Aerospace & Defense

We design and seal robust, hermetic solutions for land, sea, air, and space.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

Military and aerospace systems and equipment face environmental challenges beyond where standard connectors and wires can take them. Douglas Electrical Components manufactures hermetic and environmentally sealed feedthroughs with a broad range of connectivity capabilities. Our hermetic portfolio can seal wires, cables, connectors, optical fibers, circuit boards, or some combination thereof with the opportunity to reduce weight and simplify designs. Our epoxy technology creates a hermetic, water-proof seal capable of protecting electronics from water, water vapor, and a variety of other liquids and gases in a range of equipment on land, sea, and air including vehicles, missiles, and weapons.

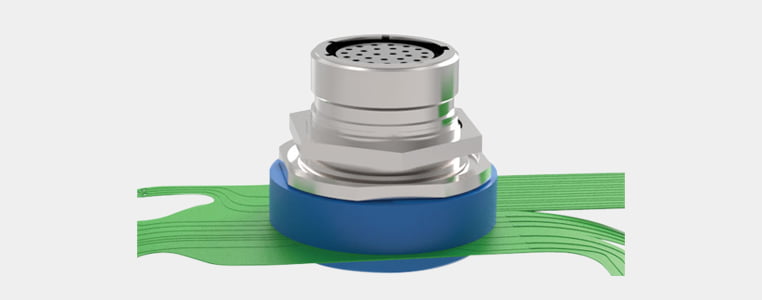

Hermetic Connectors

Military and aerospace connectors are specialized connectors that are designed for use in the aerospace industry. They are used to connect electrical and electronic components in aircraft, spacecraft, and other types of aerospace systems. Aerospace connectors are typically characterized by their high performance, reliability, and durability, as they are required to withstand harsh environments and meet stringent safety and quality standards. MIL/Aero connectors are highly reliable and durable, with a long operating life and low failure rate, making them suitable for use in critical applications. They are also resistant to harsh environments and able to withstand extreme temperatures, vibration, and other types of stress. In addition, aerospace connectors are designed to meet stringent safety and quality standards, making them suitable for use in highly regulated industries such as aerospace.

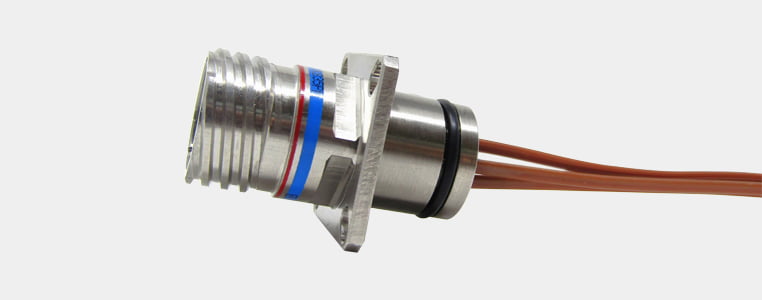

A hermetic aerospace connector is a specialized connector that is designed for use in aerospace applications where it is important to maintain a hermetic seal. A hermetic seal is a barrier that prevents the exchange of gases or liquids between the inside and outside of an enclosure, and is often used to protect components or devices from external factors such as moisture, dust, or contamination.

At Douglas Electrical, we convert non-hermetic MIL/Aero connectors into hermetic connectors and connector assemblies. We create lightweight, plug-and-play assemblies with a customer focus in mind. Our combination of LEAN manufacturing and Design for Manufacturability (DFM) creates unique hermetic solutions for customers.

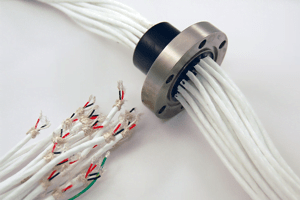

Hermetic Wires & Circuits

Douglas Electrical integrates various wire and cable types to create a hermetic seal. From bulkhead feedthroughs to integral hermetic connectors in wire and cable harnesses, Douglas will design a customized hermetic solution to meet customer demands. Our designs are used for both power and signal applications, with a wide range of liquid and gas compatibility. Some challenging media applications include fuels, cryogenic gases, and marine environments. Douglas also offers the unique ability to hermetically seal at the circuit level, including PCB’s, flex circuits and more. This can be critical in applications where the electronics of a device need added protection, such as a moisture tight environment with space constraints. Through our OptiSeal product line, Douglas will seal optical fibers through a bulkhead fitting or within an optical fiber connector, again, creating a hermetic plug-and-play solution.

