JacketSeal™ Series Liquid Tight Wire / Cable Feedthrough Seals

Create a high-density, sealed wire or cable electrical feedthrough

for use in hazardous and/or non-hazardous areas.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

JacketSeal™ sealed electrical feedthroughs provide a liquid/fluid/water-tight sealing solution where a true hermetic seal is not required. Sealed electrical feedthroughs are commonly used applications that require mild water blocking or sealing to IP-67, IP-68, NEMA, and explosion-proof standards. JacketSeal™ technology can be integrated into various sensor, instrumentation, and transmitter designs, simplifying the manufacturing process while reducing exposure of electronics to environmental conditions. As the cable or wire passes through the mechanical interface, the epoxy bonds to the conductors using a proprietary process to protect against liquid and gas penetration.

JacketSeal™ wire and cable feedthroughs (sometimes referred to as a waterproof cable joint or passthrough) are designed for applications that are submerged in liquids such as equipment in flood-prone areas or directly into sensors and instrumentation submerged in liquids. The cable or wire feedthrough assembly can integrate a variety of cable and conductor material types as well as a customized housing. The housing is the mechanical interface in which the product is sealed. It can be machined from a variety of metals to ensure the best chemical compatibility or molded from custom materials.

Our epoxy creates a liquid-tight seal against the housing, conductors, and wire jackets to prevent the penetration of liquids including waters and fuels. Our fuel-resistant epoxy is used in a variety of monitoring applications with long-term installations. Customers can integrate a combination of wires, cables, connectors, and fibers into a single assembly and choose from a housing or bulkhead fitting option. Other design options include connector integration, cable armor or shielding, labeling, and more.

In addition to stand-alone use, JacketSeal™ connections can also be integrated into hermetic feedthroughs to provide fluid blocking or a sealed, explosion-proof cable assembly. While commonly designed as a wire bushing assembly, Douglas Electrical Components can machine various materials into the electrical connections required to meet your needs. The feedthrough can come designed with integral connectors to save installation time within your transmitter or system. The certification can be processed by Douglas or designed to meet agency standards and integrated directly within customer files.

- A wide variety of primary and secondary explosion-proof ratings in accordance with UL, FM, IECEx, CSA and ATEX requirements.

- Availability as an option on DuctorSeal®, CircuitSeal™ and OptiSeal™ product lines.

Features

PERFORMANCE CAPABILITIES

- Wide variety of primary and secondary explosion-proof ratings in accordance with UL, FM, CSA, IECEx, and ATEX requirements.

- IP-rated up to IP-68 electrical feedthroughs on jacketed cables or individual wires

- Pressures of 15,000 psi

- Operating temperatures range from 4 K (LHe) through high temperatures of 200°C

- Full strain relief available for cable assemblies

COMMON WIRE AND CABLE TYPES

- Individual wires (PTFE, PVC, etc.)

- Jacketed cable

- Coaxial cable including Triax, Quadrax, and Twinax cable

- Thermocouple

- Customized assemblies with integral connectors

MARKET CAPABILITIES

- ISO 9001:2015 / ISO 14001:2015

- UL1203 Class I Division 1 Explosion-proof

- IPC-620 Certified Technicians

Featured Products

FAQ

What is the difference between DuctorSeal and JacketSeal?

DuctorSeal wire feedthroughs are specifically designed for hermetic applications where as JacketSeal is liquid or gas sealing is required for an application.

DuctorSeal will hermetically seal directly at the conductor, creating a true hermetic seal against liquids and gases.

JacketSeal seals to the jacket of the conductor rather than the actual exposed conductor. Both designs are specified for hazardous locations, yet the level of sealing is determined by the application.

What is the difference between hermetically sealed and a sealed connector?

While the cable and connector industries can use the terms interchangeably, a hermetically sealed connector is physically sealed to a vacuum standard, such as 1×10-9, to ensure the leakage rate is minimal. Sealed connectors refer to external environmental conditions such as water and dust penetration with standards such as IP (Ingress Protection) and NEMA (National Electrical Manufacturers Association) ratings are common. NEMA standards will also cross over into those for use in hazardous location environments, where approval standards such as IEC, ATEX, and others exist for sealed protection against explosions.

Can JacketSeal be combined with other Douglas Electrical Products?

Yes. As an example, a JacketSeal cable assembly can be combined with our DuctorSeal technology when both a water-tight seal and a hermetic seal are required for the application.

Is JacketSeal used in sensor and instrumentation applications?

Yes. Sensors and instrumentation applications are common for JacketSeal designs. Since sensors require both power and signal transmission, a JacketSeal feedthrough provides a water-tight seal between the electronics and the external environment. From submersible sensors to aerospace instrumentation, hermetic electrical assemblies become an important part of the design process to suit the environment in which the sensor operates.

