The world’s demand for communications bandwidth continues to increase, driven by the rapid growth of cloud computing, the Internet of Things, wireless communication and other “big data” technologies. In these widely varying applications, traditional copper cables and connectors are no longer feasible. Today they frequently share a dependence on a robust fiber optic infrastructure to carry large volumes of data at ultra-fast transmission speeds. This trend is particularly noticeable in the defense industry, which is modernizing its complex communications systems by transitioning from copper in favor of fiber optics to support an array of cutting-edge equipment requiring faster data rates to perform navigation, combat, safety and damage control monitoring and other critical operations.

In addition to boasting data transmission rates much higher than possible with traditional copper lines, fiber optics offer several other benefits:

- They are impervious and immune to EMI (electromagnetic interference).

- Signal loss (attenuation) over long distances is very low.

- They exhibit exceptional signal security.

- Future bandwidth can be added without additional hardware.

As fiber optics prove vital to the operations of defense, energy and other essential industries, there has been a growing need to protect fiber optic infrastructure from damage. Moisture and other environmental conditions, in particular, can cause fiber optic equipment and the complex electronics required to process these optical signals to fail. One simple and effective way to protect these systems in land, sea, air and space environments is to make sure they are properly sealed against the environment with the help of hermetic epoxy-based sealing technologies.

Traditional Seals Limit Designers and Can Affect Optical Performance

While the need to properly seal fiber optic connection points is undeniable, not all seals are created equal. Many NEMA and IP-rated potted seals, grommets and cable glands can shield fiber optic components from water spray or temporary submersion at a limited depth, but they fall short of a moisture-tight hermetic seal and will allow gases and water vapor to transfer from the outside of a sealed system to the inside. An epoxy seal will resist environmental conditions such as shock and vibration or thermal cycles.

When it comes to achieving a hermetic seal for fiber optics, glass-to-metal seals are commonly used. However, they can place significant limitations on engineers customizing their assemblies to meet the needs of today’s fiber optic systems. They typically are only able to seal one or two fibers per fitting, and they are unable to seal directly to the cable fiber and therefore require two additional connection points at the seal bulkhead. Each fiber optic connection results in some data or speed reduction due to insertion loss.

As connection points are added to an assembly, designers risk exceeding their tolerance for these optical losses. Another limiting factor of glass-metal hermetic seals is the inherent manufacturing constraints that prevent designers from using many fiber optic raw materials, connectors and product configurations that proliferate today.

Benefits of Epoxy-based Hermetic Sealing

Epoxy-based hermetic fiber optic seals free designers from those well documented limitations. They provide the reliable seal critical applications need without affecting cable performance over time, even during vibration and through large temperature swings. Because epoxy sealing technology is highly adaptable, designers can achieve a custom hermetic fiber optic seal no matter the cable construction, configuration or jacket the assembly requires.

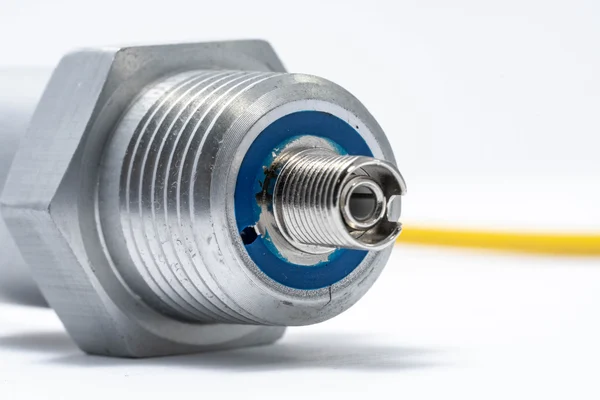

Douglas Electrical Components has decades of experience and expertise protecting critical fiber optic designs through its OptiSeal™ epoxy-based hermetic sealing technology. The line consists of two main products:

- PotCon® feedthroughs provide an optical connection point right at the bulkhead using common connector types such as LC, FC, MT, SC, SMC, SMA, ST and more.

- Cabled OptiSeal creates a hermetic seal directly to fiber cables without the need for bulkhead interconnect points. The hermetic seal can be applied to single mode, multimode, ribbon, outdoor rated, armored, mixed copper/glass and polarized fibers. Connectorization, cable breakouts and other cable harnessing options are available to support turnkey customer install.

OptiSeal epoxy fiber optic feedthroughs and connectors are 100 percent hermetically tested to stringent performance requirements to ensure the highest quality. The products have been validated for operation up to 8,000 psi and exhibit vacuum leak rates less than 1 x 10-9 cc-He/sec while maximizing data transfer rates. OptiSeal products also undergo extensive insertion loss and reflection loss testing before shipment, and they have been proven to provide reliable long-term sealing without adversely affecting data quality or speed.

