Hermetic Power Feedthroughs

Enabling Reliable Sealing Solutions for Vacuum and Pressure Applications

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

Douglas Electrical Components designs and manufactures hermetic power feedthroughs, offering reliable sealing solutions for a wide range of vacuum and pressure applications. We can also design power feedthroughs to handle high currents and voltages. Focusing on motors, compressors, and chambers, Douglas has established itself as a trusted partner for industries requiring robust and leak-free electrical connections in demanding environments.

Why Choose Douglas Electrical Components for Your Hermetic High-Power Feedthroughs

We take pride in our expertise and experience in design and development of hermetic high- current feedthroughs. The following factors have contributed to our success.

- Hermetic Sealing Excellence: At Douglas Electrical Components, we understand the critical importance of maintaining hermetic integrity in vacuum and pressure systems. Our hermetic power feedthroughs are engineered and manufactured to deliver exceptional sealing performance, ensuring a reliable and durable connection. By employing cutting-edge hermetic epoxy and adhering to stringent quality standards, we offer solutions that can withstand the most challenging operating conditions.

- Versatile Applications: Our hermetic power feedthroughs are used in various industries where vacuum and pressure sealing are vital. Whether it is in motors, compressors, or chambers, Douglas’ power feedthrough and motor terminal sealing solutions are designed to meet the unique requirements of each application. Our comprehensive product portfolio caters to diverse power and signal needs, making us the go-to choice for customers seeking reliable high-power feedthroughs and other electrical connections in critical systems.

- Motor Applications: Douglas’ hermetic motor terminals provide a secure electrical interface between the hermetically sealed chamber and the external environment while ensuring long-lasting performance. Whether it’s in high-speed motors, precision motors, or motors subjected to extreme conditions, our custom solutions enable efficient power transmission while maintaining a hermetic seal.

- Compressor Applications: Compressors operate under high-pressure conditions, demanding airtight sealing solutions. Douglas’ hermetic power feedthroughs offer unparalleled reliability, ensuring that electrical connections remain impervious to pressure differentials. Our high-power feedthroughs are engineered to withstand harsh environments, ensuring optimal compressor performance and minimizing downtime. With our expertise, we provide sealing solutions that meet the stringent requirements of various compressor applications.

- Chamber Applications: In vacuum and pressure chambers, maintaining an airtight seal is crucial to prevent leakage and contamination. Douglas’ hermetic power feedthroughs provide dependable electrical connections to interface with the chamber walls, guaranteeing the integrity of the system. Our hermetic high-power feedthroughs are designed to resist extreme temperatures, corrosive substances, and mechanical stresses, making them the ideal choice for a diverse range of chamber applications. We can design hermetic plate assemblies incorporating both power and signal capacities into a single process port.

Douglas Electrical Components is at the forefront of designing and manufacturing hermetic power feedthroughs that meet the stringent sealing requirements of vacuum and pressure applications. With a focus on motors, compressors, and chambers, our solutions offer exceptional reliability, durability, and performance. By partnering with Douglas, customers can confidently rely on our expertise and cutting-edge technology to achieve leak-free electrical connections in their critical systems.

Locate a Technical Sales Engineer

Features

FEATURES

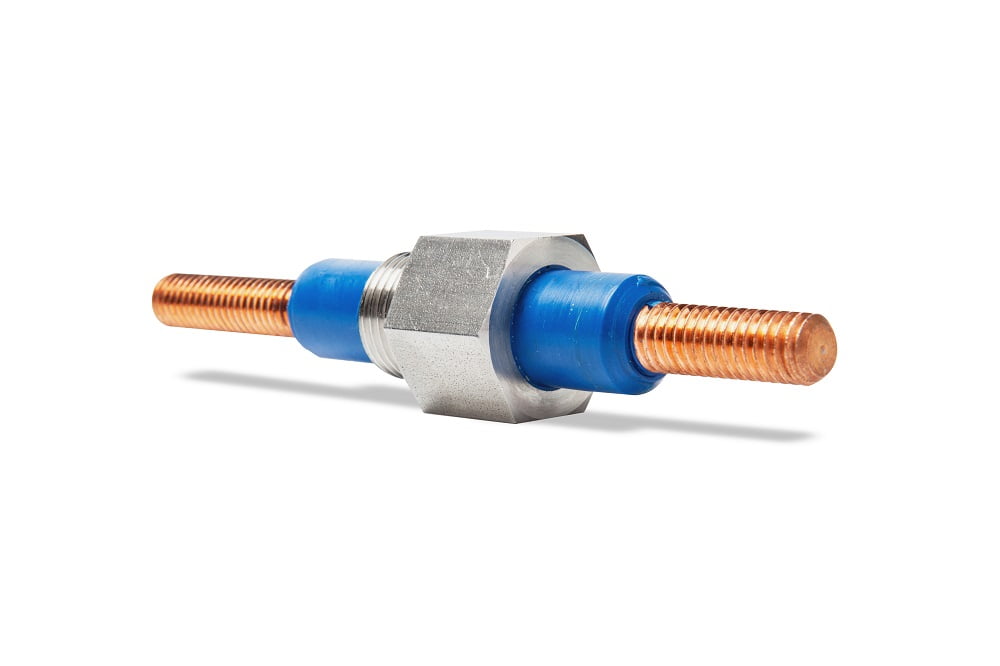

- Use our standard StudSeal hermetic terminal seals or customize your design to meet electrical and environmental conditions

- Design for power applications exceeding 1,000 amps and 15,000VAC

- Operate in harsh and hazardous environments including temperatures from cryogenic to 200°C and pressures of 10,000 PSI

- Design the exact mechanical interface from standard thread connections to custom flanges and plates

- Standard brass and copper conductors with simple ring terminals; customize based on your needs

- Epoxy insulation

ELECTRICAL CONNECTION TYPES

- Threaded stud terminals (male and female)

- Right-angle studs

- Stud-to-wire

- Busbar

- Tubes

- Pins

- and more

Douglas can not only design your terminal seal with each of these type, but also combine them to have different types of conductors inside and outside the system, chamber, glovebox, motor, or compressor.

MARKET CAPABILITIES

- ISO 9001:2015

- ISO 14001:2015

- UL984 Standard for Hermetic Refrigerant Motor Compressors

- ITAR DDTC Registration

FAQ

What is a hermetic power feedthrough?

A hermetic power feedthrough is a device used to transfer power or signals through a sealed barrier, such as a vacuum or pressure vessel. It is designed to maintain a hermetic seal while allowing for the transfer of electrical power or signals.

What materials are used in StudSeal hermetic power feedthroughs?

Our hermetic power feedthroughs use some standard materials for power feedthroughs.

- Conductors / Terminals: Copper or brass are standard

- Housings: Aluminum and stainless steel are standard

Customization of material depends on the specific application and the requirements for temperature, pressure, and chemical resistance.

What industries use StudSeal hermetic power feedthroughs?

StudSeal hermetic power feedthroughs are used in a variety of industries, including aerospace, defense, industrial, glovebox, cryogenic, hazardous locations, medical, and semiconductor manufacturing. They are also used in research and development applications, such as in vacuum chambers for testing and experimentation.

How are StudSeal hermetic power feedthroughs installed?

StudSeal hermetic power feedthroughs are typically installed by drilling a hole in the barrier and inserting the feedthrough. The feedthrough is then secured in place using a nut or other fastener. The installation process may vary depending on the specific application and the type of barrier being used.

Does Douglas Electrical Components offer wire or connector options for transmitting power?

Yes, Douglas can either combine our connectors or wires with stud-type feedthroughs or offer designs with connectors and/or wires. In some cases, we also design hybrid designs which incorporate power and signal as well as the ability to add optical fiber into the same feedthrough.

Can StudSeal hermetic power feedthroughs withstand extremely high and low temperatures?

Yes, hermetic power feedthroughs can withstand extremely high and low temperatures from cryogenic to 200°C and pressures of 10,000 PSI.

Image Library

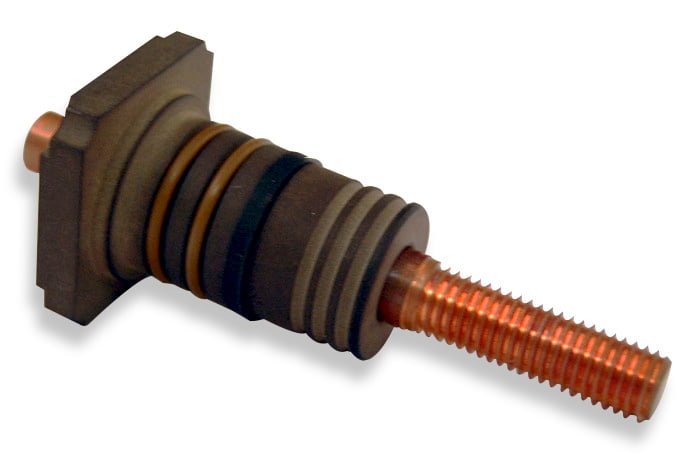

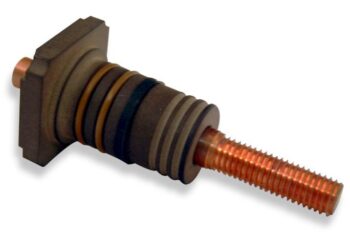

Motor High Power Terminal Seal

Motor high power terminal feedthroughs with NPT and copper studs work in compressors ranging in size from fractional horsepower to high-tonnage.

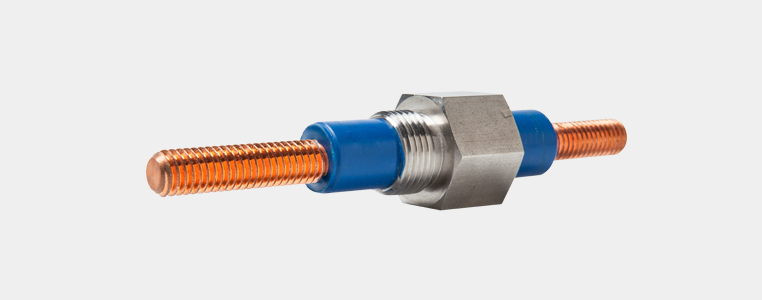

Radial O-ring Compressor Terminal Seal

Radial O-ring compressor feedthroughs reduce customer install time while utilizing a low cost molded housing.