Hermetic Solutions

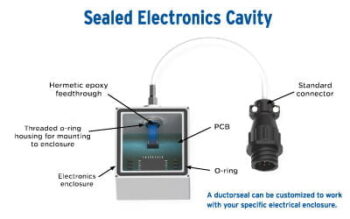

Our epoxy technology creates a hermetic, water-proof seal capable of protecting electronics from water, water vapor, and a variety of other liquids and gases. Additionally, a hermetic seal can be used to keep fluids within a cavity or system such as a fuel pump. Our technology creates a great amount of design flexibility to hermetically seal connectors, wires/cables, pins, and optical fibers.

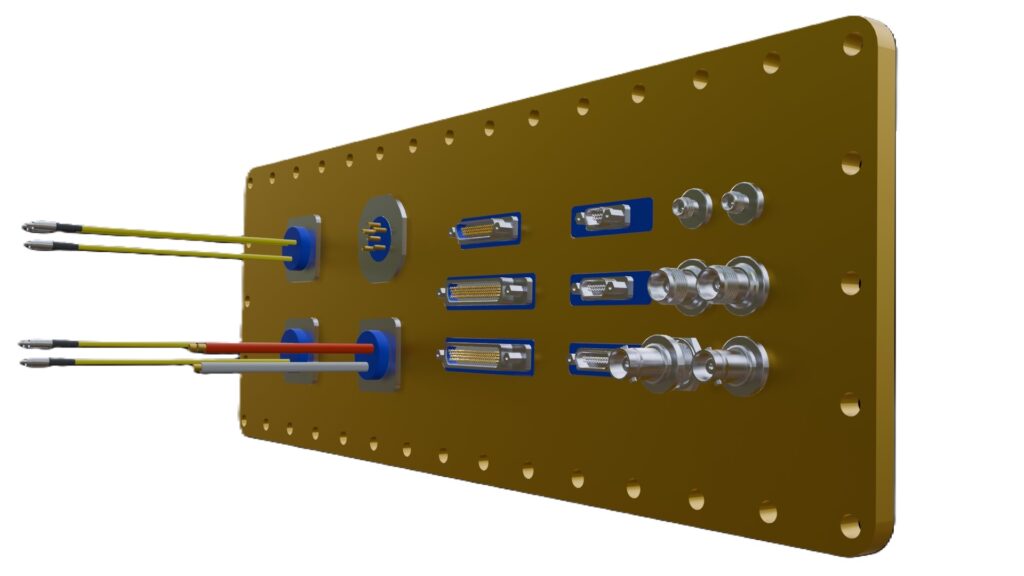

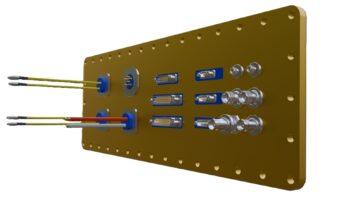

In addition to individual hermetic feedthroughs, we offer the PortPlate Series, which combine multiple hermetic interconnects into a single plate assembly, commonly used in military and aerospace applications. These fully assembled, pre-tested multi-port flange and plate assemblies can accommodate any feedthrough configuration. PortPlate systems can be customized to your needs, integrating electrical and mechanical connections into a ready-to-install hermetic solution.

Designed and manufactured in the US, Douglas Electrical can design and manufacture using COTS (Commercial Off-the-Shelf) components as well as support ITAR (International Traffic in Arms Regulations) regulated assemblies through design, tooling, certification, and testing. Our technologies allow the use of a variety of materials and connection types to create lightweight, high-density hermetic electrical connections. Our team of IPC-certified cable harness technicians assemble high quality assemblies, creating plug-and-play solutions in a wide range of production volumes. Our team can provide the basic hermetic seal and cable harness work like labeling, bundling, twisting, shielding, filtering, solder, and crimping.

Features

WHY CHOOSE DOUGLAS

- Build More – Buy Less – Create high density hermetic solutions using our proprietary epoxy technology to create an air- and moisture-tight seal of virtually any conductor, circuit, or optical fiber.

- Get it Faster – From rapid prototypes to full scale production, Douglas Electrical Components manufactures standard and custom solutions for MIL/Aero applications in our NJ facilities on schedule.

- Plug & Play – With a Design for Manufacturability mindset and technology with ultimate design flexibility, our application engineers will partner with you to design a hermetic solution as a second source or new design to optimize it for your operational success. Save time and money with Douglas Electrical Components.

TECHNICAL ADVANTAGES

- ITAR-, DDTC-, DFARS-, Conflict Materials-, and ROHS-compliant assemblies.

- AS9102 First Article Inspections available upon request; contact factory.

- Transform standard non-hermetic connectors into hermetically sealed assemblies.

- Electrically and hermetically tested to ensure quality.

- IPC-620 certified technicians provide the basic hermetic seal and cable harness work like labeling, bundling, twisting, shielding, filtering, solder, and crimping.

- Chemically compatible with a variety of liquids and gases

- Choose from mechanical interface materials including MIL-certified stainless steel, brass, plated steel, or lightweight options of aluminum, titanium, and plastics

- Use a variety or combination of wire and cable materials, wire conductor types, gauges, and lengths

- Integrate hermetic seals directly into active sensing elements, circuit boards, and flex circuits to save weight and space

VALUE ADDED CAPABILITIES

- Connectorized wire and cable feedthrough assemblies

- Full cable harnessing with hermetic properties for turn-key installation including braided or spiral shielding

- Directly integrate existing connectors, wires, cables, and termination boxes

- Hermetically sealing of customer-furnished mechanical and electrical connections

- Bundle mating cables, assemblies, and harnesses to reduce suppliers

EXAMPLE APPLICATIONS

- Antenna feedthroughs for aircraft

- Hermetic sealing for rigid, flexible and hybrid bomb fuse circuit boards

- High-pressure fiber optic PotCon® feedthrough for hydraulic fluid level measurement

- Hermetic seal technology of cable harnesses keep moisture out of missile and munition control systems

- Military actuators for land, sea, and air systems

- Hermetically sealed laser, LiDAR and Sonar systems using feedthroughs and circuit seals

- Sensor interconnects including hermetic transmission applications

- Back-potted MIL-spec connectors for power, signal, and fiber cables

- Power and signal leads for military fuel pump applications

- Oil debris detection systems on aircraft monitoring devices

- Upgrade penetrations in sealed military systems from IP-68 to hermetic levels

- Complex, ruggedized harness assembly with hermetic connectors

FAQ

What are MIL-Spec Electrical Connectors?

MIL-Spec Electrical Connectors are military-standard connectors designed for use in military and aerospace applications. These connectors adhere to strict standards defined by the U.S. Department of Defense to ensure reliability, durability, and performance in challenging environments.

What makes Aerospace Electrical Connectors unique?

Aerospace Electrical Connectors are specialized connectors designed for use in the aerospace industry. They offer high performance, reliability, and durability to withstand the harsh conditions of aircraft, spacecraft, and other aerospace systems. These conditions include temperature, pressure, shock, and vibration requirements from standards such as MIL-STD-810.

Can MIL-Spec Bulkhead Connectors be customized for specific applications?

Yes, MIL-Spec Bulkhead Connectors can be customized to meet specific application requirements. Douglas Electrical specializes in converting non-hermetic connectors into hermetic ones, creating lightweight, plug-and-play assemblies tailored to customer needs. MIL-spec bulkhead connectors can include various mechanical interface choices from standard flange mounts, threaded connections, face seals, and even custom flange integration.

How do Military Hermetic Connectors differ from standard connectors?

Military Hermetic Connectors provide a hermetic seal, offering enhanced protection against harsh environmental conditions under pressure and/or vacuum. They are specifically engineered for applications where maintaining a sealed environment is crucial for component integrity.

Can Douglas Electrical provide hermetic solutions for high-density electrical connections in military applications?

Yes, Douglas Electrical specializes in designing and manufacturing hermetic solutions, including high-density electrical connections, for military applications. Our expertise covers a range of connectors and assemblies tailored to the unique demands of military and aerospace systems.

Are Douglas Electrical connectors compliant with international regulations for military applications?

Yes, Douglas Electrical connectors are designed and manufactured in the US and can be configured using Commercial Off-the-Shelf (COTS) components. Additionally, we support International Traffic in Arms Regulations (ITAR) regulated assemblies through design, tooling, certification, and testing.

Product Image Examples

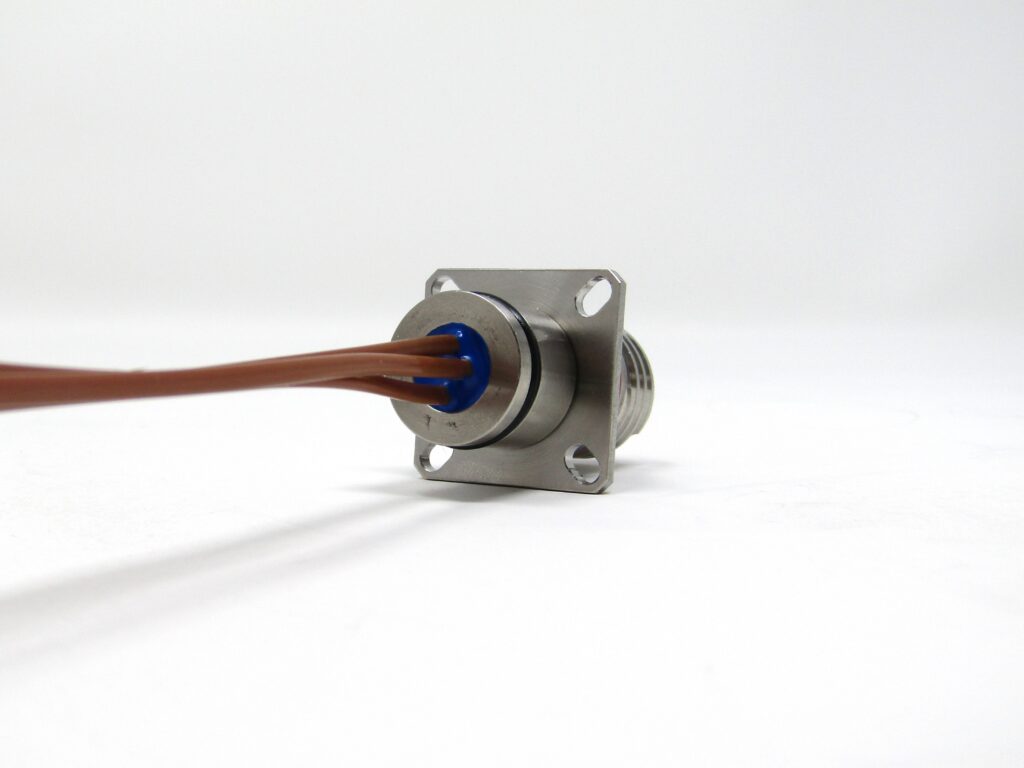

Customized flange electrical feedthrough assembly

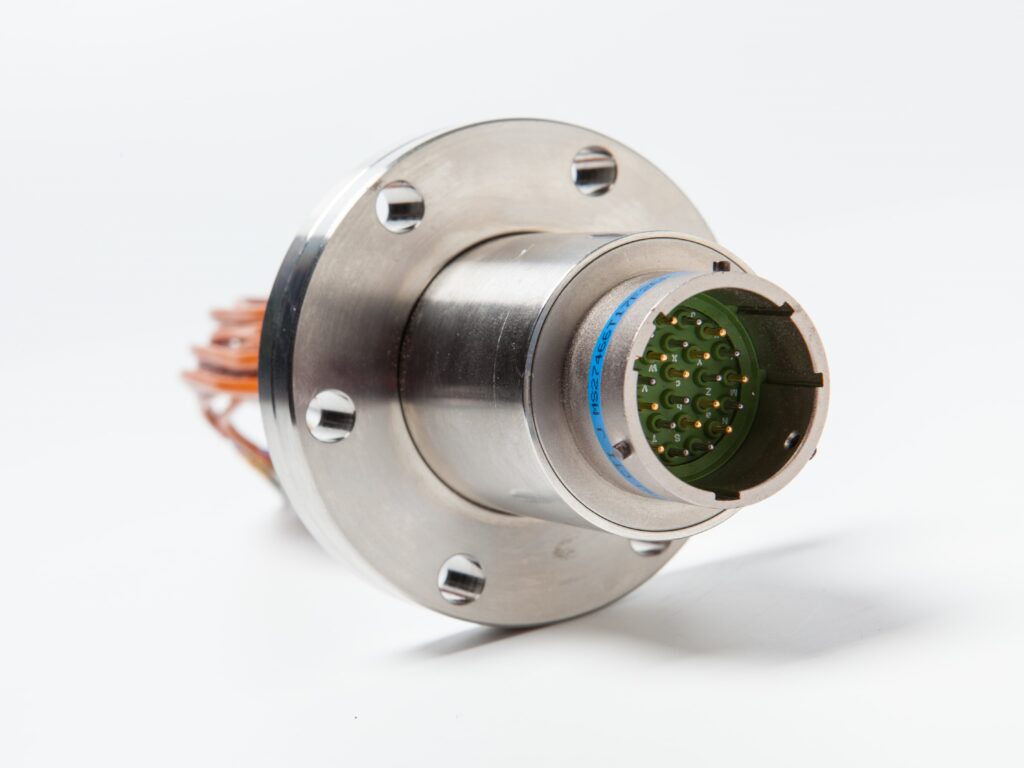

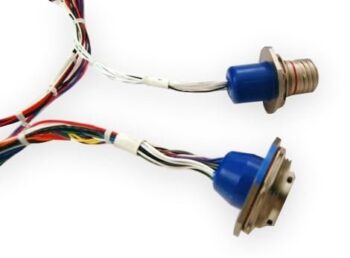

Hermetic military assembly with integral cable harness and customized housing

Custom LED hermetic wire harness assembly

DFM assembly simplifies installation while improving reliability.

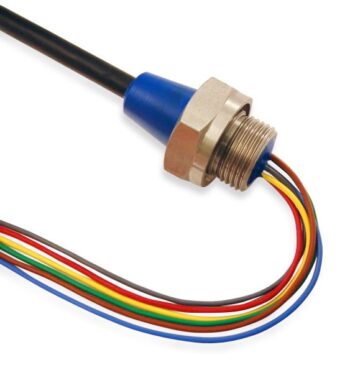

Electrical Feedthrough Harness

Customized electrical feedthrough with integral housing, wire, and electrical connection.

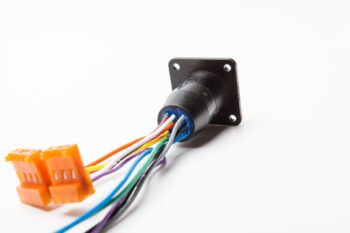

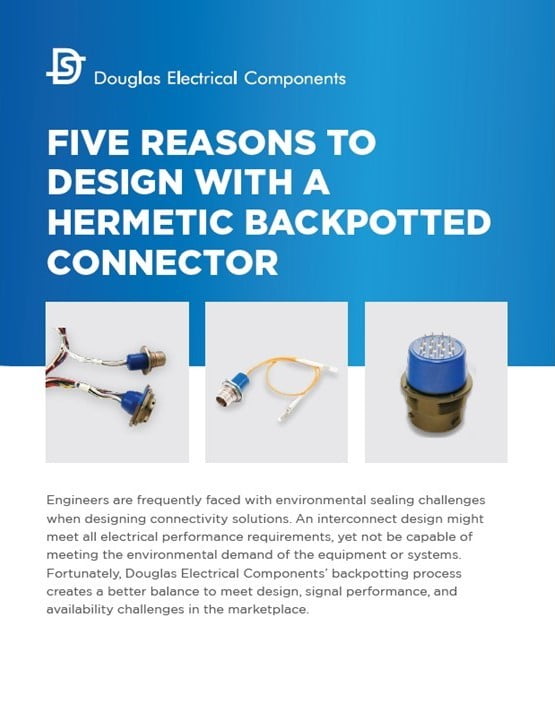

Integral Harness Backpotting Solutions

Create hermetic connector assemblies directly within your wire or cable harness assemblies

Custom Hermetic Plate Assembly

Plate assemblies available for various Military and Aerospace applications.

Hermetic 38999 Assembly Side View

Create a customized hermetic seal for pressure applications

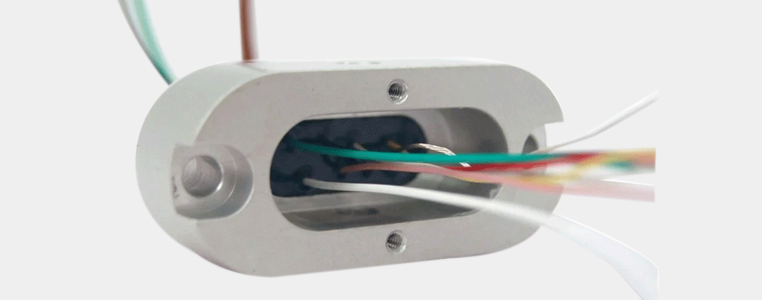

Sensor Hermetic Assembly

Hermetically sealed electrical feedthrough from PCB to cable in threaded housing

Custom Molded Hermetic Connectors

Create customized hermetic connector assemblies with plastic connectors and integral wires or cables

Sealed MIL-spec Connector Harness

Customer-specific design with moisture-tight sealed connector ends

Custom complex cable harness

Custom complex cable harness

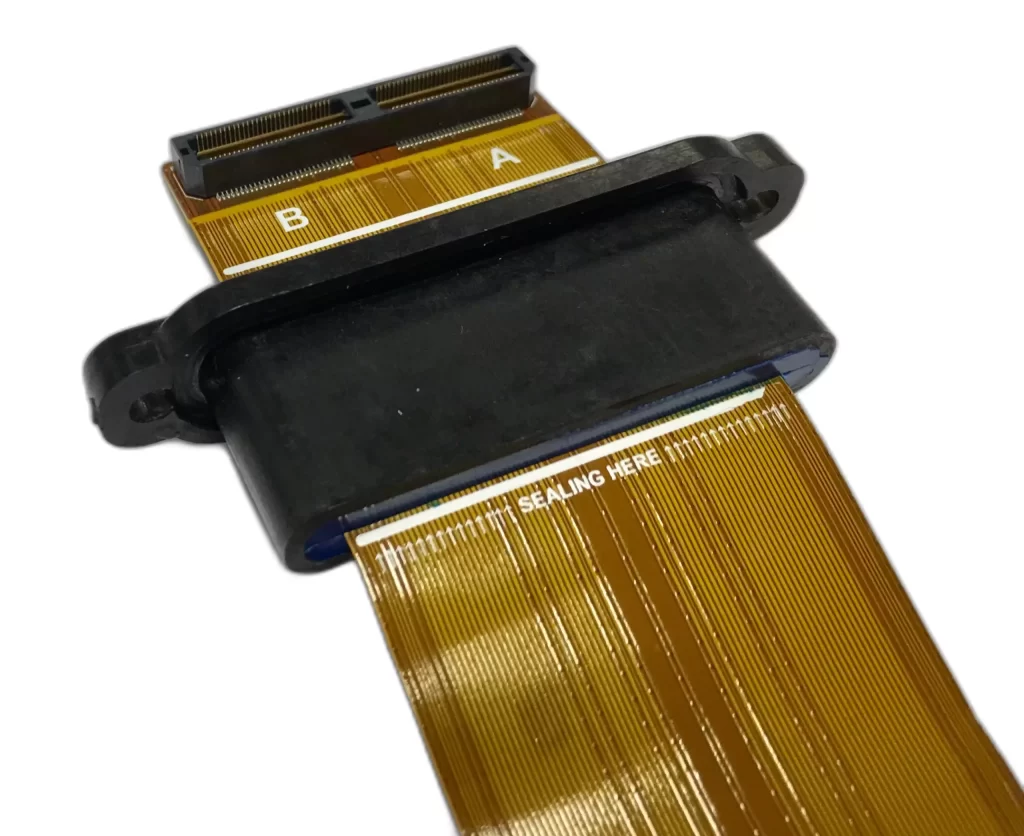

Hermetic flex circuit assembly

Hermetic flex circuit integrated with circular connector rendering

Hermetic USB 38999 Mil-Spec Backpotted Connector

Backpotted USB connector with MIL-DTL-38999 shell with mating USB connector and epoxy extension

Backpotted MIL-spec connector with integral PCB Pins

Backpotted MIL-spec connector with integral PCB Pins

Fiber Optic 38999 Connector

Integral optic fiber wire assembly with backpotted 38999 connector for plug-and-play use

Hermetic RBTW optical fiber connectorized feedthru

OptiSeal RBTW MIL-spec connector-to-wire feedthrough creates a hermetic package with customer-specific wire

Hermetic wire-to-cable feedthrough

Create hermetic electrical feedthroughs between wire and cable. This design features a simple O-ring flange.

PBTW Custom Flange connector to wire feedthru

MIL-spec hermetic connector with custom rectangular flange and integral wires

Hermetic Control Box Assembly

Hermetically sealed housing from circuit board to wire assembly. This assembly creates a plug-and-play electrical connection that is hermetically sealed and saves installation time. This is a common configuration in IoT devices.

Hermetic MIL-spec Connector

Example of a non-hermetic connector using epoxy backpotting to create a hermetic seal

Electrical MS Connector Hermetically Backpotted

Electrical MS Connector Hermetically Backpotted

Hermetically Sealed Sensor Assembly

Hermetically sealed sensor assembly where the sensing element is exposed to the operating environment, but the housing and wire are hermetically sealed.

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

Fiber Optic Feedthrough with Epoxy Strain Relief Extension

High Density Fiber Feedthru

Hermetic fiber optic cable seals designed into a high-density flange assembly. This design combines multimode and single-mode fibers in a CF flange.

Fiber Optic Cable Feedthru

OptiSeal Fiber Optic feedthroughs can be provided in cable or connector-based styles.

Documents

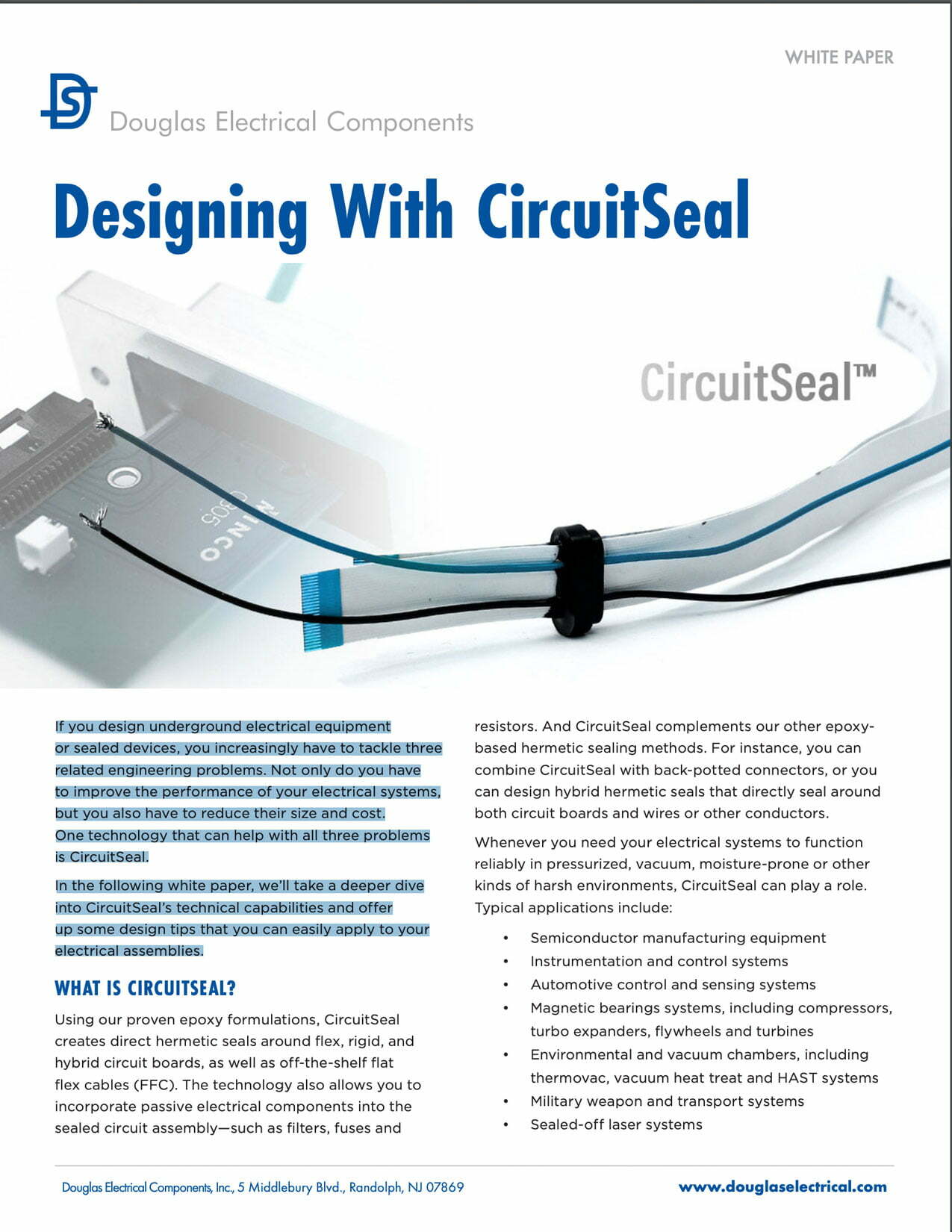

Documents & Downloads

Whitepapers

Certificates & Standards

Related Products

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Backpotted Connector Assembly

All the benefits of a hermetic connector with a custom mechanical interface.

Hermetic Backpotted Connector

Industry-leading made-to-order hermetic bulkhead connector assemblies

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

38999 Hermetic Connectors

Made-to-order hermetic MIL-DTL 38999 connectors and

assemblies available in less time than a "standard" 38999 hermetic connector.

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Cable Harnesses

Wire and cable harnesses designed and manufactured to your specific requirements.

Liquid Tight Wire / Cable Feedthrough Seals

Create a high-density, sealed wire or cable electrical feedthrough

for use in hazardous and/or non-hazardous areas.

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

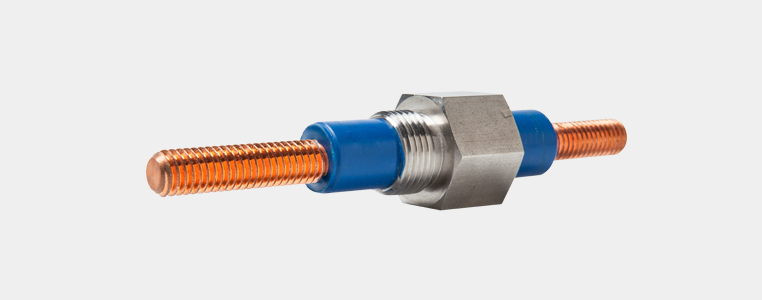

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of

up to 1,000 amps and 15kV.