Explosion-proof / Flameproof Explosion-proof wire and cable bushings

Sealed Line Bushings for Hazardous Locations

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

Douglas Electrical Components offers an extensive range of explosion-proof wire and cable seals for simplified engineering in hazardous locations. Our wire and cable seals, commonly referred to as line bushings, offer unique design features that enhance efficiency and reliability of your applications. Available standard with threads in various sizes, these explosion proof cable bushings are pre-wired and sealed for drop-in use, from the factory to the field. The bushing is pre-potted with our moisture-tight, hermetic epoxy to protect either side of the feedthrough from air or liquid penetration. Specify virtually any wire or cable type (with the ability to combine different size conductors) within a single assembly and receive a pre-tested and certified cable bushing ready for install.

With a longstanding expertise in hermetically sealing wires and cables, Douglas can create a high-density cable and wire feedthrough with various jacket materials. Our wire and line bushings use a hermetic epoxy that offers excellent chemical compatibility, thermal properties, and mechanical properties, exceeding various UL and ASTM standards for process seals.

Benefits of Explosion Proof Wiring and Cable Bushings

Our explosion proof cable and wire bushings stand out due to the following reasons.

- Enhanced crack resistance: Unlike cement-based sealants prone to cracking and fatigue, our UL 1203 Ethernet cable bushings utilize epoxy seals. These seals exhibit exceptional resistance to mechanical and environmental stresses, eliminating the need for compromising wire-and-cable product choices.

- Combined explosion and process seal: In addition to safeguarding against sparks, flames, and dust, our UL 1203 bushings for cables and wires provide a hermetic process seal. With leakage rates as low as <1×10-9 cc-He/sec, they can withstand application pressures up to 10,000 psi and burst pressures exceeding 15,000 psi. This eliminates the need for separate seals in pressurized environments.

- Simplified electrical system design: Simplify your electrical system design in hazardous locations with our reliable and efficient UL listed explosion-proof wire bushings. You can see various examples of products that integrate various wire and cable types with or without armored jackets, as well as hermetic solutions that are customer-specific designs added to our certification file or yours.

Applications of Explosion Proof Electrical Wire Bushing

Our explosion-proof electrical wire bushings are designed for use in hazardous-atmosphere applications in hazardous environments. Some common applications of explosion-proof cable bushing include:

- Alternative energy fuel systems

- Analytical instrumentation

- Compression equipment

- Control panels

- Cryogenic systems

- Gas engines and turbines

- Fiber optic communications

- Marine equipment, sensors and transducers

- Upstream wellhead monitoring equipment

ATEX / IECEx Ex-proof Cable Bushings

Douglas offers cable bushings certified to ATEX and IECEx Ex d flameproof standards. You can integrate ATEX and IECEx rated wires and cables directly into a sealed ex proof cable assembly. Our line bushings can be directly integrated into instrumentation and flameproof enclosures, simplifying installation without sacrificing agency approvals.

You can contact our factory to explore the possibilities of designing our hermetic sealing capabilities into your specific electrical cable bushing and electrical circuit designs. By gaining hazardous area rating and quality standards (QAR/QAN), Douglas can streamline the process to a customized approved solution for OEM applications.

Image Library

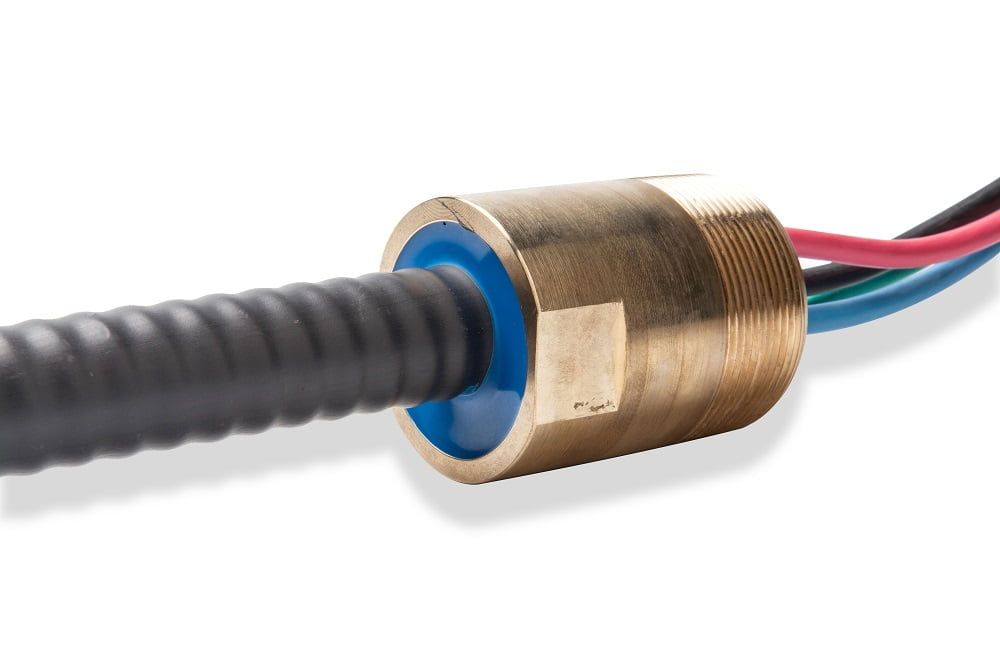

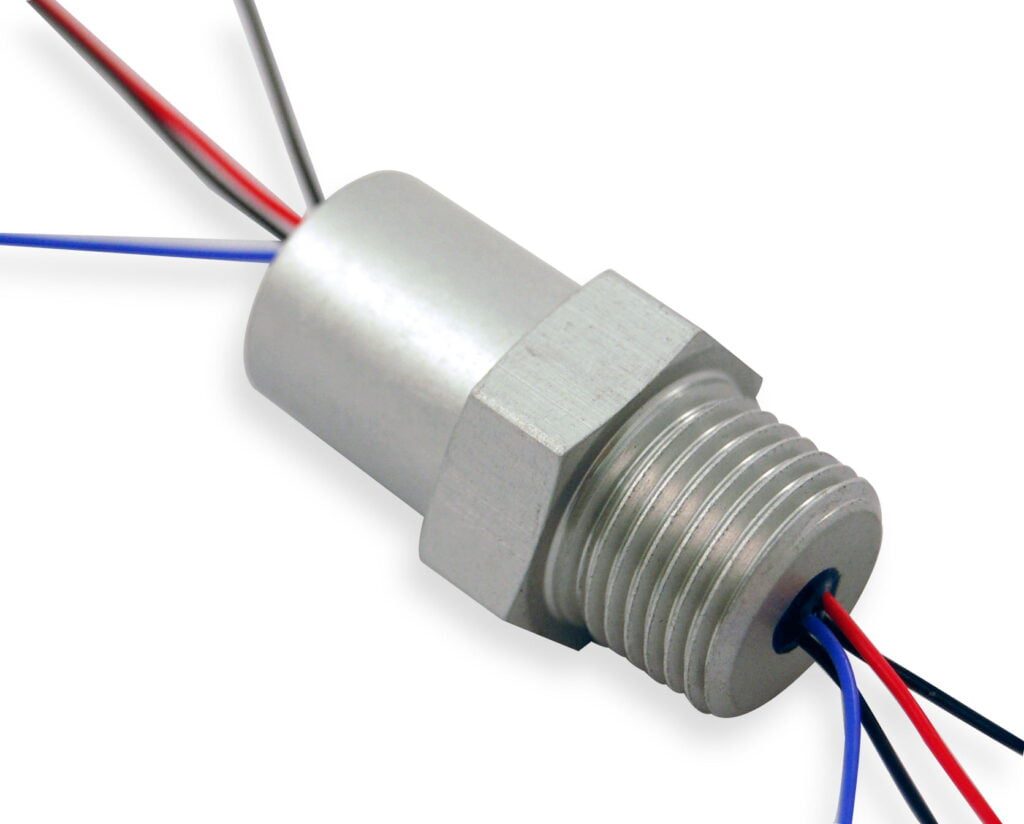

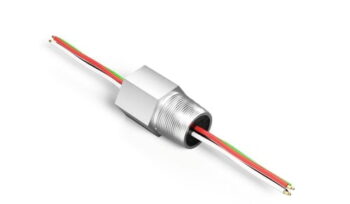

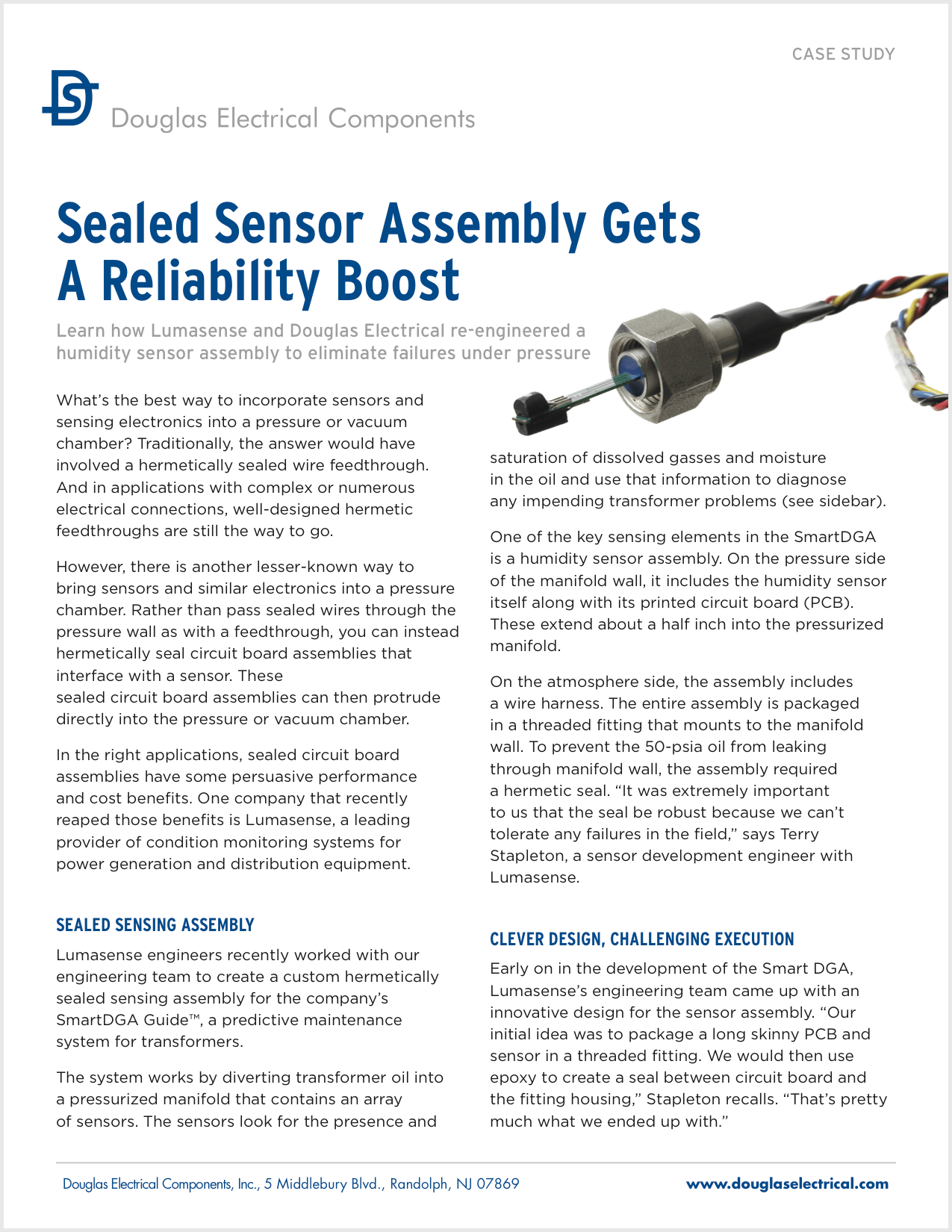

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

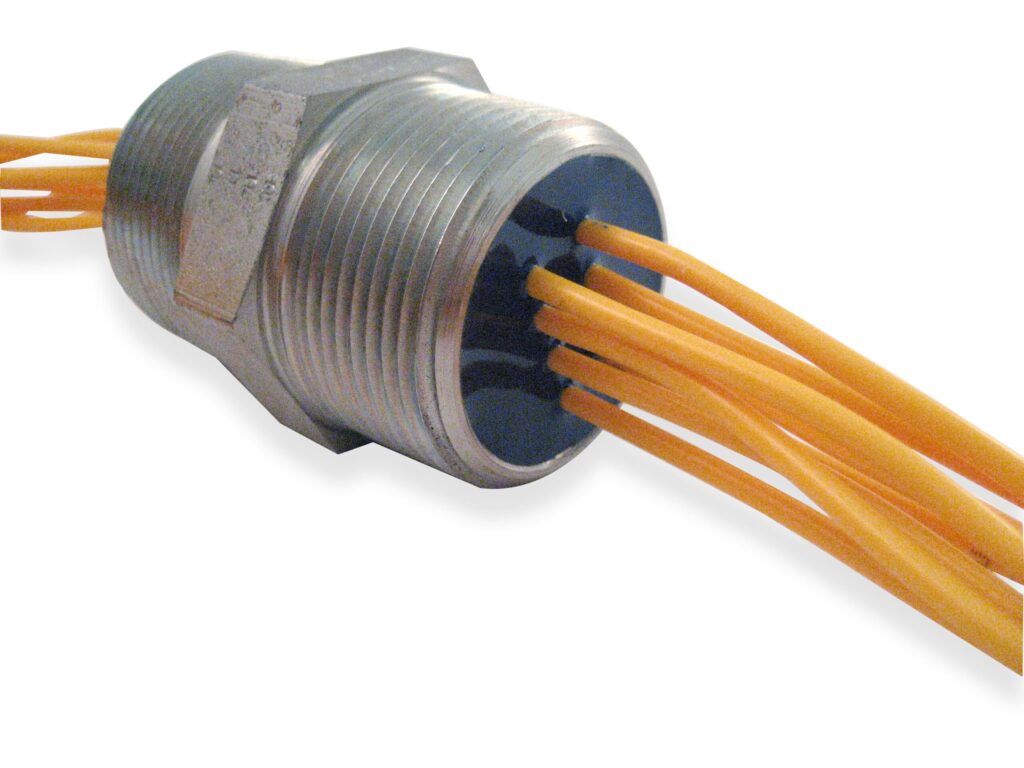

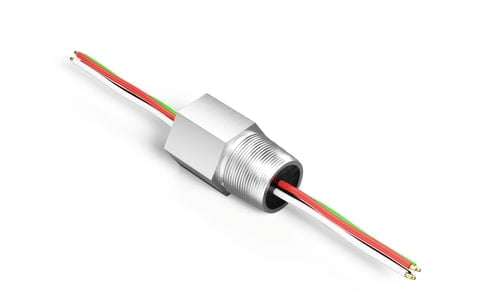

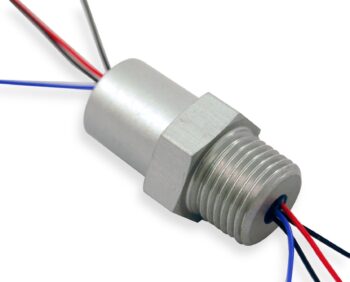

Explosion-proof NPT Wire Bushing

Side view of Explosion-proof NPT wire bushing with standard aluminum housing

