact cable with new vendors as needed. We utilized IPC-620 technicians to manufacture the assembly as specified.

What are the advantages of an epoxy-based seal over a glass-to-metal seal?

Epoxy based seals allow more flexibility in design. Conductors can pass directly through the epoxy, allowing a simpler assembly process. Epoxy also permits closer spacing between conductors than a traditional glass-to-metal seal, thus having more possible within a single space. Cost and lead time can also be a factor, as the time and effort to create the glass-to-metal seal can exceed those of a hermetic epoxy seal. To learn more about the differences between the technologies, read our whitepaper: Hermetic Seal Types

Can Douglas Electrical integrate connectors into my assembly?

Yes, Douglas Electrical Components can integrate connector plugs (male) and receptacles (female) into your assembly. This simplifies the process for our customers and ensures that we electrically test the entire assembly. Vendor-specific connectors, terminals, and sockets can be designed into the assembly. If the connector itself needs to be hermetic, Douglas Electrical utilizes our PotCon series to apply an epoxy potting treatment that fills the gaps in third-party hermetic connectors that cannot meet the leak test requirements of the applications. The connector can be integrated directly into the bulkhead fitting or we can create a cable harness with integral connectors.

What are the standard tests available for electrical feedthroughs?

Douglas Electrical Components offers mechanical and electrical testing. Pressure leak tests through a bubble test can be performed on assemblies. Vacuum leak testing can certify that products meet the agreed upon specification. High Potential, known as Hipot, testing verifies the electrical performance of the feedthrough on each assembly.

Do you make custom hermetic electrical feedthroughs?

Yes. Most of our operation’s production is based upon made-to-order semi-custom and custom electrical feedthroughs. Our technical sales and application engineers partner with customers to find solutions for the end product. We combine many COTS (commercial-off-the-shelf) connectors and wires with our in-house machined components to manufacture cost-competitive solutions with a quick turnaround.

What is the difference between a cable feedthrough and a wire feedthrough?

Cable feedthroughs include the jacketed cable within the feedthrough housing and assembly whereas wire feedthroughs are traditionally individual conductors. Douglas Electrical can hermetically seal cables for power, signal, and fiber applications. We ensure the jacket of the cable is hermetically sealed within the epoxy feedthrough. Our epoxy can bond to or be prepared to bond to various cable jacket materials to create the hermetic seal required.

How many conductors can fit within a hermetic wire feedthrough?

This question is commonly asked in conjunction with wire density. There are various factors that determine how many conductors can fit within a single hermetic wire feedthrough. We need to understand parameters such as the wire gauge/thickness, number of conductors, and inside diameter of the feedthrough to ensure the proper flow of epoxy. Douglas Electrical will partners with customers to review these design factors to create a high-density hermetic feedthrough. Overall, a hermetic wire feedthrough can offer greater density than competing technologies such as glass-to-metal seals.

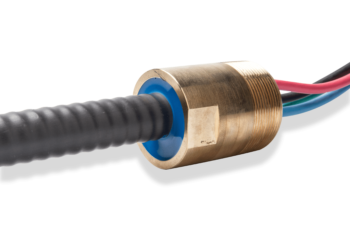

What is a wire bushing?

A wire bushing or line bushing is a type of wire feedthrough where the wire is sealed within a fitting such as a threaded conduit fitting. These terms are most common in the oil and gas industry. Douglas wire bushings are hermetically sealed wires and/or cables within a fitting to prevent the penetration of liquids or gases.

How do wire feedthroughs reduce costs compared to bulkhead connectors?

Wire feedthroughs can significantly reduce costs compared to bulkhead connectors. A single wire feedthrough often replaces multiple connectors, cutting design and assembly expenses. It simplifies supply chains and avoids over-specification costs.

Image Library

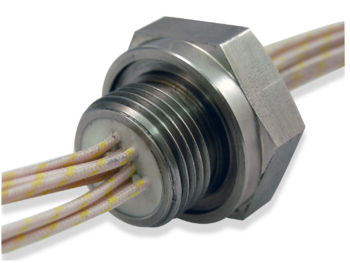

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

Explosion-proof Brass Wire Bushing

Explosion-proof Brass Wire Bushing design in female-to-male configuration. Avoid cement sealing wire bushings in the field by using an explosion-proof rated assembly sealed and tested at Douglas Electrical.

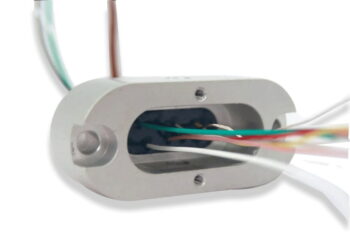

Explosion-proof conduit seal with cable to wire

Create explosion-proof wire bushing assemblies that integrate cables, wires, armor, and more.

High Density Conduit Assembly

DuctorSeal bulkhead wire feedthrough assembly with NPT fitting

CF Feedthrough DuctorSeal

DuctorSeal CF flange hermetic wire feedthrough for vacuum applications.