And unlike glass-metal hermetic seals, epoxy-based hermetic fiber optic seals give designers the flexibility to choose any configuration they want for their seal. Instead of implementing a single connector on just one side of the seal, designers could for example have bulkhead connectors on either side of the seal or one side of the seal with fiber extending from the other. They can even send the fiber cable all the way through the assembly with custom lengths on either side of the bulkhead. This versatility reduces the amount of connection points in an assembly that could otherwise impact optical performance, and it gives designers the freedom to create the exact system they need to fit

their requirements.

In order to be qualified for use in military applications, hermetic fiber optic feedthroughs and connectors pass rigorous environmental tests including vibration and mechanical shock testing, salt fog tests, explosive (or burst pressure testing) and thermal cycle testing for their ability to withstand a variety of harsh environmental conditions in accordance with MIL-STD-810. After decades of qualification testing for countless customer designs and configurations, these criteria have not affected the optical performance or the hermetic seal of OptiSeal products. In addition to their exceptional test performance, they exceed the IP-69 ingress protection rating and NEMA 6P ratings for submersion.

Unlike glass-metal hermetic seals, epoxy-based hermetic fiber optic seals give designers the flexibility to choose any configuration they want for their seal.

More Than Just Military

In addition to their use in military applications, epoxy-based hermetic fiber optic seals also perform in:

- Semiconductor manufacturing inside a vacuum chamber where extremely expensive wafers are produced.

- Glove box applications commonly use complex hybrid fiber and traditional copper conductor cables in their equipment, which must be sealed to prevent hazardous materials from escaping their chambers.

- Network communication distribution. With the proliferation of fiber optic broadband networks, equipment in flood-prone areas require hermetic sealing. Additionally, immersion cooling feedthroughs are gaining in popularity due to the industry growth to cool servers.

- Hazardous locations and explosion-proof applications where solutions must be rated by ATEX, IEC, FM, UL and/or CSA to withstand environments where explosive gases can be present such as hydrogen-filled power generators and hydrocarbon processing facilities.

- Space simulation. By definition these chambers require hermetic solutions, and Douglas has worked with its vendors to develop fiber and connector options that reduce vacuum outgassing seen in common fiber optic cables.

- Military communications equipment. Because weight and size are always factors, installations demand dense cabling to achieve their desired performance. OptiSeal can seal cables that go above and beyond 100 fibers.

Implementing Epoxy-Hermetic Fiber Optic Sealing

Epoxy-based hermetic sealing technology is particularly suitable for fiber because no two fiber optic cable installations are the same. Any combination of optical components is possible. For instance, a feedthrough harness can contain a mixture of copper wires, fiber optic cables, thermocouples, power cables, shielded pairs, triplets and quads. Building the optimal assembly involves just a few selections:

- Select a housing/fitting. OptiSeal can be integrated into nearly all of Douglas’ standard and custom housing designs.

- Select a cable. Examples of cable types include but are not limited to simplex, duplex, MT ribbonized cables, patch cable, hybrid optical/electrical cables, outdoor and armored. Sealed cables can be grouped without having to allocate fiber legs based on connector pin sizes, counts, insert arrangements, polarization and clocking.

Select the optical fiber you want. OptiSeal can handle a diversity of fiber configurations such as simplex, duplex, ribbon and multifiber bundles. Spectral transmission ranges include UV/DUV, Visible, NIR, SWIR, MWIR, LWIR and FIR/THz for both single mode (single-index/monomode) and multimode (step-index and graded-index) applications. Cladding and core materials include glass, polymer and photonic crystal. Specialty fibers such as polarized maintaining fibers can also be processed. Coatings include but are not limited to Acrylate, PEEK and Polyimide. Commercially available external protective jackets can be processed as well as armored jackets for direct burial. Hybrid optical/electrical cables are also offered. Sealed cables can be grouped without having to allocate fiber legs based on connector pin sizes, counts, insert arrangements, polarization and clocking.

Select the connector you want. PotCon feedthroughs can accommodate connector types including LC, FC, MT, SC, SMC, SMA, ST and more.

Based on these criteria, Douglas Electrical Components can configure and build the right fiber optic seal assembly to meet your needs, saving design time and effort. You’ll not only get the assurance that comes from a 100 percent tested and proven hermetic seal for your fiber optic cable installation without affecting optical performance, you’ll also get the peace of mind that comes with partnering with a company that has decades of expertise protecting critical fiber optic applications.

Accept No Limitations For Your Fiber Optic Seal

Because fiber optics must handle the ever-growing need for high bandwidth in critical applications, designers cannot accept limitations in the seals that protect the connections. They can’t be limited by a seal that isn’t truly hermetic, and they can’t be limited by a seal that adversely affects optical performance. They also do not want to be limited by a hermetic seal that can’t accommodate many of the cables, fibers and connection types they must use to fulfill their design obligations. OptiSeal products from Douglas Electrical Components provide a complete hermetic seal for fiber optic applications, and their epoxy technology is highly adaptable to meet any customer requirement. The result: a secure, reliable seal for fiber optic applications without limitations.

Featured Hermetic Epoxy Seals

To locate a Douglas Electrical Components technical sales engineer in your area, please select a country. If your location is in the U.S., enter your 5-digit postal zip code.