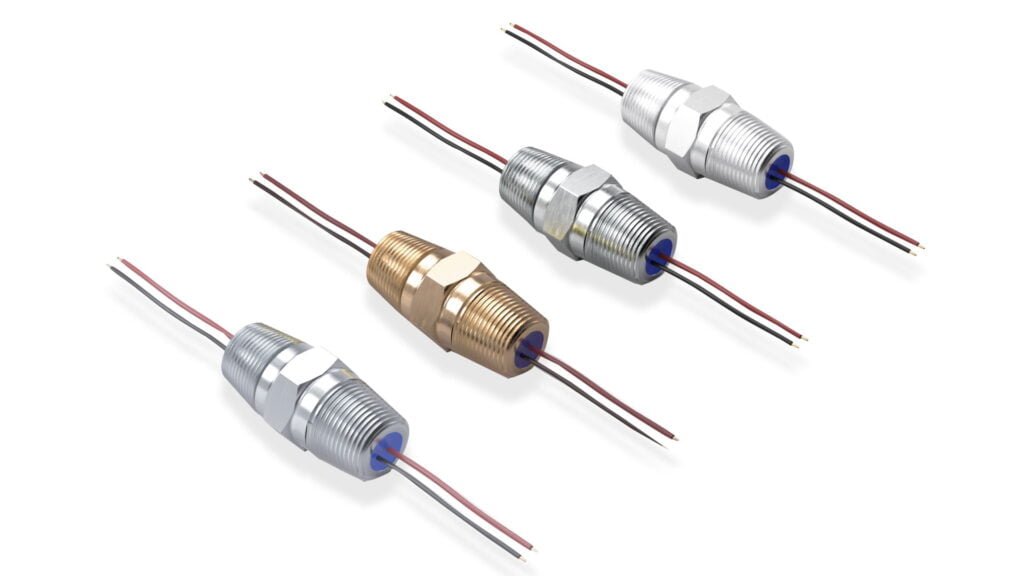

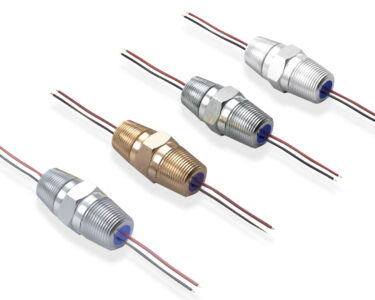

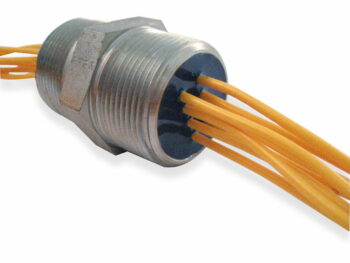

52539 Male-to-female Explosion-proof Wire Bushing

Male to female NPT feedthroughs for explosion-proof applications available in various materials.

NPT Feedthroughs

NPT Feedthroughs, also referred to as wire bushings, are available in various conductor sizes, counts, and configurations for hazardous and non-hazardous applications.

