Vacuum Freeze Dryers & Lyophilizer Feedthroughs

Maintain the desired chamber environment with our custom electrical feedthroughs.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

Overview

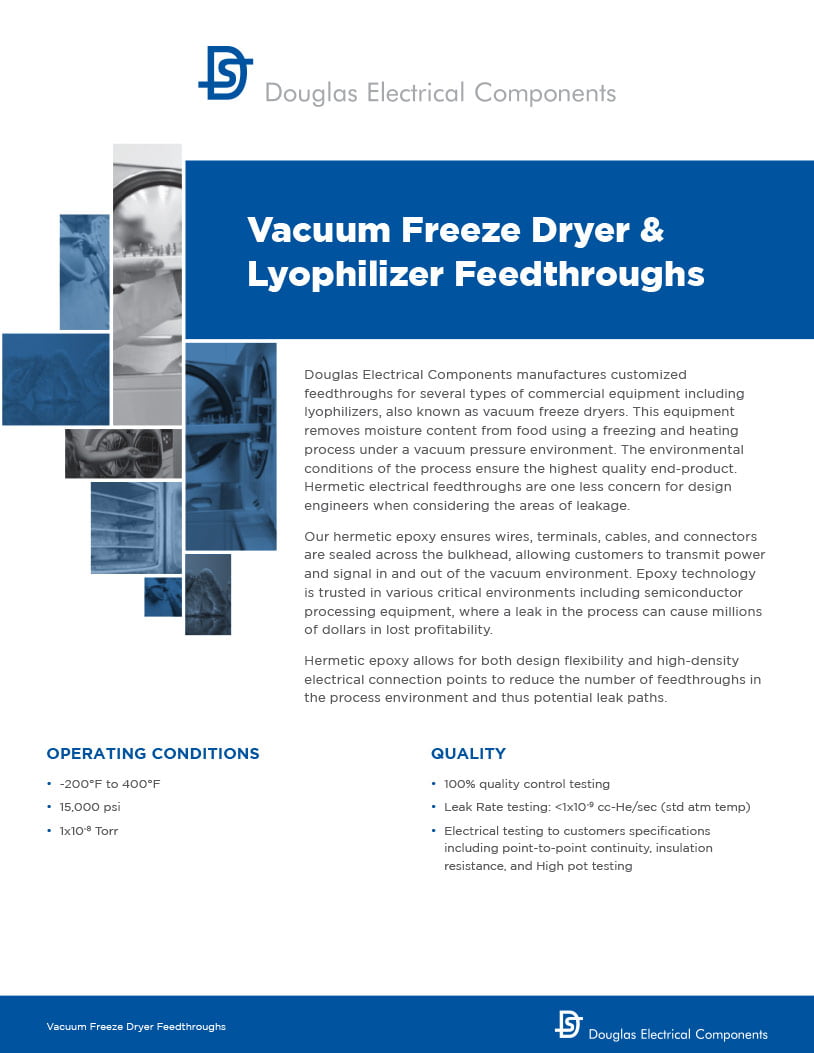

Douglas Electrical Components manufactures customized feedthroughs for several types of commercial equipment including lyophilizers, also known as vacuum freeze dryers. This equipment removes moisture content from food using a freezing and heating process under a vacuum pressure environment. The environmental conditions of the process ensure the highest quality end-product. Hermetic electrical feedthroughs are one less concern for design engineers when considering the areas of leakage. Our hermetic epoxy ensures wires, terminals, cables, and connectors are sealed across the bulkhead, allowing customers to transmit power and signal in and out of the vacuum environment. Epoxy technology is trusted in various critical environments including semiconductor processing equipment, where a leak in the process can cause millions of dollars in lost profitability. Hermetic epoxy allows for both design flexibility and high-density electrical connection points to reduce the number of feedthroughs in the process environment and thus potential leak paths.

Our hermetic electrical feedthroughs maintain the desired environment (vacuum pressure, temperature, and humidity) through the freezing, drying, and absorption processes.

Epoxy Technology

Our epoxy is rated for beyond the standard operating temperatures of lyophilizer equipment. The Douglas design team has performed various tests under pressure and temperature cycles to ensure a hermetic bond between the electrical interface and mechanical housing in harsh conditions including cryogenic temperature environments.

Electrical Connections

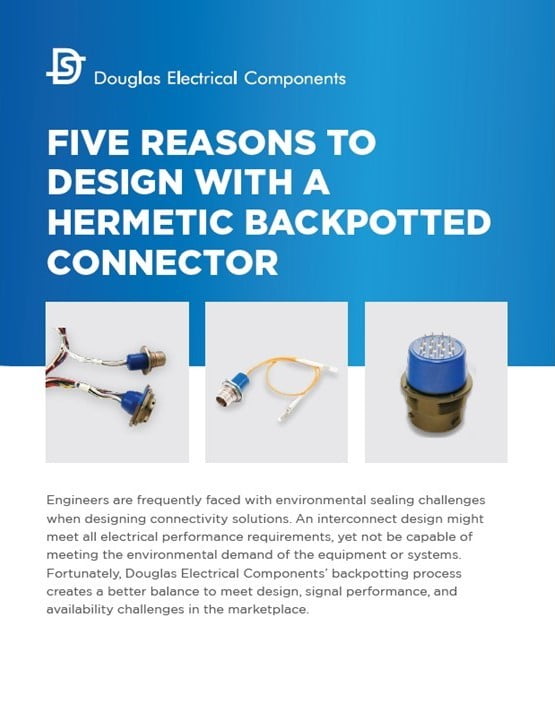

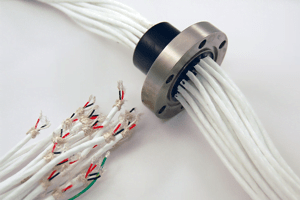

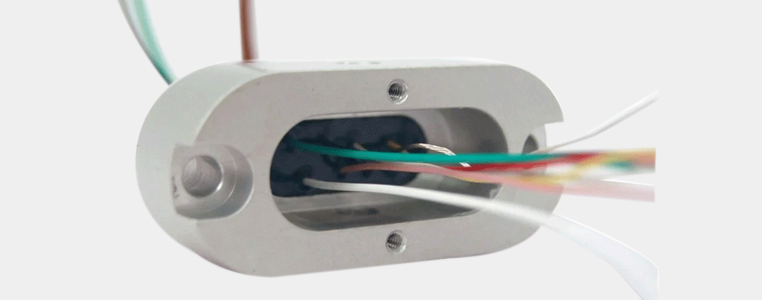

Various electrical connection types are available through the portfolio. For OEM equipment, customers traditionally utilize a connector-to-wire configuration. The connector receptacle is typically installed in the ambient environment with a direct wire connection within the vacuum environment. Various connector types are available including circular connectors like M8, M12, and M23. Douglas can hermetically seal virtually any non-hermetic connector within bulkhead assembly or as a back-potted connector. Wire-to-wire and cable feedthroughs are also popular with integral connectors at each end. Integrate thermocouple wires and connectors directly into the hermetic feedthrough for accurate temperature monitoring of the chamber.

Mechanical Interfaces

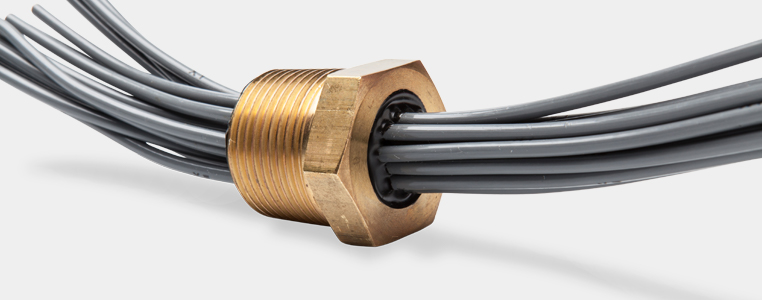

Various mechanical interfaces are possible including vacuum face seals. The mechanical design traditionally includes an O-ring to seal against the face of the bulkhead and a male thread long enough to both penetrate the bulkhead and leave enough room for sealing. The feedthrough is then installed by tightening a jamnut onto the threaded feedthrough and against the bulkhead to compress the O-ring on the interior wall. Vacuum flanges such as QF and CF flanges are available in standard sizes. NPT Feedthroughs are also a simple, common mechanical interface for customers to design into their systems. Thermocouple feedthroughs and power stud feedthroughs are commonly specified with NPT mechanical interfaces. Douglas can also customize the mechanical interface mechanical interface for other thread and installation types. With in-house CNC machining, we can meet customer quality, cost, and lead time demands.

Locate a Technical Sales Engineer

Features

Operating Conditions

- -200°F to 400°F

- 15,000 psi

- 1×10-8 Torr

Quality

- 100% quality control testing

- Leak Rate testing: <1×10-9 cc-He/sec (std atm temp)

- Electrical testing to customers specifications including point-to-point continuity, insulation resistance, and High pot testing

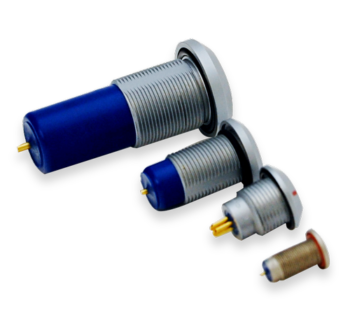

Product Image Gallery

High temperature RTW hermetic connector assembly

High temperature RTW hermetic connector assembly

hermetic wire high power feedthrough connector

Hermetic wire high power feedthrough in a connector-to-wire configuration for simpler integration.

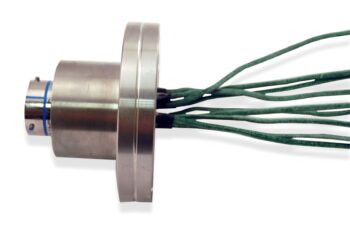

PotCon CF Hermetic Feedthrough

RBTW hermetic connector to thermocouple wire feedthrough with CF flange

Traditional PotCon Assembly

Hermetic bulkhead thermocouple MIL-spec connector assembly with vacuum face seal

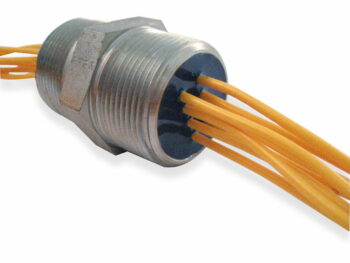

RBTW Waterproof Connector with NPT and wire leads

RBTW designed for environments that are submerged in water/liquid

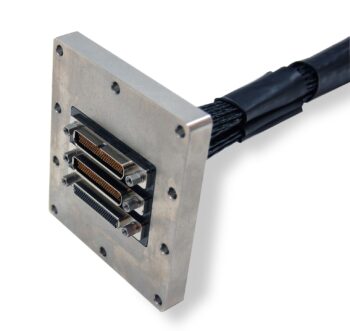

Micro-D hermetic feedthrough assembly

Micro-D hermetic feedthrough assembly with custom wire connection set up for drop-in installation.

CF Feedthrough DuctorSeal

DuctorSeal CF flange hermetic wire feedthrough for vacuum applications.

Turnkey Terminated NPT Cable Feedthrough.

Designed for plug-and-play application

Sealed Vacuum Fiber Optic Feedthrough

OptiSeal Fiber Optic feedthroughs can be provided in cable or connector-based styles.

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

Hermetic 38999 Assembly Side View

Create a customized hermetic seal for pressure applications

Backpotted jamnut connector harness

Industrial circular connector (M12) with jamnut mount and integral cable harness

Push-pull Hermetic Connectors

Backpotted push-pull connectors for bulkhead mounting

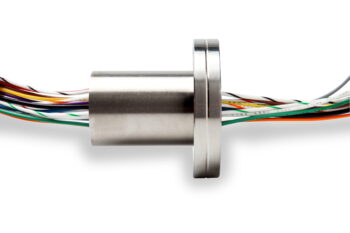

Hermetic Circular Connector

PotCon industrial circular metric connector with integral wires

Electrical MS connector

MIL-SPEC connector hermetically sealed assembly with integral wires

Documents

Literature

Whitepapers

Certificates & Standards

Related Products

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

Liquid Tight Wire / Cable Feedthrough Seals

Create a high-density, sealed wire or cable electrical feedthrough

for use in hazardous and/or non-hazardous areas.

Cable Harnesses

Wire and cable harnesses designed and manufactured to your specific requirements.

Contact Us