Glovebox Feedthroughs

Hermetic feedthroughs, connectors, and assemblies to connect

to your glovebox instrumentation and controls.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

A glovebox is an enclosure designed to protect the operator and the environment from hazardous materials or processes. It typically consists of a transparent, airtight chamber that is equipped with gloves or other manipulators, which allow the operator to interact with the materials or processes within the chamber without coming into direct contact with them.

Douglas Electrical Components provides reliable epoxy-based glovebox hermetic feedthroughs for nuclear, medical and laboratory gloveboxes – bringing power, signal and data into critical environments while protecting operators from hazardous conditions or substances. Our sealing technologies are hermetically, electrically, and optically tested for long-term performance in applications involving inert atmosphere containment and hazardous material handling, including Plutonium (Pu). Our glovebox feedthroughs are engineered and manufactured in the United States.

Custom Feedthrough Designs for Gloveboxes

We’ll partner with you to design a hermetic feedthrough into an existing glovebox setup or a newly fabricated one for electrical penetration. We offer standard face seals, flanges, and NPT threads as an interface to ensure the right seal for the application. We also can combine multiple electrical connection types into a single feedthrough plate. Augment wire and cable feedthroughs with integral connectors, which simplifies installation within the glovebox while maintaining a hermetic barrier for Plutonium (Pu), radioactive, and other hazardous materials. We offer design capabilities for multiple glovebox environments including radiation, cryogenics, and explosive atmospheres.

Decades of Experience with National Laboratories

We have successfully designed and developed glove box electrical feedthroughs for American and Canadian government labs including: Los Alamos National Laboratory (LANL), Lawrence Livermore National Laboratory (LLNL), Pacific Northwest National Laboratory (PNNL), Savannah River National Laboratory (SRNL), Oak Ridge, Ames, Canadian Nuclear Laboratories (CNL), Idaho National Laboratory (INL), SLAC National Accelerator Laboratory (SLAC), Brookhaven National Laboratory (BNL), Atomic Energy of Canada Limited (AECL), and Fermi National Accelerator Laboratory (Fermilab) / Argonne National Laboratory (ANL).