Custom High Voltage Feedthru

Hermetic wire feedthrough with radial O-ring seal

Hermetic Cable Assembly

Automotive hermetic assembly with integral cables, radial O-ring seal, and connectors

Sealed Feedthrough Assembly

Hybrid JacketSeal-DuctorSeal feedthroughs are used in applications requiring both true hermetic sealing and fluid blocking—such as this hybrid feedthrough that seals both the vacuum chamber and heat transfer fluid for a magnetic bearing flywheel.

High Temperature Feedthru Capabilities

Design feedthroughs with high temperature wires.

5kV DC Hermetic Wire Feedthru

High voltage hermetic wire feedthrough for switchgear applications

Radial O-ring wire feedthrough

High density wire feedthroughs for high pressures and volumes.

Custom Wire Feedthru

Custom feedthrough used in dental X-ray equipment

DuctorSeal high conductor count feedthrough

DuctorSeal high conductor count feedthrough. Create high-density electrical feedthroughs in less space than traditional electrical feedthroughs.

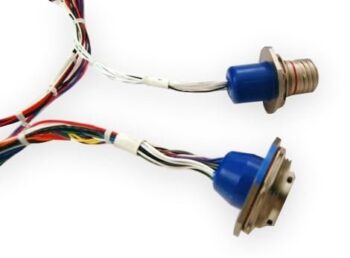

PotCon CF Hermetic Feedthrough

RBTW hermetic connector to thermocouple wire feedthrough with CF flange

Hermetic Terminal Seal with stud to wire assembly

Hermetic Terminal Seal with stud to wire assembly

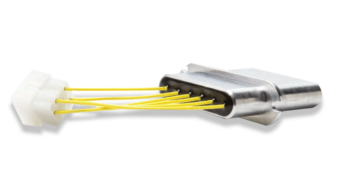

PBTW Custom Flange connector to wire feedthru

MIL-spec hermetic connector with custom rectangular flange and integral wires

Hermetic 38999 Wire Assembly

Hermetic MIL-DTL-38999 connector to wire assembly with O-ring seal rear view

Custom LED hermetic wire harness assembly

DFM assembly simplifies installation while improving reliability.

ASME Wire Feedthrough

Hermetic wire feedthrough in custom explosion-proof ASME housing

Hermetic M12 Feedthrough with NPT Bulkhead Mounting

Connectorized 6 Position M12 hermetic cable assembly designed for NPT bulkhead mounting

JacketSeal Custom Flanged Feedthrough

Small gauge wires sealed in custom flange assembly

Fiber Optic 38999 Connector

Integral optic fiber wire assembly with backpotted 38999 connector for plug-and-play use

SAE threaded hermetic wire to cable feedthrough

SAE threaded hermetic wire to cable feedthrough. Use braided cable assemblies to protect against harsh environments while mounting wires or fibers on the opposite side of the bulkhead.

Explosion-proof wire bushing seal

Explosion-proof wire bushing seal; combine wires, cables, and connectors on either end of the bulkhead feedthrough fitting.

Hermetic bulkhead fiber optic feedthrough

Fiber Optic connector and cable integrated into a bulkhead assembly

20kV 15nA DuctorSeal Hermetic Wire Feedthru

High Voltage 20kV 15nA DuctorSeal hermetic wire feedthrough

Integral Harness Backpotting Solutions

Create hermetic connector assemblies directly within your wire or cable harness assemblies

Quadrax and Spacewire Hermetic Solutions

50 Ohm, 75 Ohm and 100 Ohm impedance matched hermetic Quadrax and Spacewire solutions have become a common need for the Satellite industry.

Glovebox Convenience Cable Feedthrough

Glovebox Convenience Cable Feedthrough creates a wired connection to power equipment in Glove boxes and test setups. The cable allows for flexibility to reach the equipment in the glovebox without added extension cords or compromising space.

Hermetic cable to wire feedthrough

Create hermetic electrical feedthroughs between wire and cable

Oil and Gas Power NPT Feedthrough

Designed with larger gauge wire for power transmission

PotCon Pogo-pin Assembly

Hermetic bulkhead connector assembly with integral wires and pogo-pins

watertight wire harness with jamnut

Water-tight cable assembly with jamnut

NPT Feedthroughs

NPT Feedthroughs, also referred to as wire bushings, are available in various conductor sizes, counts, and configurations for hazardous and non-hazardous applications.

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Mil-spec Hermetic Feedthrough Assembly

mil-spec hermetic feedthrough assembly with integral connectors and mating cable assemblies

Sealed Vacuum Fiber Optic Feedthrough

OptiSeal Fiber Optic feedthroughs can be provided in cable or connector-based styles.

Hermetic feedthrough assembly with integral MIL-spec cable harness

hermetic feedthrough assembly with integral MIL-spec cable harness

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

High Density Fiber Feedthru

Hermetic fiber optic cable seals designed into a high-density flange assembly. This design combines multimode and single-mode fibers in a CF flange.

Documents & Downloads

Literature

Whitepapers

Versatile Hermetic Epoxy Seals Protect Fiber Optic Cable and Ensure Signal Quality

Material Data

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations