The importance of secure and reliable connections cannot be understated in vacuum systems. Airtight sealing is one of the essential requirements of this industry, and it can be achieved using many components including hermetic BNC connectors. Although they may seem simple, these connectors have a lot more to offer. This post aims to demystify hermetic BNC connectors, while focusing on their design, importance, types, installation, and maintenance, and many more.

Introduction to Hermetic BNC Connectors

A Bayonet Neill–Concelman connector or BNC connector is a type of coaxial radio frequency (RF) connector.

It is mainly used in electronic architectures such as video, audio, and networking to connect voltages below 500V and mainly radio frequencies up to 3GHz. These connectors are designed for low signal losses, contributing to their increasing use in various high-performance analog communication avionics and test equipment. BNC connectors are distinguished into twist-on, F-compression, F-crimp connector, and crimp-on types.

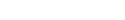

Hermetic BNC connectors or BNC feedthroughs are a specialized type of BNC connectors that use the same form factor as any regular BNC connector, but create secure and airtight or leak-free connections. The hermeticity of these BNC feedthroughs is ensured by employing advanced sealing technologies. These connectors are used in applications where it is crucial to prevent the ingress of moisture, gases, dust, and other environmental factors affecting the connections. Hermetic BNC connectors are available in various configurations, including panel-mounted, bulkhead-mounted, and cable-mounted versions.

Benefits of Using Hermetic BNC Connectors

-

- Hermetic BNC connectors are employed in moisture-sensitive and vacuum environments, where a high level of sealing is required for protection against moisture and other environmental factors. Here are some benefits of using hermetic BNC connectors in such conditions:

- Moisture Resistance: Our hermetic BNC connectors feature our proprietary low outgassing hermetic epoxy sealed between the connector and housing. This creates an airtight barrier around the connector. It prevents moisture and other contaminants from entering the connector and compromising its performance.

- Environmental Protection: These connectors are designed using robust materials, such as stainless steel or steel-based alloys that lend durability and corrosion resistance to them. Stainless steel and steel-based alloy materials can withstand dust, dirt, chemicals, and gases as most standard BNC connectors cannot tolerate these conditions.

- Reliability in Ambient Pressure and Temperature Conditions: These connectors can withstand the fluctuations in ambient pressure and temperature conditions without compromising their sealing ability. This is why they are used for applications operated in environments like deep-sea, outer space, high altitudes, and so on.

- Customization Options: Hermetic BNC connectors can be designed in various configurations, including feedthrough connectors, bulkhead connectors, and panel-mount connectors. This allows for their easy integration into different systems.

If you have considered these connectors for your vacuum-based or moisture-sensitive applications, ensure to source them from trusted manufacturers like Douglas Electrical Components. This next section explores how you can realize the benefits of sourcing from Douglas Electrical Components.

Why Consider Hermetic BNC Connectors from Douglas Electrical Components for Your Vacuum or Moisture-sensitive Environments

Douglas Electrical Components designs BNC connectors that cater to various applications. These connectors are designed to meet customer-specific as well as standard requirements. The following features of these connectors have contributed to their increasing popularity in vacuum applications.

- They are designed to offer sealing for high vacuum environments as well as pressures up to 15,000 PSI and cryogenic temperatures up to -350°F.

- BNC connector feedthroughs are available with leak rates <1×10-9 cc-Helium/sec.

- They feature environmental sealing or hermetic/waterproof back potting, which is done using Douglas’ proprietary process.

- These connectors can be directly integrated with various electrical connections in the vacuum or pressure environment including connectors, cables, and circuits

- Hermetic BNC connectors designed by Douglas Electrical Components feature plug-and-play drop-in assembly.

- Douglas Electrical Components has developed the PotCon® line of hermetic bulkhead connector feedthroughs, which are being increasingly employed in hermetically sealed environments such as semiconductor processing equipment and UHV testing system.

- PotCon® BNC bulkhead feedthroughs feature wire harnesses and connectors in a single, fully sealed housing.

- The circuits in these feedthroughs are designed to disconnect at a vacuum port or the pressure bulkhead while maintaining hermetic sealing for both signal as well as power applications. This simplifies the mating and un-mating of electrical connections in vacuum environments.

- All BNC feedthrough connectors are designed, manufactured, and engineered at Douglas Electricals’ ISO 9001/14001 facility. We can also provide ITAR/DFAR-compliant connectors on request.

Are you looking for BNC feedthrough connectors for vacuum environments? Contact us today to discuss your requirements. Our experts will happily answer your queries and deliver the best solutions for your requirements.