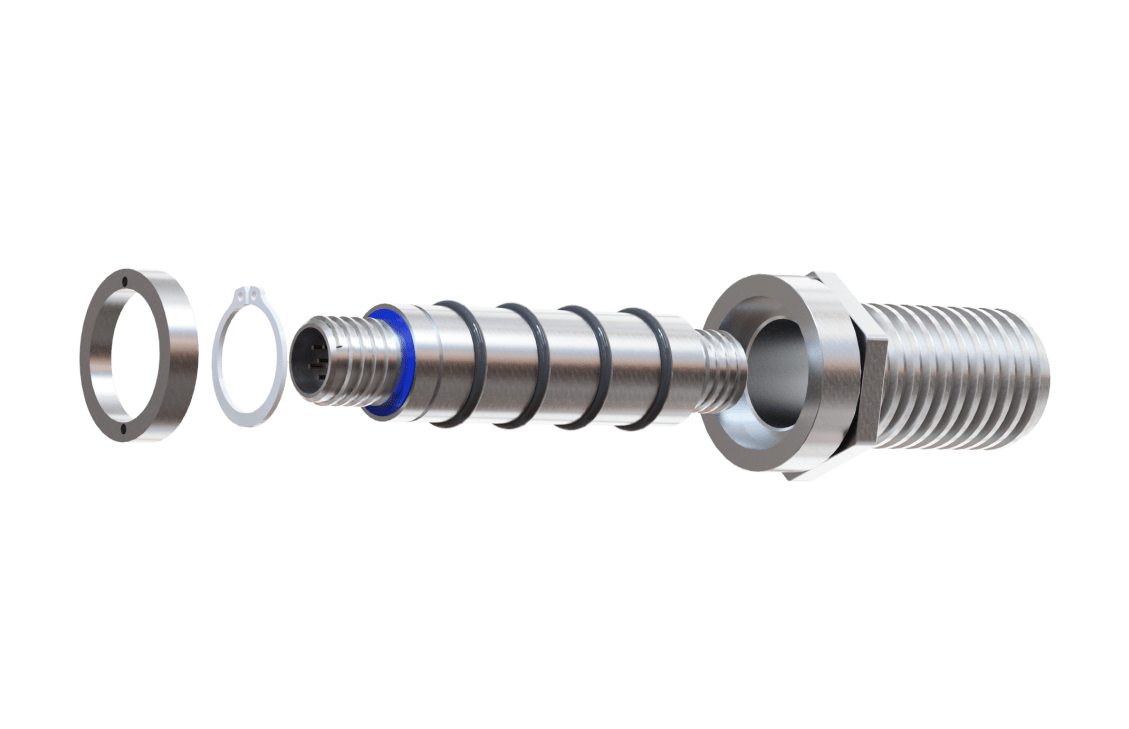

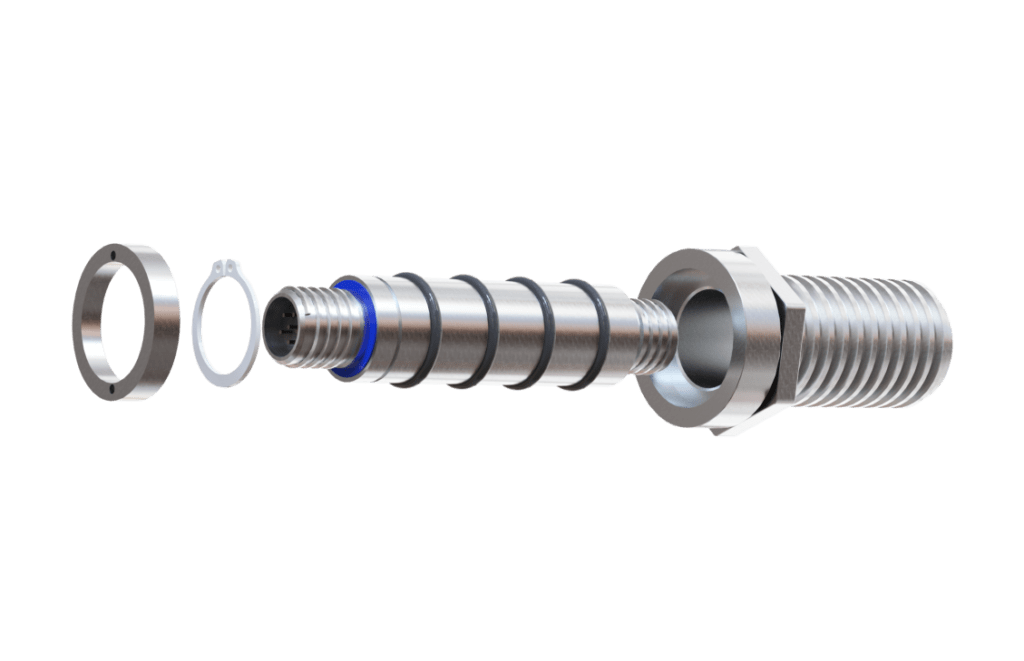

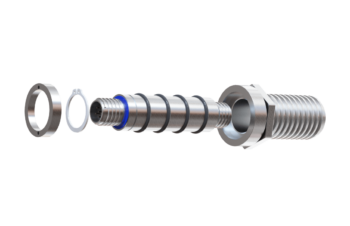

Push-through Feedthrough Assembly Capabilities

Key Benefits

- Hermetic insert housing can be replaced during maintenance and upgrades without breaking the hermetic seal, preventing contamination of the outside environment.

- Glove box feedthrough assembly is designed for quick and easy installation, reducing labor costs and downtimes.

- Feedthrough conductor options include connectors, wires, cables, and fibers

- Bulkhead housing options include O-ring face seals, weld-in, NPT, bolt on flange and custom designs to fit your specific requirements

Connection Options Include:

- Circular connectors including MIL-spec, metric, and NEMA power

- USB, RJ-45/CAT6, and Coaxial

- Fiber Optic

- High Voltage

Features

TECHNICAL ADVANTAGES

- Epoxy seals can withstand hot nuclear environments.

- Push-through feedthrough designs enable the hermetic insert housing to be replaced during maintenance and upgrades without breaking the hermetic seal and thus

contaminating the outside environment. - 100% electrically and hermetically tested for long-term performance.

- Customization to create high-density feedthroughs with the electrical connections and mechanical interfaces that are needed to complete testing.

- Traceability and MIL certificates are available upon request.

EXAMPLE APPLICATIONS

- Push through assemblies

- UHV feedthrough assemblies such with standard mechanical interfaces

- Convenience packages for power such as 220V assemblies

- Standard packages for D-sub, Micro-D, and banana plug connections

- USB / RJ45 commercial hermetic connectors feedthroughs

- Customized hermetic cable assemblies for microscopes, cameras, and instrumentation

- Push/pull connectors for simpler use with gloves

- MIL/Industrial connectors such as M12 for instrumentation

- Cooling fluid transfer lines available for integration

- Detonation equipment requiring high voltage, fiber optic, and circuit seals in positive pressure environments

CERTIFICATIONS

- ITAR-DDTC

- DFARS

- NIST

- ISO-9001:2015

- ISO-14001:2015

- Traceability and military certifications available

- Harnessing performed by IPC 620 certified operators

ORDERING & DELIVERY

- Engineered and manufactured in the USA

- Ongoing technical support

- Made to order in 4 to 6 weeks

- Expedited options available

FAQ

What is a glovebox?

There are two types of gloveboxes that are mostly unrelated. The glovebox in your vehicle is a convenient location on the passenger side of your vehicle to fit a pair of gloves for those cold morning commutes.

A glovebox enclosure is utilized in the test and measurement space as an enclosure for testing and isolation. Unlike a vacuum chamber which eliminates atmosphere, the glovebox enclosure, especially those equipped with glove box electrical feedthroughs is hermetically sealed to isolate the user from the pressurized environment. Gloves are designed and mechanically installed to let the operator move items within the enclosure as needed while not exposing the user to the environment.

What are some uses for gloveboxes?

Gloveboxes are designed and manufactured for various uses. From pharmaceutical and laboratory testing to industrial and radiation environments, gloveboxes have a host of uses. Generally, instrumentation and controls are installed within the glovebox. Feedthroughs, crucial for industrial glove boxes, provide the ability to transmit power for the equipment or the signal. This can include optical fibers for more advanced systems. Microscopes, cameras, and sensors are some of the most popular types of instruments used with glovebox assemblies.

What is a glovebox feedthrough?

Feedthroughs for gloveboxes are an essential aspect of glovebox design, as they are specifically engineered to transmit power or signals into or out of the enclosure. They require a hermetic seal to ensure that there is no leakage past the feedthrough, keeping the inside environment as intended and the operator’s environment also free from hazards. Glovebox feedthroughs can encounter some chemical and radiation exposure, depending on the type of testing being conducted. Douglas Electrical Components manufactures hermetically sealed glove box electrical feedthroughs that are compatible with various liquids and gases.

Do feedthroughs utilize robotics?

Yes, in harsh environments, a robot can be an expensive, yet safer alternative. This can include environments with radiation as well as detonation testing. Robotics require feedthroughs to feed the power to operate and signal to control. Douglas partners with glovebox manufacturers as well as owners and operators to design and manufacture the best solution for the tests being conducted.

What is the purpose of a positive pressure glove box?

A positive pressure glove box, like a sealed glove box, ensures that the internal pressure remains higher than the surroundings. This prevents contaminants from entering, making it ideal for applications where a clean and controlled environment is essential, like in semiconductor manufacturing.

How do I choose the glovebox hermetic feedthrough for an application?

Choosing the right glovebox electrical feedthrough requires a careful consideration of several factors, including the type of conductor needed, specific installation requirements, environmental conditions inside the glovebox, etc. Our team will assist you in choosing the right glovebox feedthrough for your needs.

Featured Products

Glovebox Solutions

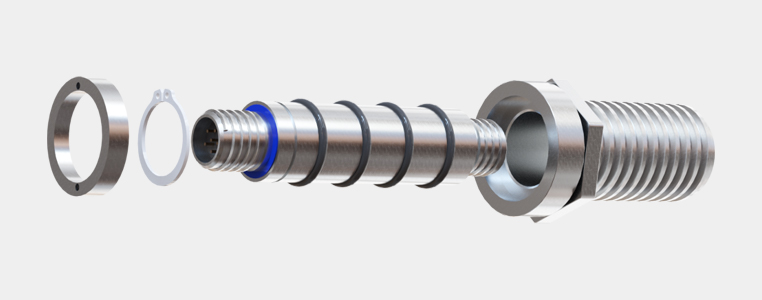

Hermetic Push-through Assembly

Glovebox hermetic push-through feedthrough to allow replacement while maintaining hermetic seal

hermetic push-through feedthrough assembly for glovebox applications

hermetic push-through feedthrough assembly for glovebox applications

PTR Tooling

Tooling installed on PTR vacuum face seal housing to replace the existing connector insert with blank or new feedthrough

PTR Hermetic Push-through Feedthrough

Hermetic push-through feedthrough design with vacuum face seal and D38999 connectors

PTR Push-through Inserts

PTR series hermetic push-through inserts featuring MIL-spec connectors and four O-ring seal

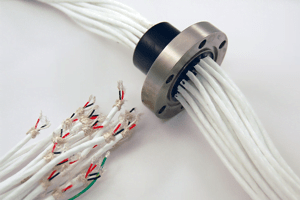

Glovebox Convenience Cable Feedthrough

Glovebox Convenience Cable Feedthrough creates a wired connection to power equipment in Glove boxes and test setups. The cable allows for flexibility to reach the equipment in the glovebox without added extension cords or compromising space.

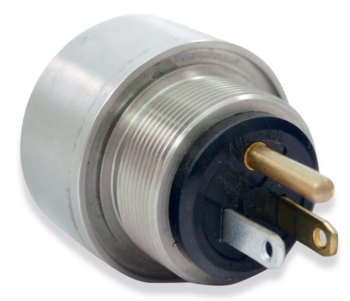

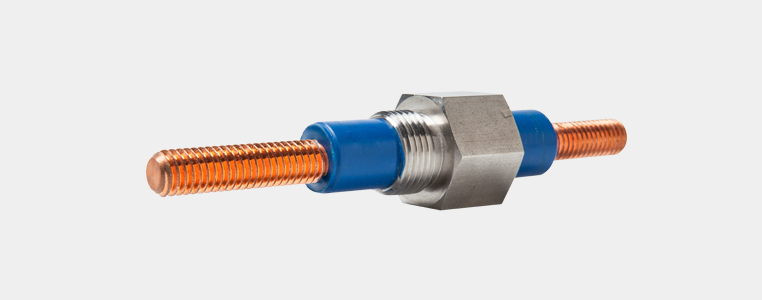

Hermetic Convenience Feedthrough

Power feedthrough for glovebox applications

Hermetic Convenience Feedthru

Hermetic bulkhead convenience feedthrough to provide power to instrumentation within gloveboxes and chambers is designed with a vacuum face seal for simplified installation.

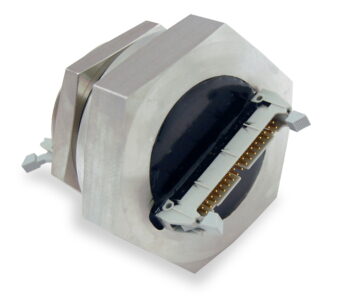

CF feedthrough with RJ45 and d-sub connector

CF feedthrough with RJ45 and d-sub connector; combine various connection types with minimal to no tooling.

Compact Hermetic USB Assembly

USB-C hermetic bulkhead connector with small jamnut design

USB Wire and Connector Feedthroughs

Hermetically seal USB connections with wire or connector interfaces for vacuum and pressure applications

USB-C PotCon Hermetic Connector

USB-C hermetic connector in compact flange clamp mount design

15 position Hermetic Micro-D reversible hermetic feedthrough angled pin view

15 position Hermetic Micro-D reversible hermetic feedthrough angled pin view

hermetic bulkhead hdmi-feedthrough side

Hermetic bulkhead HDMI-feedthrough is designed with a face seal to simplify installation and transmit signal in vacuum or positive pressure.

Hermetic Coaxial Feedthrough with QF50 Flange

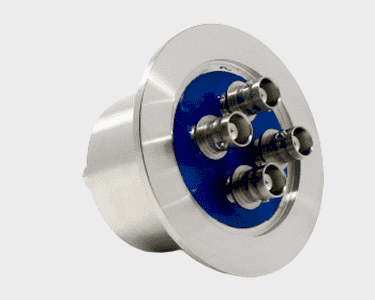

Hermetic coaxial feedthrough with QF50 flange and four BNC connections

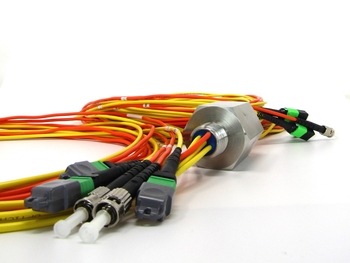

Fiber Optic Cable Feedthru

OptiSeal Fiber Optic feedthroughs can be provided in cable or connector-based styles.

PotCon MTP Fiber Optic Connector Feedthrough

PotCon MTP Fiber Optic Connector Feedthrough

PotCon hermetic plastic bulkhead connector

PotCon hermetic plastic bulkhead connector. Douglas can hermetically seal virtually any connector material into a bulkhead feedthrough.

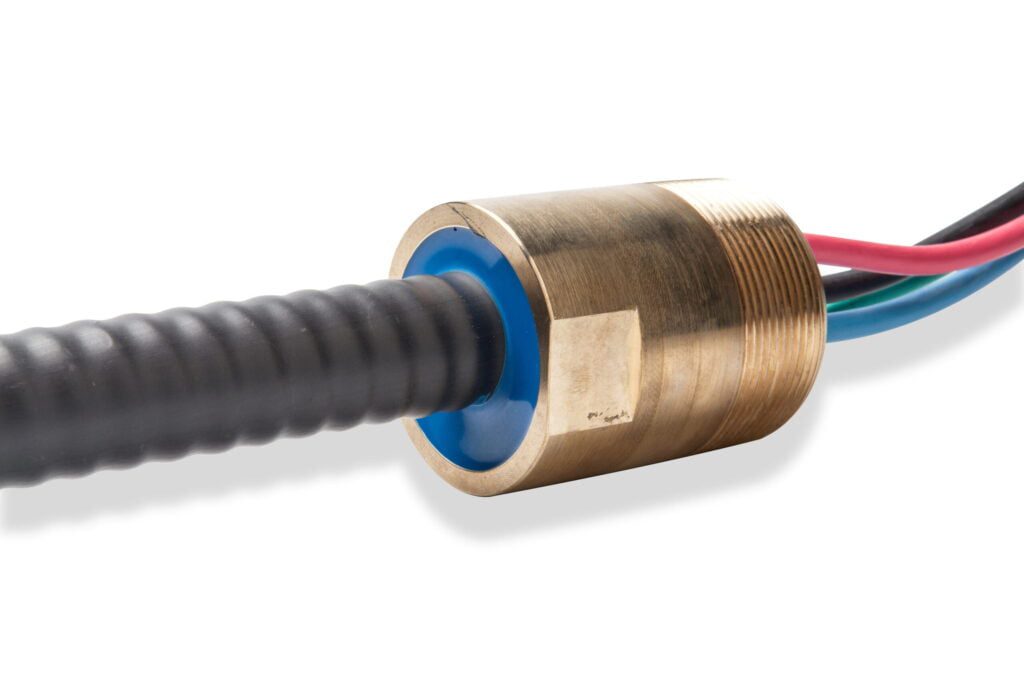

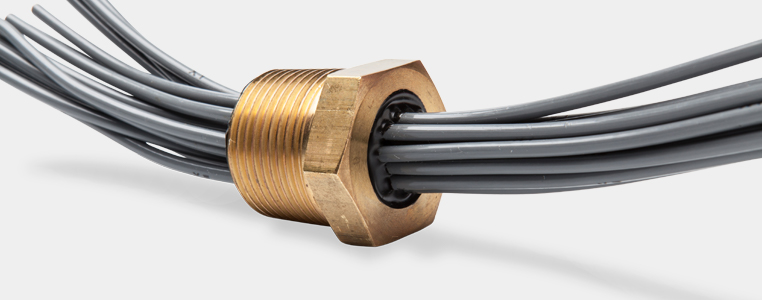

Explosion-proof Wire Bushing - Cable to Wire

Explosion-proof wire bushing seal; combine wires, cables, and connectors on either end of the bulkhead feedthrough fitting.

PotCon SMA hermetic feedthrough connector

PotCon SMA hermetic feedthrough connector with UNF thread. Select single connection feedthroughs or integrate into a larger plate assembly.

20kV 15nA DuctorSeal Hermetic Wire Feedthru

High Voltage 20kV 15nA DuctorSeal hermetic wire feedthrough

PotCon ribbon cable hermetic assembly

PotCon ribbon cable hermetic assembly. If the connector is commercially available, we can source it and integrate it within an electrical feedthrough.

Multi-Fiber Type Feedthrough

Hermetic fiber optic NPT feedthrough with SM and MM fiber in the same mechanical interface.

Hermetic 6 position M8 plug to receptacle feedthrough with 3/4" NPT threaded connection

Hermetic 6 position M8 plug to receptacle feedthrough with 3/4" NPT threaded connection

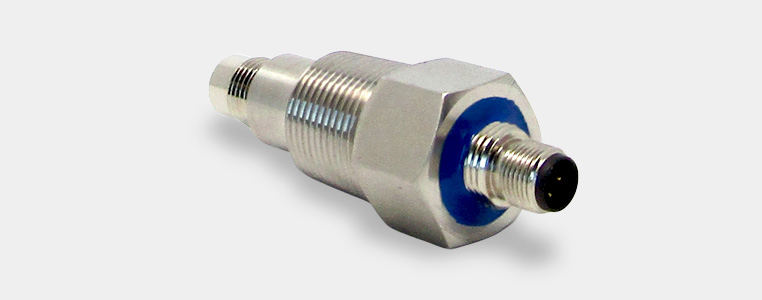

Hermetic M12 NPT Feedthrough

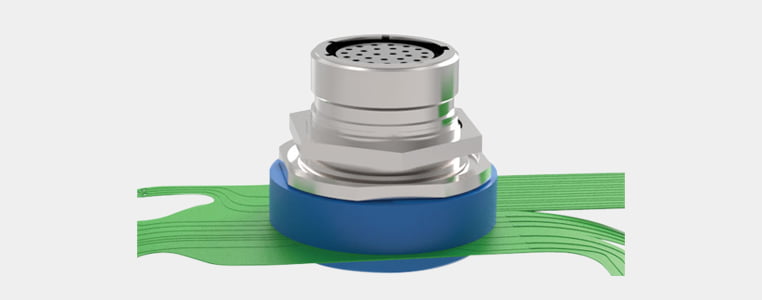

Hermetically sealed M12 bulkhead feedthru with 3/4" NPT

Hermetic M23 Feedthrough

Hermetically sealed M23 bulkhead feedthrough connector for glovebox mounting

Hermetic M23 Bulkhead Feedthrough

front view of hermetic NPT feedthrough with M23 electrical connections

PTR Series Tooling - Front

hermetic push-through tooling for replacement of hermetic inserts

Hermetic M12 Feedthrough with NPT Bulkhead Mounting

Connectorized 6 Position M12 hermetic cable assembly designed for NPT bulkhead mounting

Documents

Documents & Downloads

Material Data

Certificates & Standards

Related Products

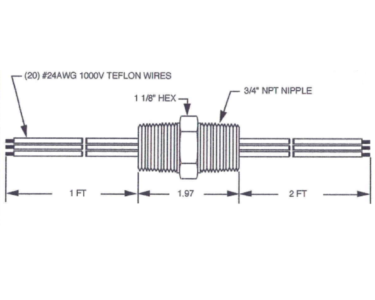

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

Push-through Feedthroughs

Change electrical connections without breaking hermetic seals

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Fiber Optic Feedthroughs

Customized optical fiber feedthroughs & connectors are available as pre-tested assemblies.

Hermetic Terminal Seals

Hermetic terminal seals handle operational loads of

up to 1,000 amps and 15kV.

Custom Hermetic Flange & Plate Assemblies

Multi-port hermetic assemblies accommodate any feedthrough configuration,

with time and troubleshooting minimized.

Coaxial Feedthroughs

Hermetically seal coaxial connections for vacuum and pressure applications.

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

D-sub Connectors

Plug-and-play hermetic D-sub connector with reversible mounting.

Micro-D Connectors

Hermetic Micro-D connectors with fully reversible mounting for vacuum applications.