MIL-DTL-5015 and MIL-DTL-38999 are United States Military Standards for circular connectors used in various military and aerospace applications. These connectors ensure that critical systems maintain operational integrity in extreme environments, thus highlighting their essential contribution to the safety and effectiveness of many military and aerospace operations. Although these connectors may look similar, they differ in terms of characteristics and applications. This post delves into the details of these connectors.

MIL-DTL-5015 Connectors: A Brief History of Evolution

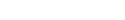

24056 Hermetic Bulkhead Connector with vacuum face seal and MIL-DTL 5015 plug and receptacle

MIL-DTL-5015 connectors, originally referred to as MIL-C-5015, have been around since the 1930s, which makes them one of the oldest and most popular military connectors in use today.

- These circular connectors were originally developed by Cannon, now known as ITT Interconnect Solutions, for DC-1 Aircraft.

- This connector’s specification was released as the AN9534 standard in 1939 and was superseded by AN-W-C-591 in 1941.

- The emergence of the US Air Force during WWII has paved way for the evolution of these connectors over the years. In 1949, the AN-W-C-591 became MIL-C-5015 Connector and it was the first specification of a coordinated connector approved for the use by the US Army, Navy, and Air Force.

- MIL-C-50515 Connector was renamed MIL-DTL-5015 in 1994.

- In 2009, this standard was superseded by SAE-AS5015 by the United States Department of Defense.

Features of MIL-DTL-5015 Circular Connectors

The MIL-DTL-5015 circular connectors are no longer officially in use today; however, they still make an excellent choice for various applications.

- Design: These connectors are offered in various rugged materials and finishes, such as aluminum, zinc, stainless steel, and so on. They can perform across various operating conditions in aerospace, heavy machinery, and automotive industries where moisture, vibration, pressure, and temperature can be extreme.

- Coupling Mechanism: MIL-DTL-5015 connectors use a single-start thread, which has an excellent self-locking property. It means these connectors won’t loosen easily.

- Polarization: MIL-DTL-5015 connectors feature only one keyway, which limits its ability to mis-mate in complex applications.

- Contact Count: MIL-DTL-5015 circular connectors are available in various shell styles, such as straight, wall receptacles, right angle, cable plug, and so on. These connectors can support up to 128 contacts based on their shell styles.

- Wide Range of Allowable Contact Voltages and Currents: These connectors are available in a wide range of allowable contact voltages and currents, up to 200 A for Series 1.

- Applications: MIL-DTL-5015 spec connectors are used in legacy military equipment, industrial equipment, and high-current applications, such as

- Power Generators

- Off-road Vehicles

- Engines

- Earth-moving Equipment

- Mobile Equipment

MIL-DTL-38999 Connectors: A Brief History of Evolution

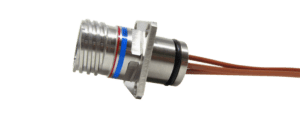

MIL-DTL-38999 connector assembly with integral hermetics and wires in high pressure housing

MIL-DTL-38999 connectors were introduced just before WWII. The original specifications for these connectors were laid in the 1930s and were known as Army-Navy (AN). MIL-DTL-5015 was the forerunner for these connectors. MIL-DTL-5015 were extremely popular through the 1950s and 60s, but they had certain drawbacks. The need for improved connectors arose and that’s how MIL-DTL-38999 connectors came into existence.

MIL-DTL-38999 connectors were not only military standard, but also designed to meet the demands of applications used in the US Army, Navy, and Air Force. The new connectors were designed to support high contact density in a relatively small size. This made them ideal for applications where weight and space were crucial aspects. These connectors evolved over the years to assure better rust resistance and waterproof capabilities than MIL-DTL-5015.

Features of MIL-DTL-38999 Connectors

MIL-DTL-38999 connectors are better in terms of weight, efficiency, and performance over MIL-DTL-5015 standard connectors. Key features of these connectors, include:

- Design: These connectors are available in multiple series offering different features. For instance, MIL-DTL-38999 Series I Connectors are circular, Bayonet style, high contact density connectors offered in shell sizes ranging from #9 to 25; MIL-DTL-38999 Series II Connectors are circular, high contact density, Bayonet style connectors in low profile shell sizes ranging from #8 to 24; and MIL-DTL-38999 Series III Connectors are circular, high-density, screw-coupling connectors in shell sizes ranging from #9 to 25.

- Coupling Mechanisms: These MIL-DTL-38999 connectors are available in several coupling styles, including Bayonet, threaded, and breech-lock, allowing for flexibility in application.

- Polarization: These connectors use multiple keyways for preventing the mis-mating in complex systems.

- Contact Count: These connectors can support up to 156 contacts, depending on the shell sizes and series.

- Current Rating: The current rating of these connectors is up to 150A.

- Applications: These connectors are a popular choice for modern military and aerospace equipment due to their versatility and environmental resistance. They are employed in applications such as:

- Vehicle and hand-held platforms

- Marine Electronics

- Communications Equipment

- Medical Equipment

- Weapon Systems

- Armored Carriers

- Tanks

- Military aircraft

- Military ground support systems

- Aircraft engines

- Aerospace launch vehicles

- Electrical testing equipment

- Blind-mate applications

- Commercial aviation

- Unmanned systems

How to Choose the Right Connector for Your Needs

Hermetic feedthrough assembly with integral MIL-spec cable harness

The choice of the right connector will depend on your specific needs. For instance:

- If you need a high-current connector for a legacy system or industrial application, MIL-DTL-5015 might be suitable.

- If you need a versatile connector for modern military or aerospace equipment with various environmental requirements and features, MIL-DTL-38999 is a better choice. You’ll also find more commercial interconnects within the 38999 housing such as USB and RJ-45.

Douglas Electrical: Your Trusted Source for Customized MIL-DTL-38999 Connectors

MIL-DTL-38999 circular connectors can efficiently handle power and data requirements in military and aerospace applications. At Douglas Electrical, we specialize in customizing the MIL-DTL-38999 circular connectors that can be easily converted to hermetically sealed assemblies to meet your precise requirements. You can choose from Series I, II, III, and IV Circular Connectors 38999 Series and trust us to customize them as per your requirements. We can customize these connectors with integrated terminals and pins, fiber assemblies, cables, wires, etc.