PTR Series Push-through Feedthroughs

Change electrical connections without breaking hermetic seals

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

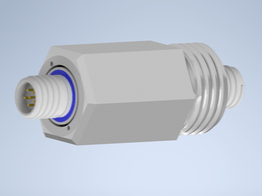

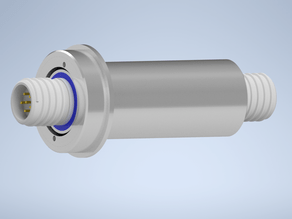

Douglas Electrical Components manufactures Push-Through Receptacle (PTR) hermetic assemblies for applications such as glovebox setups where the electrical connections are consistently changed and/or upgraded.

The hermetic insert is designed to provide a hermetic seal during use and replacement. Using four O-rings of Viton or Nitrile material, the insert and its replacement maintain the hermetic interface with the feedthrough housing, keeping the glovebox operator safe and isolated from the environment inside the glovebox. Inserts can be designed with a variety of electrical connections, with connectors being most common. A variety of standard MIL-spec connectors are available including MIL-DTL-38999, MIL-DTL-26462, and MIL-DTL-5015. Commercial connectors include 120V, 240V, RJ-45, USB-C, and USB 3.0. Non-standard options include circular connectors such as M12/M23, banana jacks, thermocouples, push-pull connectors, high voltage connectors, and high current/amperage connectors. Additionally, Douglas Electrical can integrate a variety of optical fiber connectors including ST, LC, and MTP.

Watch the video to learn more about how the PTR assembly can work for you.

There are three main mechanical interfaces for the glovebox wall or chamber called the feedthrough housing: NPT threaded connection, faceseal with jamnut, and weld-in assembly using 300-series stainless steel with MIL certifications as a standard. Custom designs and materials are available upon request.

Request a quotation for standard configurations or a custom design. Our made-to-order assemblies are typically available in 4-6 weeks with expedite options available.

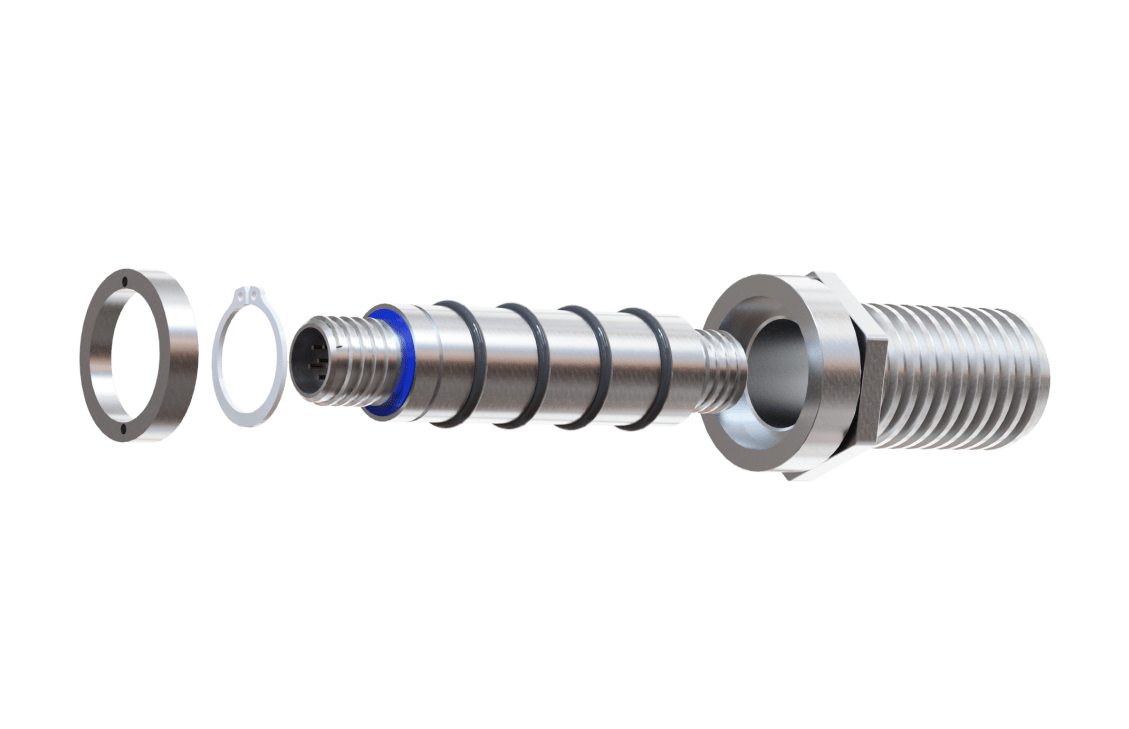

Vacuum Face Seal Design Example

Bulkhead Feedthrough Housing – Install the feedthrough housing directly into the bulkhead or glovebox opening.

Bulkhead Jam Nut – Used to secure the housing to the wall of the glovebox. An O-ring is compressed against the outside wall to create a hermetic seal. Jamnut torque specifications are thread specific.

Insert Housing – The insert is the replaceable hermetic push-through. Four O-ring seals are used to hermetically seal the feedthrough within the bulkhead housing, even during replacement and upgrades.

Hermetic Epoxy Seals – Douglas Electrical employs a chemically inert hermetic epoxy to seal virtually any type of electrical or fiber connection within the insert housing, creating high-density customized hermetic solutions.

Inside and Outside Connector – Customers can specify the connectors and/or wires required to meet their program needs.

Locking Nut – Douglas supplies a locking nut to hold the insert housing into the bulkhead feedthrough housing. The customer tightens the locking nut to secure the insert housing within the feedthrough housing.

Retaining Ring – The retaining ring keeps the insert housing from being pulled inside the system during install or operation.

Features

KEY BENEFITS

- Hermetic insert can be replaced during maintenance and upgrades without breaking the hermetic seal and thus contaminating the outside environment.

- Quick installation

- Feedthrough conductor options include connectors, wires, cables, and fibers

- Bulkhead housing options include O-ring face seals, weld-in, NPT, bolt on flange and custom

SPECIFICATIONS

Housing Material: 300-series stainless steel with MIL certs standard. Consult factory for other material options.

O-ring Materials: Viton, Nitrile standard; contact factory for other options.

Connector Feedthrough: Configuration Receptacle/Pin to Receptacle/socket standard on MIL-spec connectors; contact factory for other available options

Leak rate: 100% QC tested to <1×10-8cc He/sec. Contact factory for more options.

Voltage Rating: 100% QC tested to 600VAC or to design requirements

Pressure Rating: 100 PSI standard, higher pressures available upon request.

Operating temperature: -40°F to 225°F (-40°C to 107°C) Consult factory for expanded thermal range assemblies.

Radiation: Per AECL report, After exposure of radiation at a dose rate of 1.5 x 106 rad/hr, we were able to maintain a leakage rate of <1×10-8 cc-He/sec when we accumulated a total dose of 50Mrads (AECL 29-63174-300-000).

Flame Resistance: UL File No. E92366 rated UL-94HB; Also tested at White Sands by NASA: WSTF 79-11713, JSC #0945, NASA NHB 8060.1A. Passed. Self-extinguished and no ignition @ 130 amps on a #12 AWG wire.

Water Vapor Transmission:(Per ASTM E-96-80): 0.7 ±0.2 gms/m2 day, 0.125 mil sample thickness

ELECTRICAL CONNECTION OPTIONS

- Circular connectors including MIL-spec, metric, and

NEMA power - USB, RJ-45/CAT6, and Coaxial

- Fiber Optic

- High Voltage

CERTIFICATIONS & STANDARDS

- ITAR-DDTC

- DFARS

- ISO-9001:2015

- ISO-14001:2015

- Traceability and MIL certifications available

- IPC-620

- Tested in accordance with MIL-STD-810

ORDERING & DELIVERY

- Engineered and manufactured in the USA

- Made to order in 4 to 6 weeks

- Expedite options available

- Ongoing technical support

ACCESSORIES

- Mating connectors and harnesses

- Strain reliefs (right angle and straight)

- Protective connector caps

- Installation tool

- Retaining ring

- Locking nut

- O-rings (Viton and Nitrile standard)

FAQ

Are push-through assemblies available with different bulkhead fittings?

Yes. Douglas Electrical can customize the bulkhead housing to meet the size and installation method of your choice. Contact us today with the bulkhead option of your choice and we will determine if the other design requirements such as connector size and system pressure can meet the request.

What is the typical lead time for this type of assembly?

Lead time depends on a number of factors including material availability. In today’s environment, we work to ensure material is available based on the quoted lead time and at the best pricing. While our standard lead time is 6 weeks after acceptance of order, accommodations can be made for expedites in certain applications.

Are push-through assemblies available for pressure and vacuum applications?

Yes. These designs are available for pressure and vacuum rated systems. The retaining ring and locking nut design ensure the feedthrough remains in place while also protecting against pulling on the cables.

Documents

Documents & Downloads