MIL-DTL-26482 Hermetic Connectors

Customizable MIL-DTL-26482 connectors for versatile military and aerospace applications.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

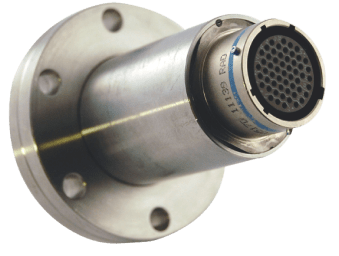

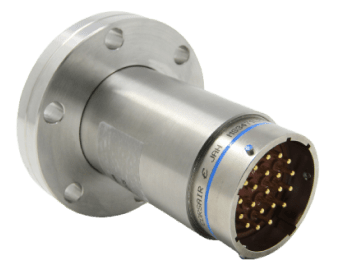

MIL-DTL-26482 Series I and Series II connectors, formerly MIL-C-26482, are two series of quick-disconnect miniature circular connectors with three-point bayonet coupling mechanisms used to connect systems requiring power and signal in military and defense environments. These connectors are designed to operate across a wide temperature range of -55°C to 150°C. Douglas Electrical Components provides MIL-DTL-26482 or MIL 26482 standard, series I and II hermetic connectors that ensure reliable performance in harsh environments where standard connectors may fail. They are suited for military and defense applications, vacuum chambers and commercial applications that require helium leak test rates less than 1×10-8 cc He /seconds.

Offered in smaller sizes than standard connectors, these MIL 26482 standard hermetic connectors feature a three-point bayonet coupling mechanism, with crimp rear insertable and releasable contacts, enabling quick mating and unmating. This bayonet coupling mechanism also makes it an ideal choice for applications located in hard-to-reach or difficult locations. We can provide these connectors in different mounting styles, including wide and narrow flange mounts and shell and contact sizes. It ensures complete flexibility in interconnect system design. In addition to crimped contacts, the MIL-DTL-26482 connectors have various contact styles, including solder and printed circuit boards. These contacts enable easy integration and termination to electronic subsystems and I/O cabling.

Unique Features of Douglas MIL-DTL-26482 Hermetic Connectors

Unique Features of Douglas’ MIL-DTL-26482 Hermetic Connectors

It is important to note a few more unique distinctions of Douglas capabilities with 26482 connectors.

- Douglas offers more design flexibility – convert virtually any non-hermetic 26842 connector into a hermetic connector design. While glass-to-metal seal connectors have a limited range of hermetic connector options, our technology permits us to hermetically seal all pin and shell sizes.

- Integrate a custom mechanical interface – Douglas can design and manufacture 26482 connectors with a customized mounting interface for vacuum and pressure applications. This can be as simple as a box mount design, threaded face seal or high-pressure radial O-ring feedthrough housing.

- Customized electrical interface – Design a standard pin interface, equivalent receptacle connector, or a completely custom electrical interface directly within the 26482 connector assembly. Douglas can integrate wires, cables, flex circuits and more to reduce footprint, weight, and complexity while increasing design robustness with the electrical interface encapsulated and hermetically sealed.

Features

MIL-DTL-26482 Hermetic Connectors Features

- Compliant with MIL-DTL-26482 for harsh environments

- Hermetic sealing rated at 1×10-8 cc/sec helium.

- Rugged and environmentally resistant designs

- Rear insertable / releasable contacts for quick mating and unmating

- Operating voltage to 1000 VAC (RMS) at sea level

- Rear insertable and releasable contacts ensure the safety of front

- Equipped with tear resistant grommets that can withstand wide range of chemicals or fluids and sealing over a wide range of wire diameters

- SAE AS39029 qualified contacts ensure durability and high performance in harsh environments

- Air-tight glass-to-metal seal makes it ideal for military and commercial defense and aerospace environments

- Available in various finishes and multiple pin options and configurations

- MIL-DTL-26482 Type hermetics are interchangeable with other bayonet connectors that meet MIL-DTL-26482

Featured Standard Products

FAQ

What is the difference between MIL-DTL-26482 series I and series II connectors?

Series I connectors feature scoop-proof solder contacts with bayonet coupling. Series II connectors have removable crimp contacts. It allows for a wide selection of end bells, including EMI shielding end bells.

Where are MIL-DTL-26482 Series I and II type hermetic seal connectors used?

These connectors are used in military and commercial applications, such as aircraft, vacuum chambers, marine equipment and ground vehicles.

What are common shell materials for MIL-DTL-26482 series I and series II connectors?

Series I connectors feature shells made from aluminum and tin-plated steel shells are used for series II connectors for standard applications. Black zinc nickel, olive drab cadmium, electroless nickel and black anodized nickel are some common shell materials for series 1 connectors used for military, defense and aerospace applications. Olive drab cadmium ensures excellent corrosion resistance and conductivity in challenging military environments. Black zinc nickel is often considered the best alternative to cadmium. It has excellent conductivity and corrosion resistance. Electroless nickel plating stands out due to its higher conductivity than cadmium, but it may not be corrosion-resistant.

What are the termination options available for MIL-DTL-26482 connectors?

Crimp terminations and solder cup terminations are available for these connectors. Both options ensure the same level of performance; however, crimp termination options are more preferred in military applications, such as rockets, launching missiles, and satellites due to their serviceability.