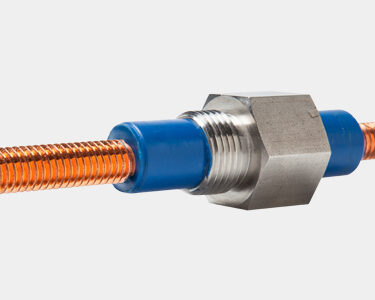

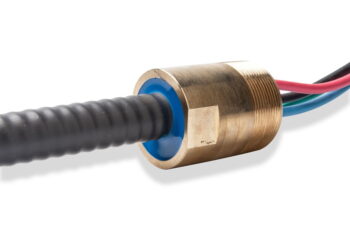

Ex-proof Conduit Seal

explosion-proof conduit seal with cable to wire configuration and armor jacket

Hermetic Coax Wire Feedthrough

Hermetic coaxial feedthrough with NPT threads and coaxial wires

Explosion-proof NPT Conduit Seal

Explosion-proof NPT Conduit Seal with male and female threaded ends

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

Oil and Gas Power NPT Feedthrough

Designed with larger gauge wire for power transmission

DuctorSeal NPT threaded explosion-proof cable seal

Standard NPT wire bushing for instrumentation and controls with explosion-proof rating

Turnkey Terminated NPT Cable Feedthrough.

Designed for plug-and-play application

NPT Explosion-proof Cable Assembly

Explosion-proof conduit seal with NPT threads can be designed for hazardous locations including explosion-proof environments.

