Oil transformers use liquids to act as an insulator and coolant within the system. The environmental and hazard impact of oil is of greater risk than gas insulators yet is still commonly used in various applications. Various liquid insulators are used in the industry from mineral oil to more environmentally friendly ester-based dielectric fluid. The liquid itself requires high dielectric strength with low degeneration. It can be used in a static housing environment or circulated and cooled naturally or through pumps. Over time, oil will degrade, creating the opportunity for harmful gases to be exposed to the atmosphere.

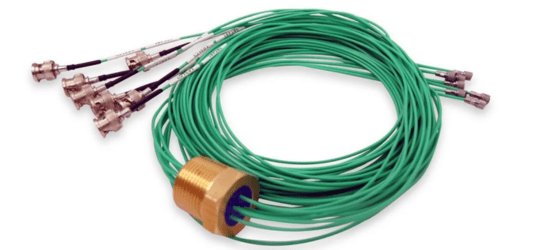

Advanced Wire Seals for Better Electrical Protection

Douglas Electrical Components manufactures hermetic wire feedthroughs that create a high density, customized seal for wires to penetrate the housing. The feedthrough housing can be designed with simple NPT threads with the seal rated for vacuum and positive pressures. There is also the flexibility to customize the housing using other materials and mechanical interfaces such as radial O-ring seals or bulkhead fittings.

Hermetic electrical feedthroughs create the opportunity to transmit power and signal in, out, or within transformer equipment.

Connector-to-wire feedthroughs with integral connectors create a customer-ready assembly; customers save manufacturing time, increase quality, and simplify field service. While oil transformers are typically a simple wire feedthrough assembly, other equipment such as network protectors benefit from connectorized assemblies in the design and install. In addition to hermetic wires, hermetic, water-tight connectors can help protect electronics exposed to any weather conditions.

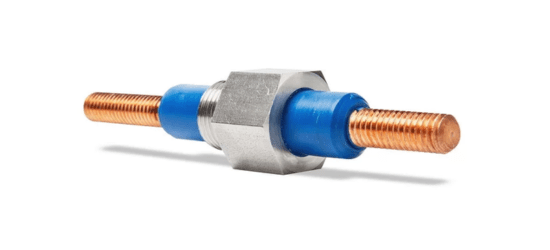

Customized Power Transmission Feedthroughs for High-Voltage Applications

For power transmission, Douglas Electrical Components manufactures feedthroughs with various customized configurations including threaded copper studs with flanged housings and heavy gauge wires. Standard power feedthroughs operate at 15kV, with custom designs up to 30kV. These StudSeal hermetic terminal seals are installed individually or mounted using our PortPlate design. As an example, the feedthrough assembly can create a simplified installation of studs to transfer power within the transformer assembly from the coil to the main tap changer. The housing, fittings, and configuration are all customizable to customer specifications to simplify installation and create a long-term solution for the life of the transformer.

The Role of Hermetic Seals in Sensor-Based Condition Monitoring

Douglas also manufactures hermetic seals for sensors and instrumentation used in the dissolved gas analysis of the oil. The IoT condition monitoring industry is increasing in value given increased government regulations to ensure safety and equipment condition. By monitoring the oil and gas conditions of the oil transformer, customers can trend the breakdown voltage of the transformer oil for predictive maintenance. Douglas Electrical Components hermetically seals the sensing elements of various condition monitoring sensors to ensure the sensing element is exposed to the oil and gas yet protects the electronics within the sensor’s housing. Our hermetic bond between the housing, epoxy, and conductor is trusted to hermetically seal applications such as hydrogen storage, the simplest atom.

Features

Operating Conditions

- -200°F to 400°F

- 15,000 psi

- 1×10-8 Torr

- Chemical/Oil/Fuel/Gas/Radiation compatibility is excellent

Quality

- 100% quality control testing

- Leak Rate testing: <1×10-9 scc He/sec (standard atm temp)

- Electrical testing to customer specification

- Point to point continuity

- Insulation Resistance, Hipot testing