Automotive Feedthroughs

Hermetic sealing capabilities for fuel pumps, batteries, sensors, wires, circuits, and more.

Applications

-

Aerospace & Defense

-

Air Conditioning & Refrigeration

-

Alternative Energy

-

Automotive Feedthroughs

-

Immersion Cooling Hermetic Feedthroughs

-

Cryogenic Feedthroughs

-

Electrical Power Transmission & Distribution

-

Liquid/Oil Immersed Transformer Feedthroughs

-

Glovebox Feedthroughs

-

Hazardous Locations / Oil & Gas

-

Instrumentation & