Cryogenic Feedthroughs

Customized hermetic electrical feedthroughs designed for cryogenic systems.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

A cryogenic feedthrough is a specialized type of electrical connector that is used to transmit electrical signals or power through a cryogenic environment. A cryogenic environment is a type of low-temperature environment, typically at temperatures below -100°C, and is commonly used in scientific and industrial applications. Cryogenic feedthroughs are designed to maintain a reliable electrical connection between two devices or components while operating in a cryogenic environment. Devices operating in a cryogenic environment could include sensors, processors, and communication systems.

Douglas Electrical Components manufactures customized electrical feedthroughs for various types of cryogenic equipment and systems, from land-based to off-shore. Our hermetic epoxy ensures wires, terminals, cables, connectors, and fibers are hermetically sealed in the cryogenic environment. Hermetic epoxy allows for both design flexibility and high-density electrical connection points to minimize the number of feedthroughs in the cryogenic environment and thus potential leak paths. Our epoxy is rated for cryogenic temperatures.

Our design team has performed various tests under pressure and temperature cycles to ensure a hermetic bond between the electrical interface and mechanical housing, both in-house as well as third-party testing. A recent example tested a custom cryogenic feedthrough down to -320°F with 300 PSI for a 30 minute duration.

Flanges and housings are customizable to our customers’ exact specifications. From large diameter bolt-on flanges to threaded connections, our hermetic cryogenic feedthroughs can directly integrate into existing mechanical interfaces.

Our Technology

Hermetic sealing combines epoxy resin and a housing material such as stainless steel to encapsulate an electrical conductor such as a pin, stranded wire, or threaded stud. The conductor feeds through the opening with the epoxy curing to create a hermetic seal. Various types of epoxies can be used, which can yield varying results in hermetic performance, chemical compatibility, and outgassing. Our designs enable customers to increase signal density, mix conductor types, and integrate connectors and terminals for a hermetically sealed connection for power or signal.

Cryogenic Solutions

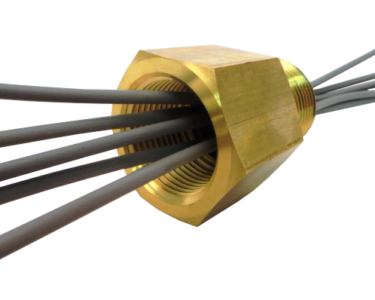

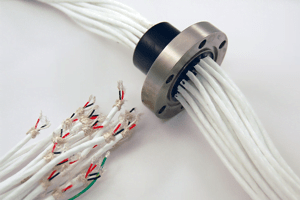

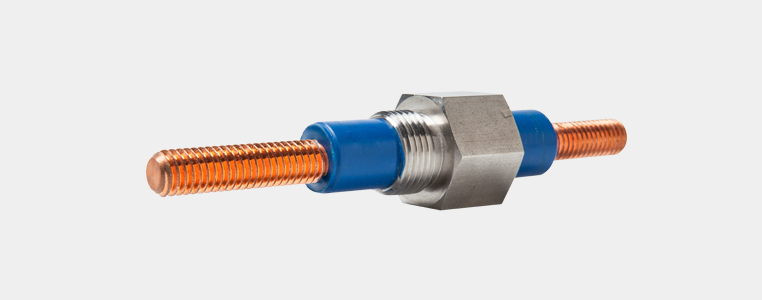

Cryogenic Wire Feedthru

Cryogenic wire feedthrough with JIC fitting allows for operation in high pressure and low temperatures.

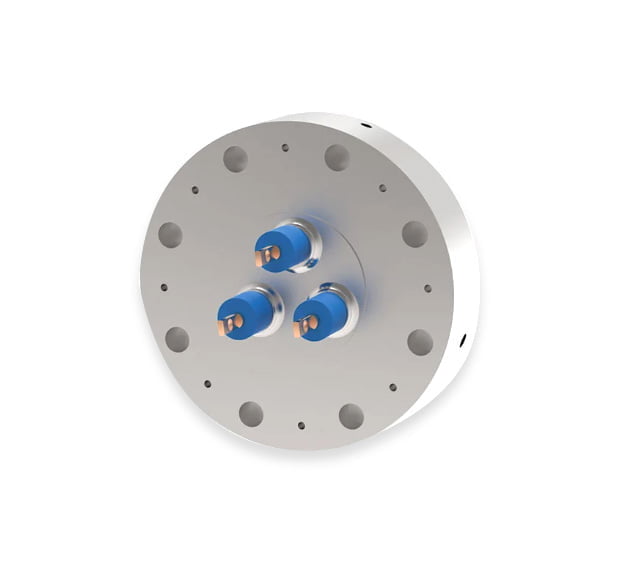

Cryogenic Power Feedthrough

Cryogenic Feedthrough design with three power feedthroughs integrated into a custom flange.

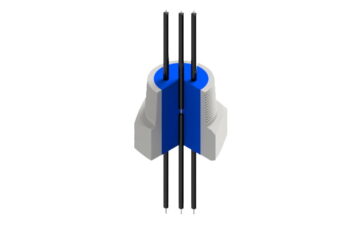

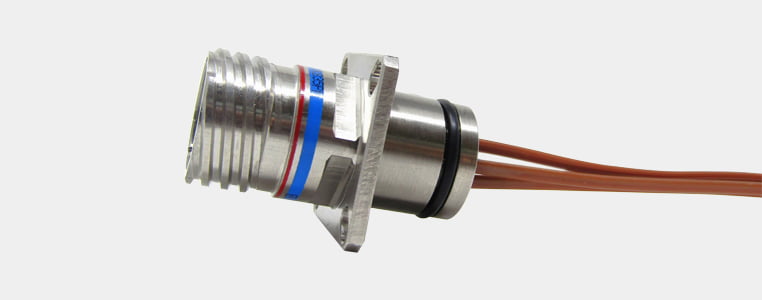

High Pressure Feedthrough Connector

Use connectorized hermetic feedthroughs for to simplify installation.

PotCon CF Hermetic Feedthrough

RBTW hermetic connector to thermocouple wire feedthrough with CF flange

Hermetic Coax Wire Feedthrough

Hermetic coaxial feedthrough with NPT threads and coaxial wires

Hermetic 38999 Wire Assembly

Hermetic MIL-DTL-38999 connector to wire assembly with O-ring seal rear view

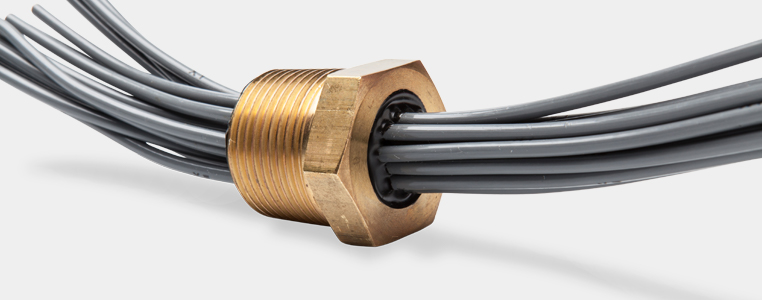

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

Sensor Hermetic Assembly

Hermetically sealed electrical feedthrough from PCB to cable in threaded housing

Explosion-proof Wire Bushing - Cable to Wire

Explosion-proof wire bushing seal; combine wires, cables, and connectors on either end of the bulkhead feedthrough fitting.

Hermetic assy - 3D

Hermetically seal your electrical feedthrough while customizing it to your exact needs.

Features

OPERATING CONDITIONS

- Operate up to 30,000V AC

- Hermetically seal against gases stored at cryogenic temperatures

TECHNICAL ADVANTAGES

- Directly integrate wires, cables, and terminals into a cryogenic environment without Coefficient of Thermal Expansion Challenges of other technologies

- Connect to wires, cables or connectors in the atmospheric environment for simplified system installation

- Create hermetic packages that meet global hazardous location standards including explosion-proof rated hermetic seals

- Create a high-density hermetic electrical feedthrough, minimizing feedthrough passages and potential leak points.

COMMON CONNECTION TYPES

- Wires and cables

- Thermocouple wires

- Studs and terminals

- Optical Fibers

- Connectors

APPLICATIONS

- Cryogenic storage tanks

- IoT monitoring equipment

- Transportation vehicles

- Off-shore Equipment

- Gloveboxes

- Medical equipment

Featured Products

Documents

Downloads

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations

Related Products

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Backpotted Connector Assembly

All the benefits of a hermetic connector with a custom mechanical interface.

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of

up to 1,000 amps and 15kV.

Custom Hermetic Flange & Plate Assemblies

Multi-port hermetic assemblies accommodate any feedthrough configuration,

with time and troubleshooting minimized.

Thermocouple Feedthroughs

Create a hermetic thermocouple feedthrough in the exact configuration you need.