BPC Series Hermetic Backpotted Connector

Industry-leading made-to-order hermetic bulkhead connector assemblies

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

Douglas Electrical Components offers hermetic, moisture-tight connector solutions through our BPC backpotted connector series. Standard commercial off-the-shelf (COTS) connectors can be converted to a hermetic design by backpotting the connector using our proprietary process. Douglas Electrical can also hermetically seal obsolete hermetic connector options for customers to maintain backwards compatibility, redesign a legacy product, or source a replacement. Our hermetically sealed connectors protect power and signal connections from environmental conditions. The enclosure contents and electronics are protected against liquids and gases from water vapor to fuels.

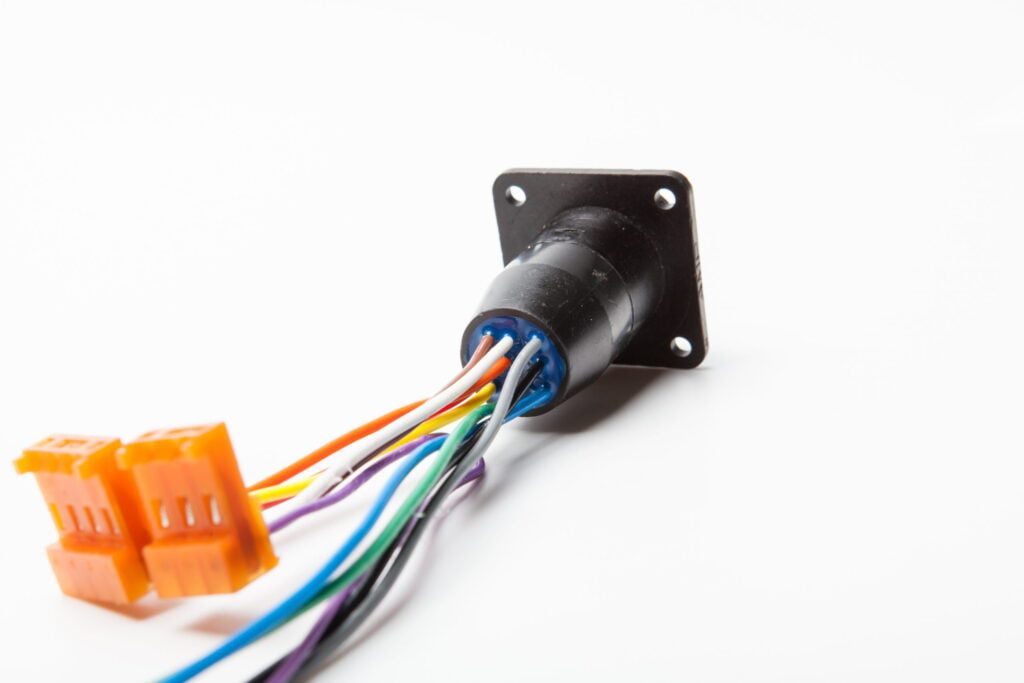

Directly integrate a variety of electrical connections including pins, wires, cables, optical fibers, flex circuits, and more. An added benefit to this electrical connection integration is the strain relief; the potting of the connector increases strain relief to prevent wires being pulled during installation and prevents voltage arcing.

Create prewired, turnkey assemblies for drop-in installation, increasing quality and reducing installation time. This can also consolidate the number of vendors to simplify design and supply chain management.

Reduce weight and size due to the combination of connector types and materials. Our hermetic epoxy will bond to a variety of connector materials including metals and plastics.

Locate a Technical Sales Engineer

Features

KEY BENEFITS

- Create hermetic, moisture-tight connectors from commercially available non-hermetic connector designs

- Plug-and-play drop-in assembly

- Seal the connector as-is, or integrate other mechanical and electrical features including optical fibers

- Increased availability by hermetically sealing non-hermetic connectors in stock or readily available versus hermetic connectors with long lead times

- Improve electrical insulation and shielding in certain applications

OPERATIONAL ADVANTAGES

- ISO 9001 / 14001

- ITAR/DFARS compliant

- Made in US

- LEAN manufacturing for cost competitive solutions

- Lead time

- Customization capabilities

COMMON CONNECTORS TYPES

- MIL-spec connectors

- Industrial circular connectors

- Push-pull connectors

- Obsolete hermetic connector designs

FAQ

What is the difference between a hermetic connector and sealed connector?

While the terms are frequently used interchangeably within the industry, a hermetic connector prevents the ingress of air, gasses, and liquids. It is typically specified with pressures from ultra-high vacuum to positive pressures. Sealed connectors can be hermetic but are typically more focused on the penetration of liquids. Sealed connectors are commonly specified with Ingress Protection (IP) ratings such as dust, submersions, and high-pressure wash down. We can design either hermetic or sealed connectors for bulkhead or standard connectivity. We specializing in converting non-hermetic connector options into a hermetically sealed interconnect.

Why would an application need a hermetic bulkhead connector?

It is critical to make sure your connections are gas tight throughout the life of the program. Without a hermetic seal in your critical application, you are vulnerable to moisture ingress, explosions, and other catastrophic failure modes. Hermetic bulkhead connectors allow for simplified installation to the wall of a chamber, cabinet, or system. While various bulkhead fittings are available, a traditional bulkhead feedthrough connector uses an O-ring face seal installation.

What is a bulkhead connector?

A bulkhead connector has electrical connections on two ends with the purpose of being fed through a hole within a panel and mounted. This allows for a sealed or fully hermetic electrical connection between the inside and outside of the panel, box, or system. The diameter of the hole within the panel is typically specific to the electrical connection to ensure the most suitable seal. Bulkhead connectors are designed with a variety of mounting types including flanges, threads, and plates, depending on variables such as the panel design, hermetic requirements, environmental conditions, and hazardous location certifications.

What is the default insert position?

All connectors have a default insert position “N”. Clockings A, B, C, D, X, Y, & Z.

What is the standard testing completed on PotCon connectors?

Standard performance specifications are below, yet we can customize our products to exceed the standards. Contact us to discuss the applications and requirements.

- Helium leak <1 x 10-9 cc-He/sec

- Vacuum levels to 1 x 10-8 Torr

- Assembly is hipot tested at 600VAC unless otherwise noted

- Temperature Range: -40°F to 250°F

What electrical connection types area available in a PotCon hermetic bulkhead connector?

Douglas electrical can customize the bulkhead feedthrough to feature a connector plug or receptacle on one end of the bulkhead connector and the other side featured as:

- Receptacle or plug

- Wire, cable, or fiber

- Printed circuit board (PCB) or flex circuit

- Pins or solder pins

Our website is a limited representation of our capabilities due to the variety and confidentiality we have in many of our hermetic bulkhead connector designs. Contact us today to review your application.

How do I configure and order accessories such as mating connectors?

PotCon Connectors, unassembled Mating Connectors, and Mating Harness-and-Connectors are all ordered as separate items. To order a PotCon Hermetic Connector: Specify the catalog number and add as a suffix a dash number, the length of the V side wire harness in feet, e.g.: a 24412-23 would be a 24412 PotCon with a 23-foot-long V side harness of 7 #16 AWG wires.

To order an unassembled Mating Connector: Prefix an A to the catalog number of the PotCon Connector you selected. Contacts are included at no charge.

To order a Mating Harness-and-Connector: Prefix either an A as above, then add as a suffix a dash number which will be the cable harness length in feet, e.g.: A24412-17 is an A side harness-and-connector with 17 feet of cable. Harnesses are provided fully assembled and tagged with the contact ID. Expandable braid of polyester will be placed over the A side harness. Wire conforms to MIL-W-16878E/5, 1000V, PTFE insulated, silver plated, stranded conductors.

A full line of optional designs and accessories are available for PotCon Connectors including hand crimp tooling, thermocouple alloy pins and sockets, alternate housing designs and sizes plus alternate insert arrangements.

What is a push-through assembly?

Douglas Electrical Components offers a unique design that allows customers to maintain the hermetic mounting within a glovebox or system with the design flexibility to change the electrical connection. The hermetic electrical connection is installed into the mechanical seal using multiple O-rings. This is common in applications where the types of bulkhead connectors change due to different equipment types used in a chamber or glovebox.

For more information, visit: Push-Through Feedthroughs

What is the difference between an PBTR and RBTR PotCon feedthrough?

The PBTR PotCon hermetic bulkhead feedthrough is a “plug” to receptacle design. The atmospheric side features a plug with pins and the vacuum side features receptacle/sockets.

The RBTR PotCon is a receptacle to receptacle design. The atmospheric side of the bulkhead is configured with a receptacle/pins and the vacuum/pressure side is a receptacle/socket configuration.

Does Douglas Electrical offer hermetic solutions for obsolete connectors?

Yes. Douglas Electrical can take non-hermetic connector configurations and hermetically seal the connector to replace an obsolete hermetic product such as the DM5623 connector series. Contact us for more information on our capabilities to hermetically seal as a backpotted connector or hermetic bulkhead connector solution.

Image Library

Backpotted BNC connector

Hermetic BNC-99 connector with integral wires

Backpotted jamnut connector harness

Industrial circular connector (M12) with jamnut mount and integral cable harness

Hermetic 38999 Wire Assembly

Hermetic MIL-DTL-38999 connector to wire assembly with O-ring seal rear view

Backpotted Connector to PCB contacts

Commercial off-the-shelf connector backpotted to hermetically seal the assembly with integral PCB pins

Hermetic USB 38999 Mil-Spec Backpotted Connector

Hermetic USB 38999 Mil-Spec Backpotted Connector

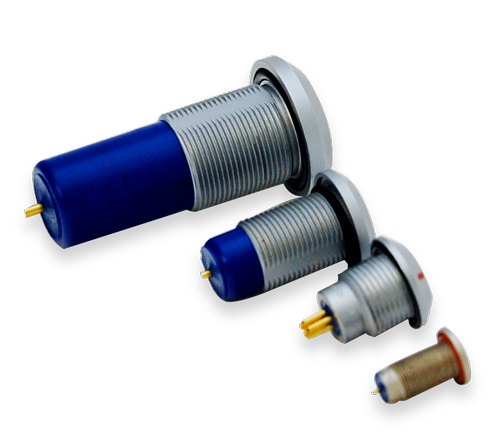

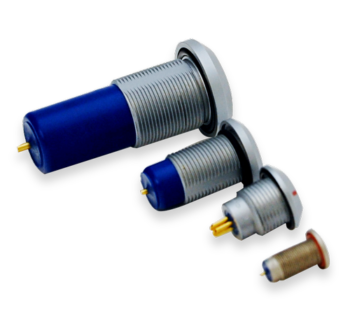

Push-pull Hermetic Connectors

Backpotted push-pull connectors for bulkhead mounting

Backpotted MIL-spec connector with integral PCB Pins

Backpotted MIL-spec connector with integral PCB Pins

Standard 38999 non-hermetic connector backpotted with integral wires

Standard 38999 non-hermetic connector backpotted with integral wires

Electrical MS connector

MIL-SPEC connector hermetically sealed assembly with integral wires

CircuitSeal Connector to board

Hermetically sealed MIL-spec connector directly integrated into printed circuit board (PCB)

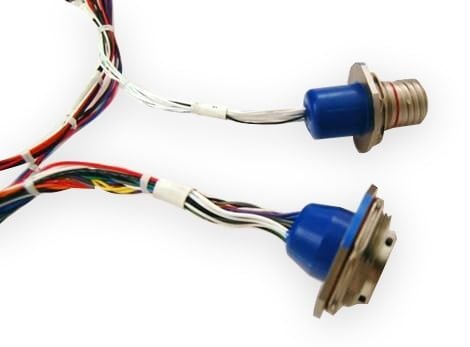

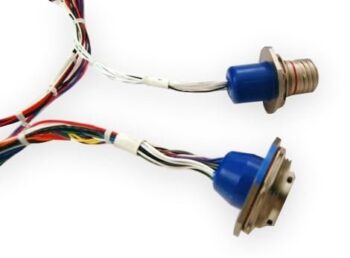

Integral Harness Backpotting Solutions

Create hermetic connector assemblies directly within your wire or cable harness assemblies

Hermetic RBTW optical fiber connectorized feedthru

OptiSeal RBTW MIL-spec connector-to-wire feedthrough creates a hermetic package with customer-specific wire

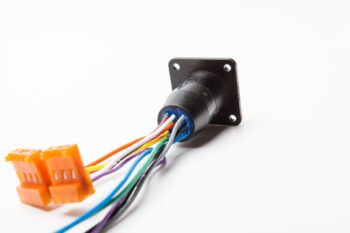

Custom Molded Hermetic Connectors

Create customized hermetic connector assemblies with plastic connectors and integral wires or cables

Hermetic Fiber Optic Connector

38999 backpotted fiber optic connector rear view

Hermetically sealed MIL-spec connector with integral pins

MIL-spec backpotted connectors for military, aerospace, industrial, and autosport applications.

Documents & Downloads

Downloads