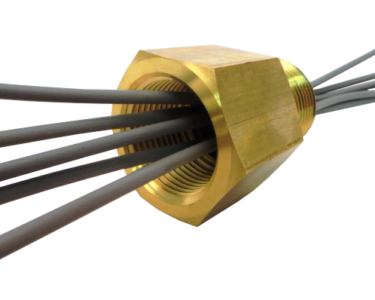

Explosion-proof Brass Wire Bushing

Explosion-proof Brass Wire Bushing design in female-to-male configuration. Avoid cement sealing wire bushings in the field by using an explosion-proof rated assembly sealed and tested at Douglas Electrical.

Hermetic NPT Thermocouple feedthrough

A wire bushing style feedthrough with NPT threads and thermocouple wires

DuctorSeal Wire Feedthru

Multi-conductor hermetic wire feedthrough with NPT Threads

Multi-Fiber Type Feedthrough

Hermetic fiber optic NPT feedthrough with SM and MM fiber in the same mechanical interface.

Features

FEATURES

- Create high-density hermetic electrical feedthroughs with integral wires, cables, and optical fibers to UL/cUL Class I Div 1 Explosion-proof ratings

- IEC 60079-0:2017 Edition: 7.0 – Explosive atmospheres – Part 0: Equipment – General requirements available

IEC 60079-1:2014 Edition: 7.0 – Explosive atmospheres – Part 1: Equipment protection by flameproof enclosures “d” available - Use the same wire and insulation types already approved for use elsewhere in your system

- High-voltage cables > 30,000 V

- Full cable harness options with connectorization available performed by IPC-620 operators

- Custom bifurcated fiber assemblies with a combination of optical and copper conductors

- Ingress Protection exceeds IP-69K and NEMA 6P

CAPABILITIES

- NPT housings, conduit fittings, ASA flanges and custom designs for use in assemblies that comply with UL, CSA, IECEx, ATEX, and FM explosion proof standards.

- Capable of meeting the following international hazardous location standards for flame proof, increased safety, pressurized and oil filled enclosures:

- IEC 60079-0, IEC/EN 60079-1, IEC/EN 60079-2, IEC/EN 60079-6 and IEC/EN 60079-7

- ATEX Ex d, ATEX Ex e, ATEX Ex de, and ATEX Ex pD

- CSA 22.2, CSA E60079

- UL/cUL 1203, UL 886, UL 674 and UL 913

- FM 3611, FM 3615, FM 3620 and FM 3610

- IP-69 and above, NEMA 6P and above

QUALITY

- Leak Rate testing: <1×10-9 scc He/sec (std atm temp)

- Point to point continuity

- Insulation Resistance, Hipot testing

- Pressure testing >12,000 PSI

- Thermal cycling and thermal aging

- Optical insertion loss and back reflection

Featured Products

FAQ

What housing and fitting materials are used in the manufacturing of Douglas’ explosion-proof wire bushings?

We offer three standard materials for explosion-proof wire bushings: aluminum, brass, and stainless steel. With in-house CNC machining, Douglas can machine housings and fittings quickly and to our quality standards.

Douglas offers NPT and metric housing for standard certified wire and line bushings.

What cable and wire materials are available for explosion-proof wire bushings?

Douglas Electrical Components has the unique ability to hermetically seal to virtually any conductor or optical fiber. Standard materials in our hazardous location portfolio include PTFE, PVC, and THW.

For IECEx and ATEX rated products, design your explosion-proof wire or cable seal with any wire or cable that meets the flameproof standard.

What wire gauges are possible?

Wire bushings are available in wire gauges from 18 AWG to 3/0, depending on the fitting side and number of conductors. Contact the factory to help configure your design.

What are the standard fittings for Douglas’ explosion-proof wire bushings?

1/2″, 3/4″, and 1″ NPT housings are standard. The NPT threads can be designed as male or female on either end of the fitting. For non-standard applications, contact our sales engineers to review our capabilities to add mechanical designs to our file.

IECEx and ATEX bushings utilize both metric and NPT thread options.

Are all Douglas wire bushings hermetic?

No. Douglas offers both hermetic and non-hermetic versions of our explosion-proof product line. Our non hermetic designs are moisture-tight seals for less critical sealing requirements.

Documents & Downloads

Literature

Whitepapers

Versatile Hermetic Epoxy Seals Protect Fiber Optic Cable and Ensure Signal Quality

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations