MIL-DTL-83513 Micro-D Connectors

Hermetic Micro-D connectors with fully reversible mounting for vacuum applications.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

As more instrumentation is added for testing and measurement, the need for miniaturization has increased. Micro-D connectors, designed for Mil-spec MIL-DTL-83513, have reduced the footprint of the electrical connection to accommodate the market demand. Douglas Electrical Components manufactures a standard product line of hermetic Micro-D connector feedthroughs for various applications. Our standard Micro-D feedthroughs create a plug-and-play electrical connection for vacuum systems. With Micro-D connectors on both sides of the feedthrough, engineers and system integrators save time and effort, eliminating the need for soldering miniature connector wires or solder cups. These MIL-DTL-83513 connectors are ideal for low leakage and high-pressure applications, where vibrations and size can be a concern.

Douglas incorporates Micro-D feedthroughs into various semi-custom and custom designs. From a standard CF or KF flange to a completely customized feedthrough plate assembly, we manufacture hermetic high-density solutions, including those with multiple micro d sub connectors within a single assembly.

Douglas can customize any conductor to make the electrical connection of the feedthrough. We can directly integrate wires, cables, pins, solder cups, or flex circuits directly into our hermetic epoxy. We can customize these hermetic Micro-D connectors with shielding and jacketing, labeling, and more to make a plug-and-play assembly.

Standard Vacuum Micro-D Feedthrough Connectors

Manufactured with a stainless-steel or aluminum housing, our hermetic Micro-D connector line seals are offered with a standard Viton+ O-ring; the housing is designed with O-ring grooves on either side of the housing to be fully reversible and simplify installation.

The feedthrough is designed with electroless nickel-plated aluminum shell connectors. The connectors are pinned straight through the housing, such that Pin 1 on the vacuum connector is fed to Socket 1 on the atmospheric side. The standard leak rate is < 1×10-9 cc He/sec with higher performance available. All standard Micro-D pin counts and connectors are available.

Features

- Plug-and-play with two connectors in a hermetic package

- Hermetically sealed and 100% tested

- Reversible design to increase mounting options

- 4-6 week lead time AAO (After Acceptance of Order); contact for expedited service

Specifications

| Housing material | Stainless-steel or aluminum | |

| Mounting bolt holes | 4x M3.0x5 0.335 full thread depth (bolts not included) | |

| Connector material | Electroless nickel plated aluminum shell | |

| Connector feedthrough configuration | Plug-to-Receptacle; both connector sides can be mounted in vacuum environment | |

| Feedthrough connection | Straight-through design; Pin 1 (vacuum) to

Socket 1 (atmosphere), standard |

|

| Leak rate | < 1×10-9 cc He/sec. Contact factory for more options. | |

| Operating temperature | -40°F to 225°F (-40°C to 107°C) | |

| Current rating | 3A per contact in air | |

| Voltage resistance | 600 VAC in air | |

Quality

- ISO9001 / 140001

- RoHS / REACH compliant

- <1×10-9 cc He/sec

Featured Products

Micro-D Connectors Configurations

View our standard Micro-D feedthrough configurations. For further customization, our team is ready to help tailor products to meet your needs.

| Product Name | Housing Material | Conductor Count | Vacuum Leak | Operating temperature | Electrical Hipot |

|---|---|---|---|---|---|

| 56273 – 37 Position Micro-D Feedthrough | Stainless-steel or aluminum | 37 | < 1×10-9 cc He/sec. Contact factory for more options. | -40°C to +225°F | 600 VAC |

| 56269 – 15 Position Micro-D Feedthrough | Stainless-steel or aluminum | 15 | < 1×10-9 cc He/sec. Contact factory for more options. | -40°C to +225°F | 600 VAC |

| 56268 9-Position Hermetic Micro-D Feedthrough | Stainless-steel or aluminum | 9 | < 1×10-9 cc He/sec. Contact factory for more options. | -40°C to +225°F | 600 VAC |

| 56275 100 Position Hermetic Micro-D Feedthrough | Stainless-steel or aluminum | 100 | < 1×10-9 cc He/sec. Contact factory for more options. | -40°C to +225°F | 600 VAC |

| 56269 15 Position Hermetic Micro-D Feedthrough | Stainless-steel or aluminum | 15 | < 1×10-9 cc He/sec. Contact factory for more options. | -40°C to +225°F | 600 VAC |

Image Library

Hermetic Micro-D Assembly

Hermetic micro-D connectors in AlBeMet plate for space-rated application

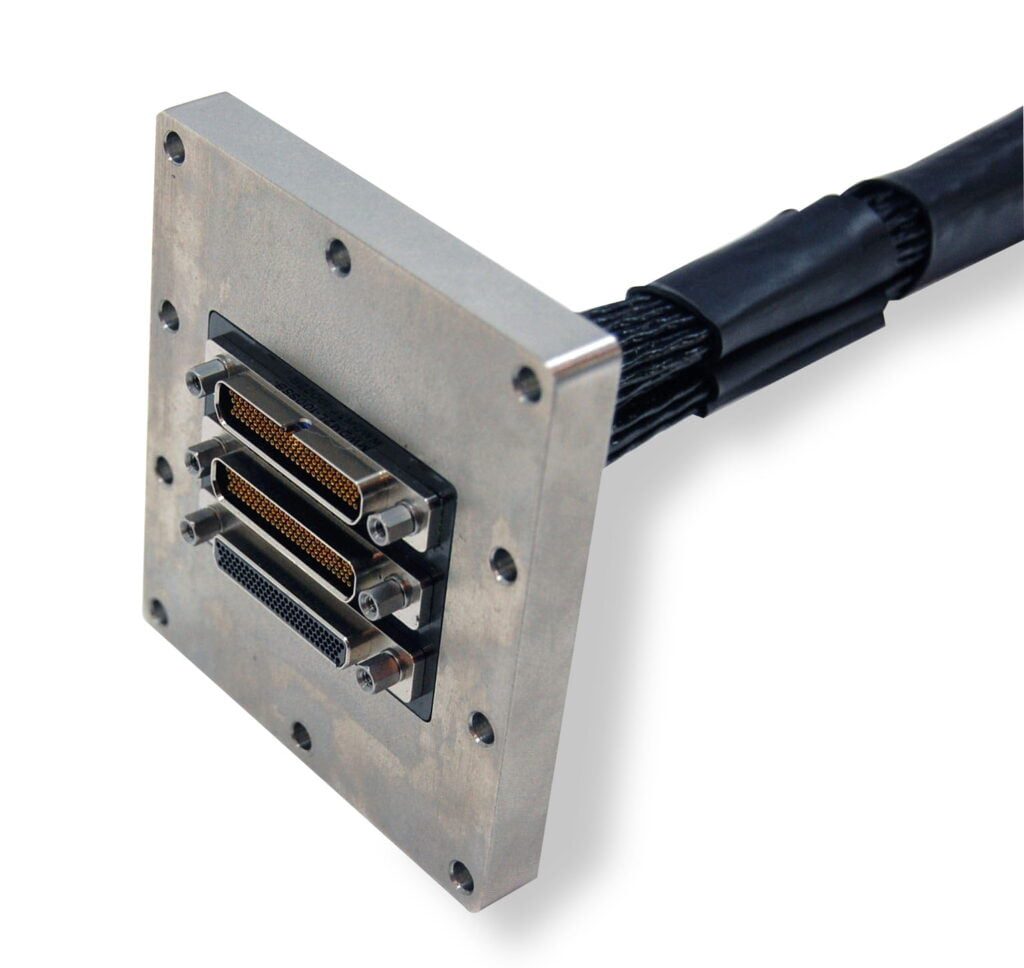

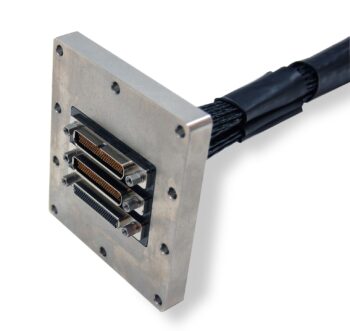

Micro-D hermetic feedthrough assembly

Micro-D hermetic feedthrough assembly with custom wire connection set up for drop-in installation.

Hermetic USB to Micro-B Feedthru

Hermetic USB to Micro-B hermetic feedthrough with custom housing

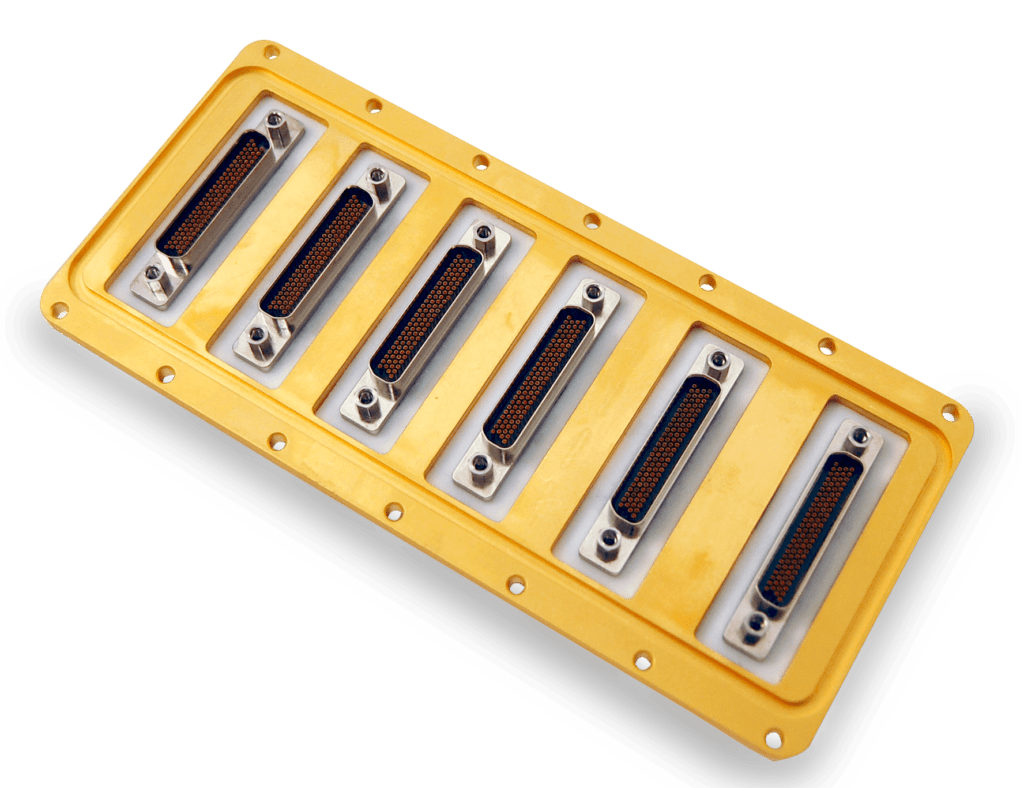

Micro-D Hermetic Portplate Assembly

Micro-D Hermetic assembly; customers can design multiple connectors within a PortPlate, custom design a solution, or choose a standard hermetic Micro-D feedthrough with reversible mounting

PBTR Micro-D Combination Feedthrough

Combine multiple connectors into a single mechanical interface

9 Position Micro-D Feedthru

9 position hermetic micro-D connector feedthrough

51 Position Hermetic Micro-D Feedthru

51 position hermetic micro-D connector feedthrough

56275-100 position hermetic micro-d feedthrough

100 position hermetic micro-d feedthrough

56288-hermetic-micro-d-9-pos-recept-front

9 position Hermetic Micro-D reversible hermetic feedthrough receptacle view

FAQ

What is a Micro-D connector?

A Micro-D connector is an electrical connector used to connect electronic devices or components. It is characterized by its small size and high-density configuration, which allows for a large number of contacts to be packed into a small space. Micro-D connectors are used in various applications, including military, aerospace, and medical devices.

A Micro-D connector is a combination of a male connector, also known as a plug, and a female connector, also known as a receptacle. These two components are designed to fit together, with the pins or contacts on the male connector mating with the corresponding sockets or contacts on the female connector. This connection allows the transmission of electrical signals or power between the connected devices or components.

What are the different types of Micro-D connectors?

Several types of Micro-D connectors are available, including standard, high-density, and high-speed connectors. Standard Micro-D connectors are designed for general-purpose applications and have a moderate density of contacts. High-density Micro-D connectors are designed for applications where space is limited and a large number of contacts are required. High-speed Micro-D connectors are designed for applications requiring high-speed data transmission and special features to improve signal integrity. Contact Douglas if you have specific requirements for the type of Micro-D connector you need to be integrated into a hermetic design.

Will Douglas Electrical customize a Micro-D feedthrough?

Yes. Douglas manufactures solutions in which a Micro-D feedthrough is installed into various machined ports and connectors of multiple sizes can be configured together. Douglas can choose from various materials with in-house CNC machining to support quick turnaround.

How do I install the Micro-D feedthrough?

The Micro-D feedthrough is supplied with an O-Ring gasket, which must be moved to the side installed against the cutout. The datasheet provides guidelines for panel cutouts.

What are the standard materials offered?

Stainless steel and aluminum are the standard materials available for the housing. Contact the factory for more options.

Do you offer a D-sub version of a MIL-DTL 83513 Micro-D Connector?

Yes. Use the following link to access it:

What is the difference between Micro-D and D-sub connectors?

Mil-Spec D-sub connectors and Micro-D connectors meet the stringent requirements of the US Department of Defense. Micro-D connectors comply with MIL-DTL-83513 standards and are smaller than D-sub connectors. These connectors are suited for applications with space limitations. They possess a high-density design, allowing more contacts than standard D-sub connectors. These connectors usually have 100 or more contacts, with a current carrying capacity of 1 Amp per contact, but offer the same robust connection as D-sub connectors. Our Mil-Spec Micro D-sub connectors are designed for high vacuum applications across military, aerospace, and high-speed electronics industries.

Mil-Spec D-sub connectors comply with MIL-DTL-24308 standards and are rectangular-shaped. These connectors feature a row of contacts in a metal shell. The design of these connectors contributes to quick mating and provides excellent EMC shielding. These connectors are usually used in legacy systems and equipment. They are available in standard and high-density configurations. Mil-Spec D-sub connectors may feature up to 50 contacts, whereas in high-density configurations, these connectors may have up to 74 contacts.

Mil-Spec Micro-D connectors offer better reliability in challenging work environments than Mil-Spec D-sub connectors.

Can hermetic Micro-D connectors handle high power and data demands?

Yes, hermetic Micro-D connectors can handle high data rates and support various power levels of your application.

Documents & Downloads

Datasheet