Hermetically Sealed Mil-Spec Connectors Mil-Spec Connectors

Reliable, Custom-Sealed Mil-Spec Connectors for Extreme Environments

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

Reliable, Hermetically Sealed Mil-Spec Solutions for Extreme Environments

Military specifications, aka Mil-Spec connectors, are critical in applications and systems where failure is not an option. At Douglas Electrical Components, we specialize in custom-built, hermetically sealed Mil-Spec connectors engineered to perform reliably in the most demanding environments. These are a popular option for aerospace, defense, oil and gas, industrial, and vacuum-based applications.

High-Performance Mil-Spec Connector Feedthroughs Benefit Demanding Applications

Hermetically sealed MIL-Spec connectors create feedthroughs designed to ensure maximum performance and reliability in critical environments. While the Department of Defense requires the use of MIL-Spec connectors for military and defense, the standards also benefit outside manufacturers. Using standardized parts helps maximize quality, reliability, compatibility, and interoperability. With a focus on forward-thinking design, our MIL-Spec connectors deliver long-lasting dependability that can future-proof your most demanding applications.

Types of Mil-Spec Connectors We Offer

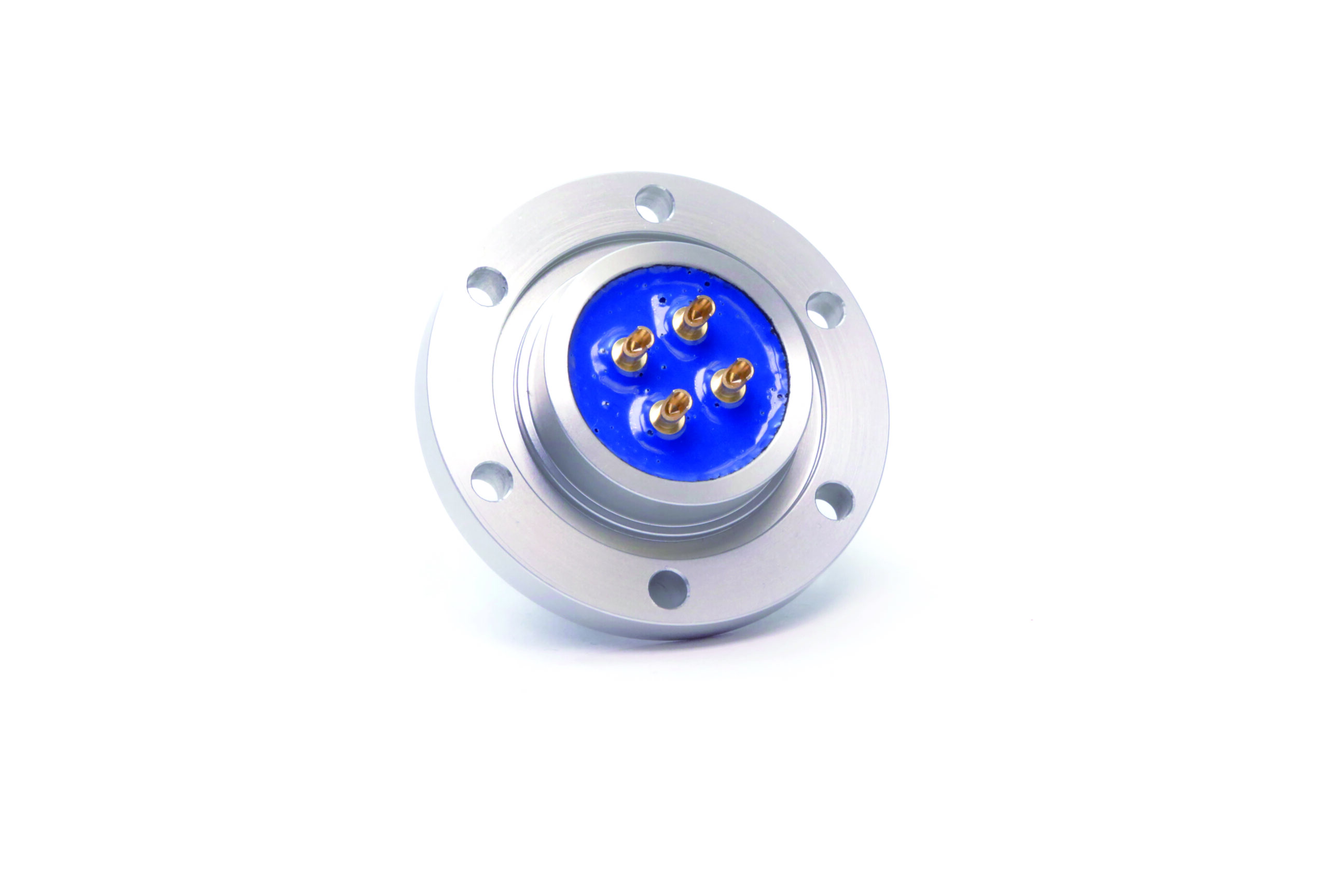

Transform standard connectors into fully hermetic MIL-spec solutions using Douglas’s proprietary low-outgassing epoxy sealing process. This creates the design flexibility to utilize any Mil-Spec electrical connector, each designed for specific applications and performance requirements.

Below are some of the MIL-SPEC connector types we commonly seal:

D-sub Connectors

Plug-and-play hermetic D-sub connector with reversible mounting.

Micro-D Connectors

Hermetic Micro-D connectors with fully reversible mounting for vacuum applications.

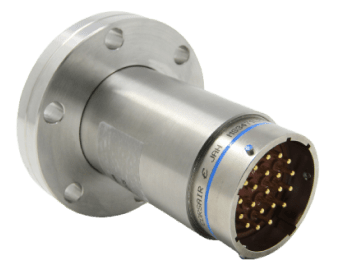

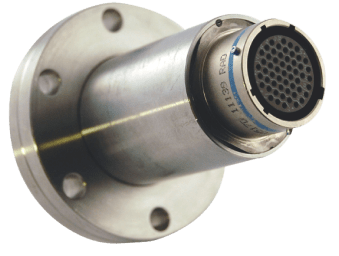

38999 Hermetic Connectors

Made-to-order hermetic MIL-DTL 38999 connectors and

assemblies available in less time than a "standard" 38999 hermetic connector.

MIL-DTL-26482 Hermetic Connectors

Customizable MIL-DTL-26482 connectors for versatile military and aerospace applications.

MIL-DTL-5015 Hermetic Connectors

Customizable MIL-DTL-5015 connectors for Harsh Environments.

MIL-DTL-26500 Hermetic Connector

We offer customizable hermetic MIL-DTL-26500 connectors that are built for harsh environments.

In addition, we provide custom hermetic sealing for other Mil-Spec connector types based on your specific needs. Our engineering team can develop a tailored hermetic solution to meet your exact performance and environmental requirements.

Key Features & Benefits of Our Mil-Spec Connectors

- Protects against moisture and dust, but creates a true hermetic seal to a standard leak rate of 1×10⁻9 atm-cc/sec.

- Choose a standard connector and customize it to the hermetic properties and mounting configuration you need

- Rugged and environmentally resistant designs, Available in various finishes and multiple pin options and configurations

- 4-6 Week lead team AAO (After Acceptance of Order); contact for expedited service

- Our connectors can withstand temperatures ranging from -40°F to 225°F, making them suitable for extreme environments.

- We offer customizable solutions, including material selection, terminations, and mounting options, to meet specific project needs.