How do I convert a helium leak rate to a water vapor leak rate?

Helium leak rate can be easily converted to a water vapor leak rate by using a 0.469 multiplication factor. To learn more about hermetic feedthroughs in being sealed from water vapor, download the whitepaper: Hermetic Feedthroughs Safeguard Mission-Critical Electronics

Are liquid-tight connectors and gas-tight connectors used in hazardous locations?

Yes. Liquid-tight connectors are commonly used to protect instrumentation and electronics from weather elements, submersion in fluids, and applications elements such as flooding. Gas-tight electrical connections such as wire bushings are commonly used in hazardous locations. The hermetic or gas-tight seal prevents the penetration of the gas into the instrumentation or electronics that can cause the ignition of the flammable liquid or gas. These types of seals are governed by third party approval agencies and standards. Douglas Electrical Components will work with you and your team to either design a custom liquid or gas-tight seal for your hazardous location file or offer a design from our hazardous area listing for explosion-proof areas.

How does JacketSeal compare to a compression seal?

Compression seals can leave gaps between the conductors in a feedthrough. This creates potential leak paths between conductors. JacketSeal creates a wire seal around the individual wire jackets. The epoxy bonds to nearly any conductor material and is expertly applied to ensure the proper sealing between conductors within the housing.

Our wire seals are tested mechanically and electrically for a proper seal and operation at our factory. It’s designed, sealed and ready for installation, creating a plug and play component. This saves your operators from compressing the fitting and testing its seal.

Can JacketSeal wire seals be designed to seal to the cable and conductor jackets?

Yes, Douglas can seal to the cable jacket (including materials such as Teflon and Tefzel) as well as to the conductor jackets. This protects and seals the feedthrough with an added layer of protection. Other design features can also be sealed including shielding and armor.

