Custom Cable Harness Cable Harnesses

Wire and cable harnesses designed and manufactured to your specific requirements.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

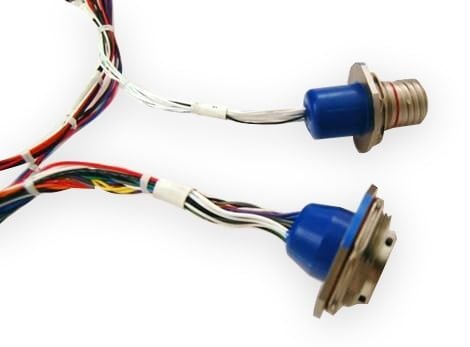

Douglas Electrical’s engineering team designs custom cable harness assemblies to industrial, hazardous area, and military standards, making them suitable for a wide range of applications and industries. Manufactured by IPC-620 certified technicians in our New Jersey facilities, our cable harnesses are tested to the highest quality and compliance standards. Each crimp, solder joint, and connection are handled with care. Harnesses and cable entry seals undergo 100% electrical testing before leaving our facility.

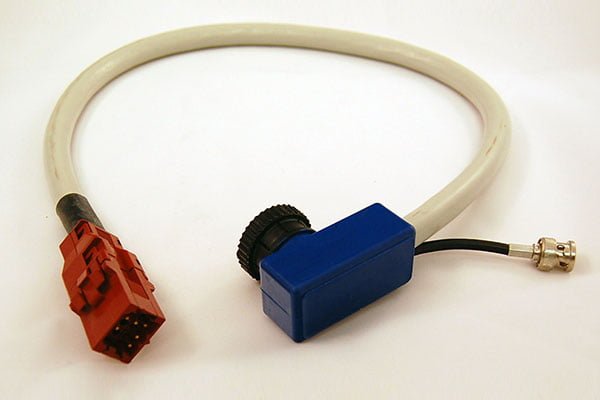

Incorporate the design elements specific to your requirements, including connectors, terminals, cable materials, and wire lengths. With an extensive portfolio of epoxy potting materials and over-molded rubbers, our cable harnesses satisfy industry requirements while addressing various technical needs, such as:

- High-voltage protection

- Explosion-proof sealing conforming to ATEX, UL, IEC, and CSA standards

- Ruggedizing in line with military and marine specifications

- Low outgassing suitable for vacuum use

Our Custom Cables and Wire Harness Assembly Solutions

Our hermetically sealed military cable harnesses can be designed to follow ITAR, DDTC, and DFARS requirements. Cable assemblies are also available for applications with RoHS, Conflict Mineral, and UL requirements.

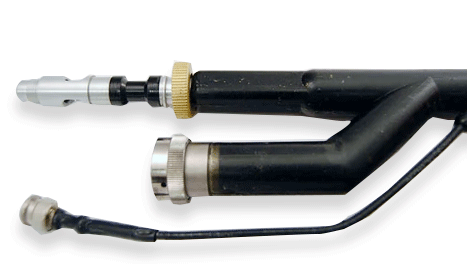

For Ultra-High Vacuum (UHV) applications, we manufacture cable harnesses and feedthroughs using our cutting-edge hermetic epoxy technology for sealing cables or wires through bulkheads with a mechanical interface. These UHV cable harnesses can be integrated for power, signal, or fiber applications.

Contact us today to learn more about our cable harness assemblies and other solutions.

Locate a Technical Sales Engineer

Features

MARKET CAPABILITIES

- ISO 9001:2015

- ISO 14001:2015

- ITAR DDTC Registration with DDTC and DFARS compliant assemblies

- IPC/WHMA-A-620 Certified Trainers and Application Specialists

- Hermetically and electrically tested assemblies

- UL 1203 Class I Division 1 Explosion-proof Groups A, B, C, D with ability to design to global IEC/ATEX standards

- RoHS Compliance

CABLE HARNESS TYPES

- Open wire harnesses

- Integral cable harnesses

- Braided harnesses

- Connectorized harnesses with integral back-potted connectors

- Integrated assemblies; as an example, design connector-to-wire harness assemblies for hermetic and non-hermetic applications

- Over molded hermetic cable assemblies

FAQ

What are different types of cable assemblies?

Douglas Electrical Components can customize the cable assembly or harness to meet your specific requirements. Cable assemblies can be manufactured to interface with a bulkhead connector or directly within a hermetic assembly. Our cable and wire assemblies can be designed for UHV or positive pressure applications using popular materials such as Kapton and Teflon (PTFE) (Dupont Trademarks).

Do you have minimum order quantities for a cable assembly?

We traditionally do not have minimum order quantities for our cable assemblies. Send us a copy of the drawing or send us your requirements for the cable assembly and we’ll can start the conversation.

Do you offer cable assemblies for hazardous locations?

Yes, Douglas Electrical Components can design and manufacture sealed feedthrough cable assemblies to be integrated into your device or system. While we offer some standard designs with threaded fittings, we can customize the wire, cable, connector, or fiber feedthrough to meet your requirements and certify the design.