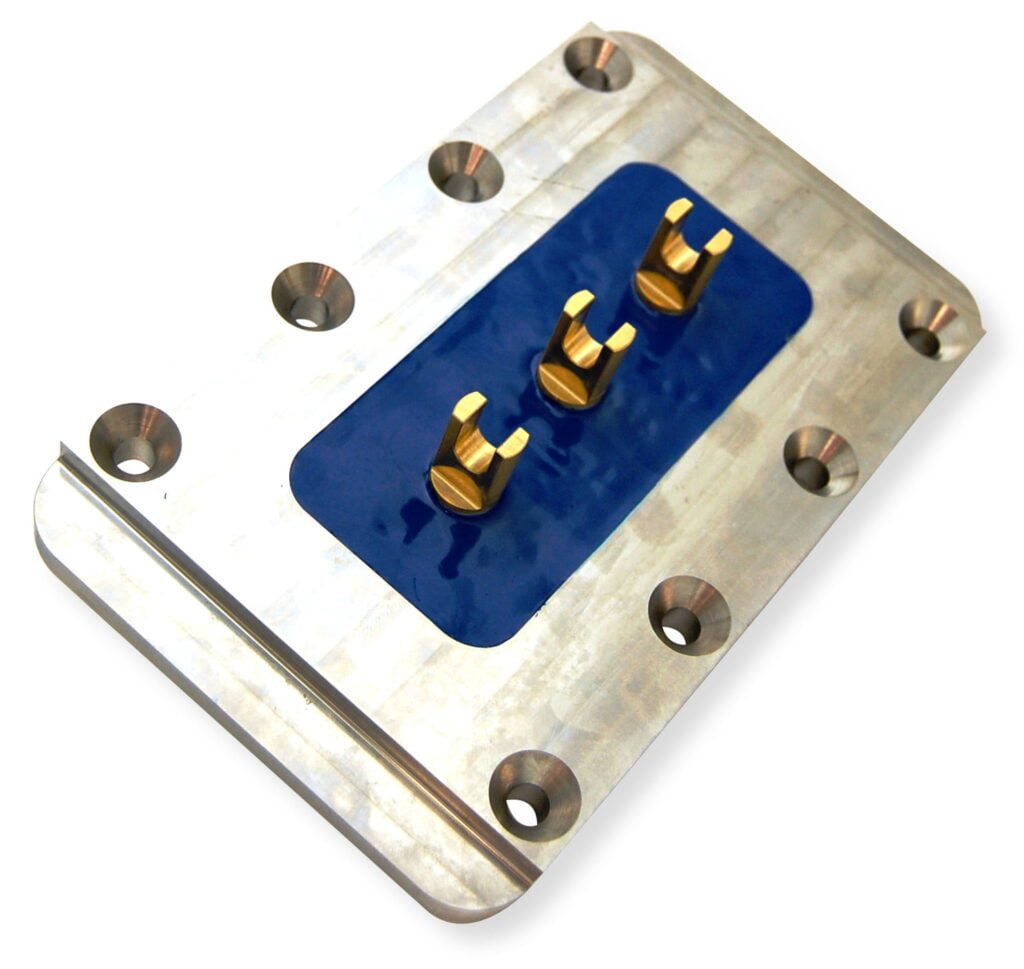

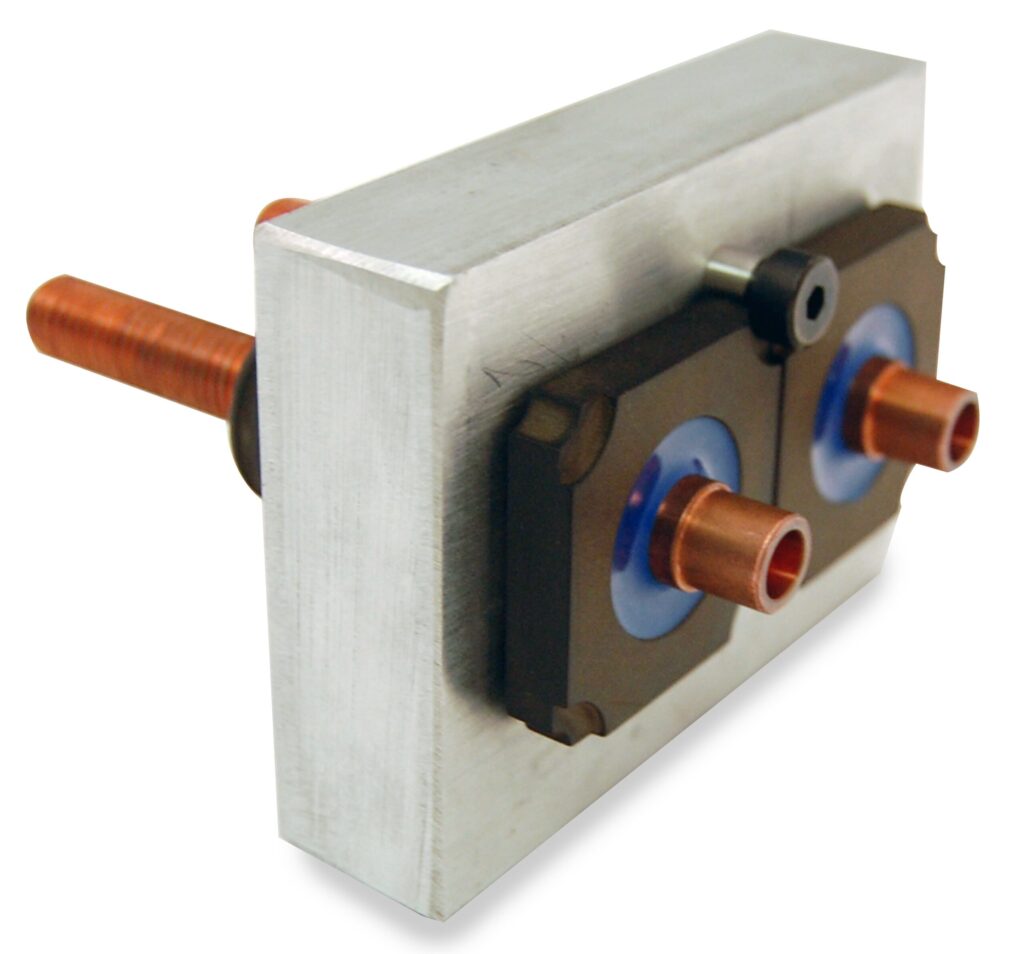

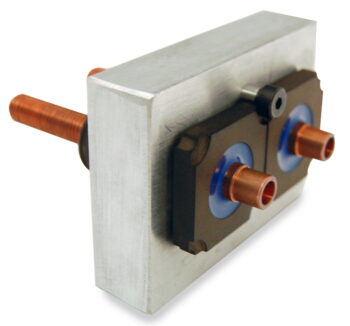

StudSeal rectangular flange power feedthrough

Custom flange with integral hermetic terminals for power transmission.

Threaded and Tabbed Hermetic Terminal Seal

Threaded studs in custom housing.