Image Library

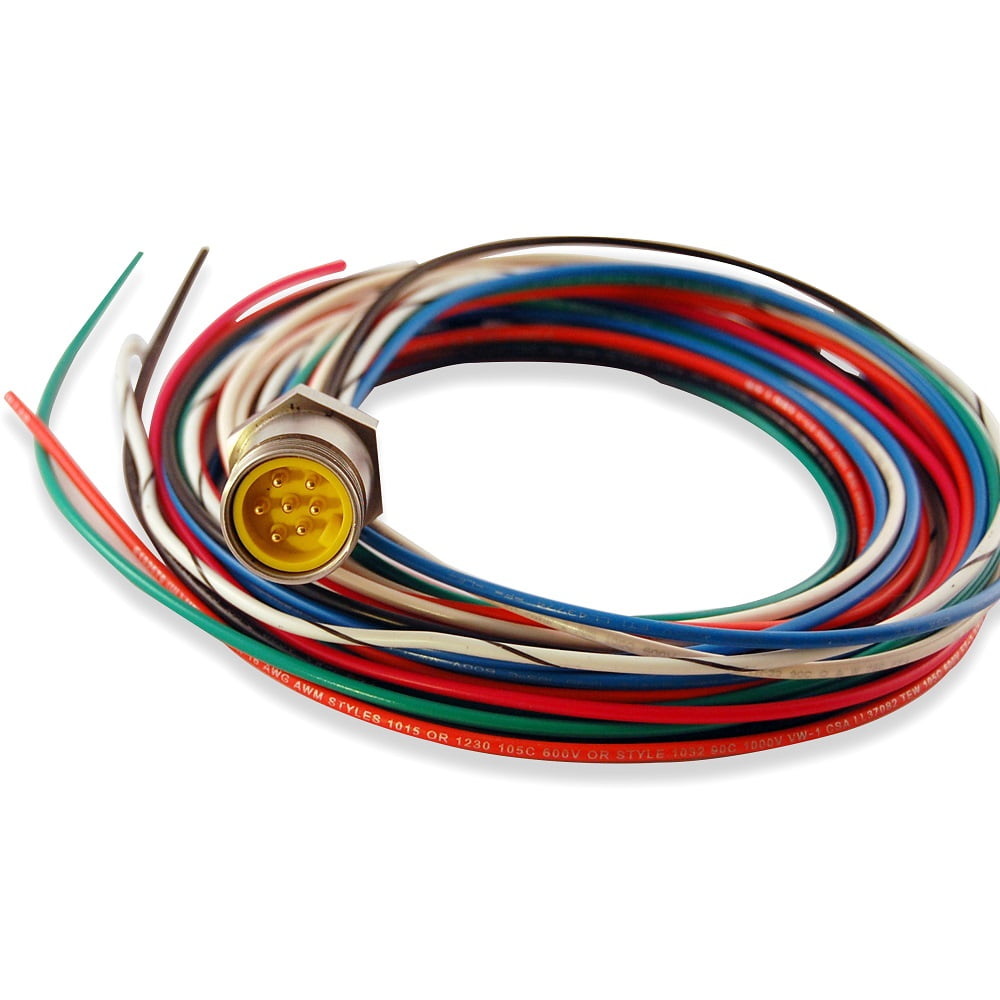

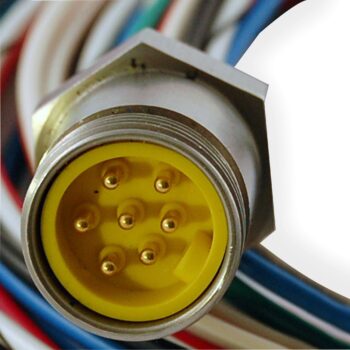

JacketSeal Connector to wire Assembly

JacketSeal waterproof and weather proof wire/cable connector assembly

Waterproof Push-Pull Connector Assembly

Waterproof connector assembly; seal non-hermetic connectors in cost effective packages with Douglas JacketSeal.

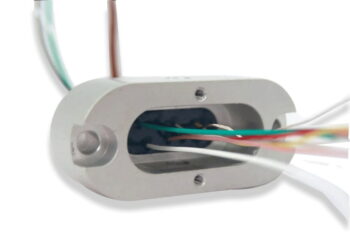

Sealed Feedthrough Assembly

Hybrid JacketSeal-DuctorSeal feedthroughs are used in applications requiring both true hermetic sealing and fluid blocking—such as this hybrid feedthrough that seals both the vacuum chamber and heat transfer fluid for a magnetic bearing flywheel.

JacketSeal Custom Flanged Feedthrough

Small gauge wires sealed in custom flange assembly

Water-tight Cable Harness Assembly

Integral circular connectors in harness meeting water-tight requirements.

Water-proof Cable Assembly

Water-proof cable assemblies available with custom integral connection options to retrofit existing wiring or meet new requirements.

Sealed MIL-spec Connector Harness

Customer-specific design with moisture-tight sealed connector ends

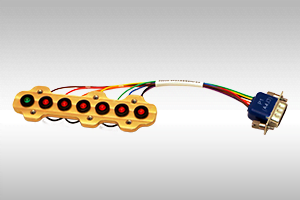

Custom LED hermetic wire harness assembly

DFM assembly simplifies installation while improving reliability.

Water-tight Fiber Assembly

Water-tight sealed fiber optic cable assembly

Hermetic Wire Power Feedthrough Connector

Hazardous area conduit seal assembly with integral connector

Water-proof industrial connector wire assembly

Water-proof industrial connector wire assembly

Water-proof industrial connector wire assembly

Water-proof industrial connector wire assembly

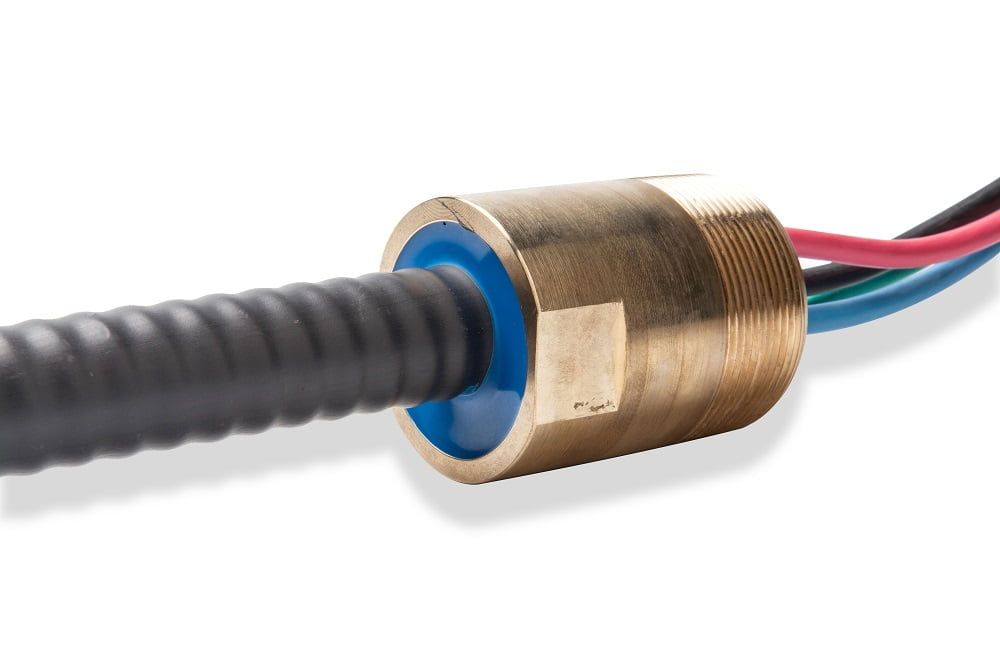

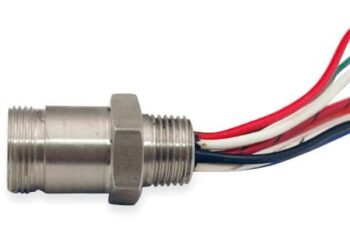

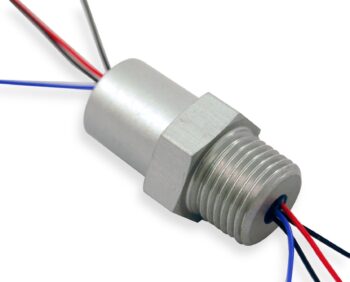

Explosion-proof NPT Conduit Seal

Explosion-proof NPT Conduit Seal with male and female threaded ends

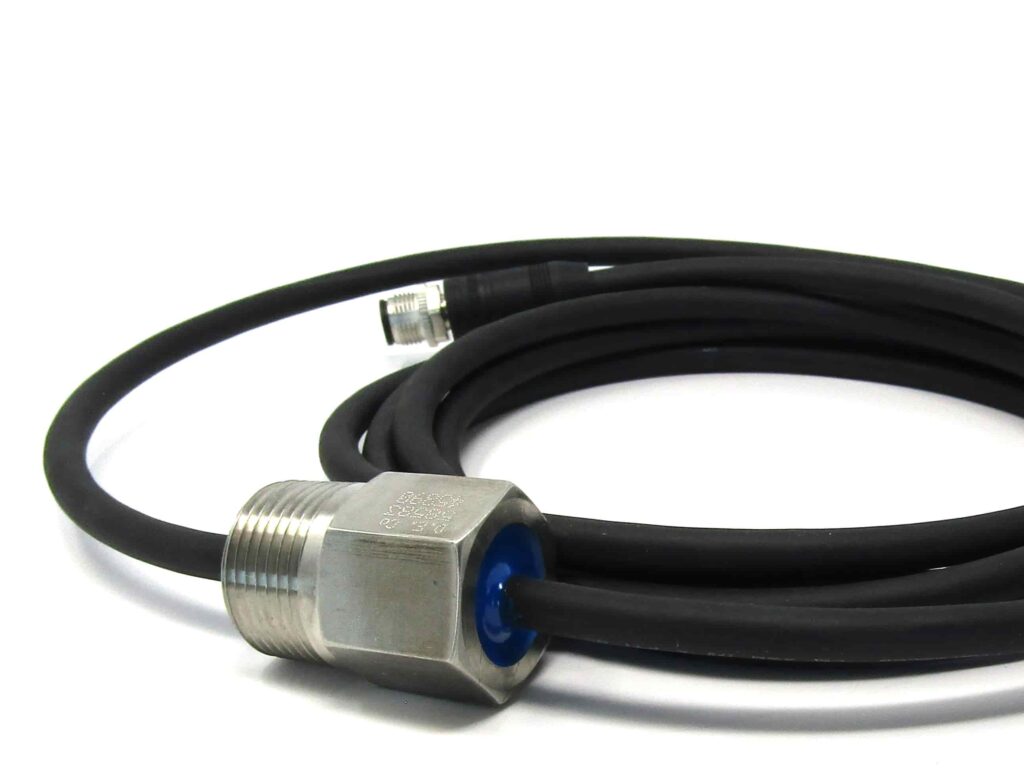

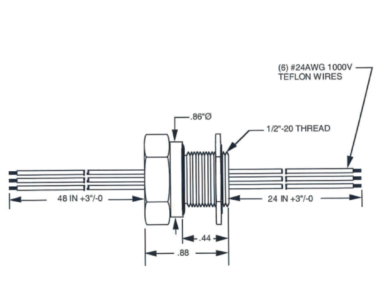

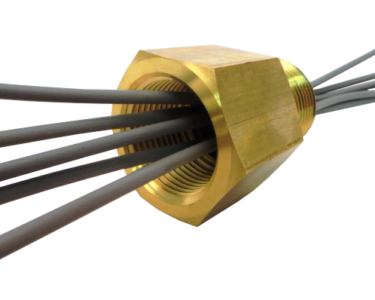

DuctorSeal NPT threaded explosion-proof cable seal

Standard NPT wire bushing for instrumentation and controls with explosion-proof rating

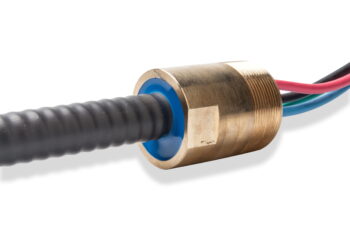

Explosion-proof conduit seal with cable to wire

Explosion-proof conduit seal with cable to wire. Various wire gauges and housing materials available to create the best combination of durability and price effectiveness.

Documents & Downloads

Literature

Whitepapers

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations