In today’s demanding environments, reliable data transmission is critical. Douglas Electrical Components steps up with their innovative fiber optic feedthroughs, proven in both hazardous and non-hazardous applications. While optical fibers create many opportunities for data transmission, partnering with a manufacturer you can trust with the handling of delicate fibers is critical. This case study showcases a collaborative effort with a customer, leveraging Douglas’ expertise and LEAN manufacturing to create a high-density solution with remarkable features.

Key Features

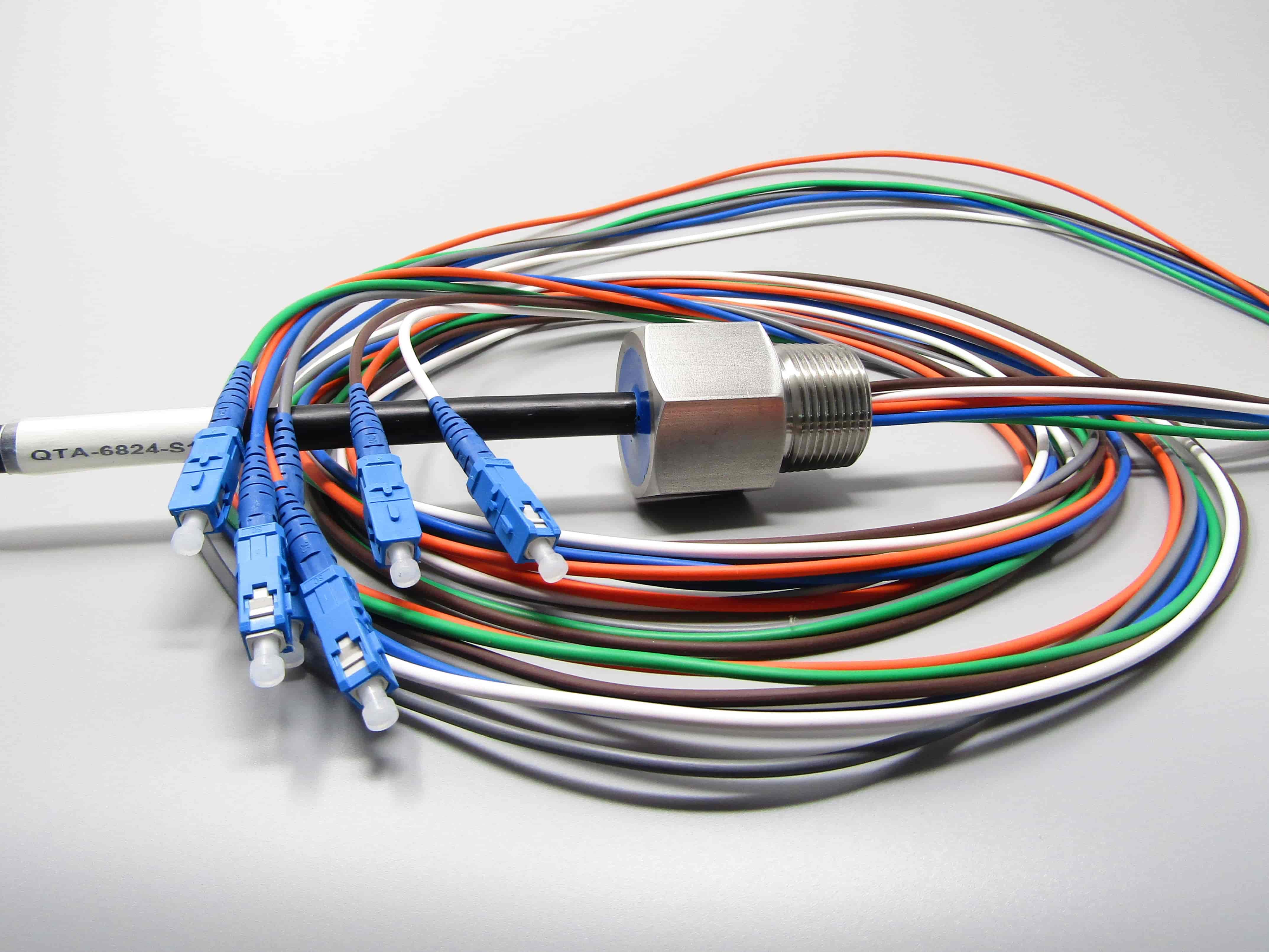

Densely Packed: Six individual optical fibers seamlessly integrated within a compact 1″ NPT stainless steel body, maximizing space utilization.

Cost-Effective: Stainless steel offers excellent corrosion resistance at a competitive price, ideal for various chemicals, water, fuels, and certain gases.

NPT Threading: This industry-standard interface provides a cost-effective and reliable connection for low to medium pressure applications.

Hermetic Sealing: Each fiber is encapsulated and hermetically sealed using a high-strength, chemically inert epoxy, guaranteeing 100% leakproof performance.

Easy Installation: Unique color-coded fibers and integral SC connectors simplify setup and minimize errors.

Environmental Protection: Sealed PE cable jacket shield the fibers and feedthrough assembly from liquids and gases, eve

n in fluctuating pressure, temperature, and humidity conditions.

Enhanced Durability: Shrink sleeve safeguards fiber ends, while clear labeling on cables eases organization and installation.

Expertise You Can Trust: Beyond this featured example, Douglas Electrical Components offers a vast range of fiber optic NPT feedthrough solutions. Their team of dedicated engineers is ready to collaborate with you to design the perfect feedthrough for your specific needs.

Key Industries

Glovebox: Test equipment is increasing the utilization of optical fibers due to their data transmission speed. Reliable seals between the glovebox wall ensure the glovebox environment remains isolated. Fiber feedthroughs are commonly specified with NPT threads as well as flanges.

Electrical Distribution: Optical fibers offer a high level of noise immunity commonly experienced in power distribution switchgear equipment. Douglas feedthroughs offer a cost-effective solution to transmit signals for OEM switchgear equipment. Fiber optic sensors can also replace traditional current sensors to measure equipment more accurately and with less signal loss.

Hazardous Locations: While hazardous locations is a broad industry term, optical fiber NPT feedthroughs can be specified from drilling to refining, including monitoring equipment, sensors, and controls. Partner with Douglas to certify a design to operate in hazardous locations while customizing to simplify installation.

Don’t settle for ordinary. Contact Douglas Electrical Components today and unlock the power of reliable, high-performance fiber optic feedthroughs!