Right-angle StudSeal Power Feedthru

StudSeal power feedthrough with right angle connections are available as well as threaded studs. High current studs of our hermetically sealed electrical connectors handle up to 1,000 amps to meet most of process power needs.

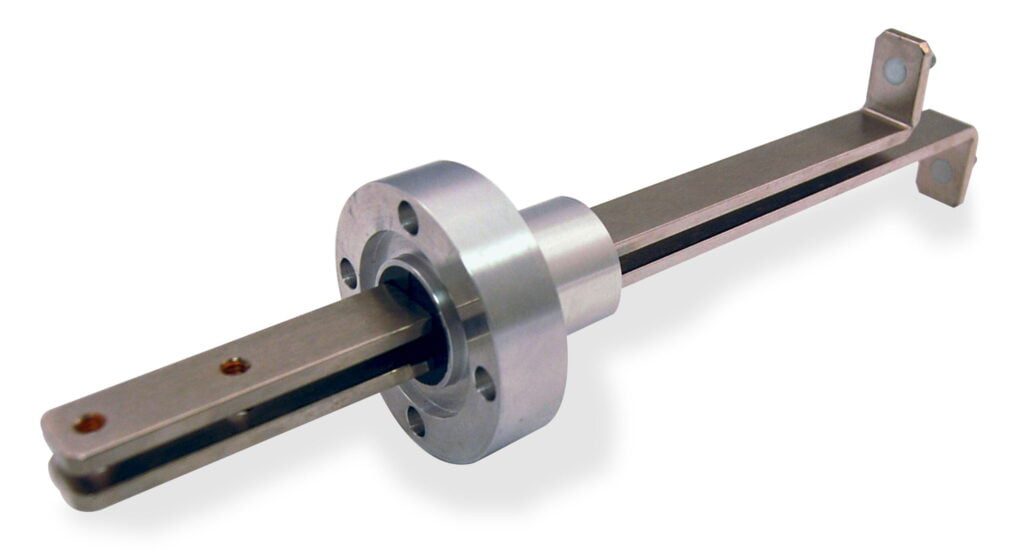

Busbar power feedthrough assembly

Busbar hermetic power feedthrough assembly

Hermetic Terminal Seal with stud to wire assembly

Terminal to wire hermetic seal design with CF Flange.

Hermetic Terminal to Wire side view

Customized hermetic motor terminal seal showing complete assembly

StudSeal Customized Feedthrough

Customized hermetic terminal seal material and mechanical interface

PotCon Power Feedthrough Assembly

PotCon hermetic power feedthrough assembly. Hermetically seal cables directly into the bulkhead connector assembly.

Custom Hermetic Terminal Seal

StudSeal hermetic terminal seal with multiple studs

Hermetic Terminal Plate Assembly

Customized hermetic terminal plate assembly

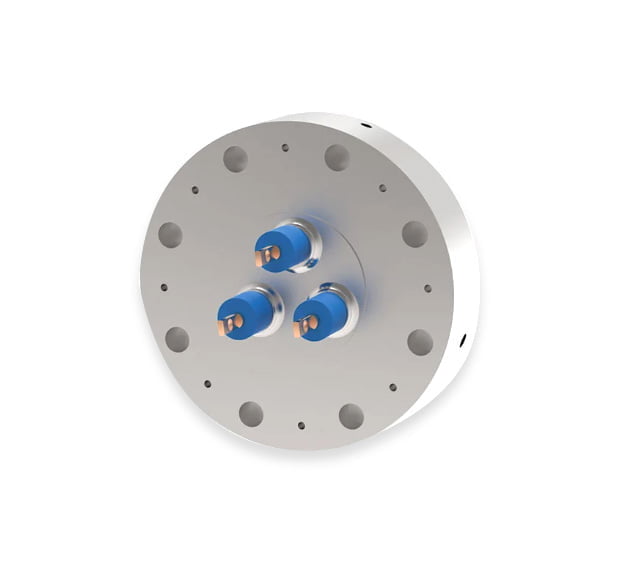

Power and Signal Hermetic Flange

Combine power and signal feedthroughs into a single PortPlate design.

Cryogenic Power Feedthrough

Cryogenic Feedthrough design with three power feedthroughs integrated into a custom flange.

StudSeal Copper Terminal Plate

Customized hermetic terminal plate assembly

Quick connect electrical feedthrough for power

Quick connect electrical feedthrough for power

Related Documents

Documents & Downloads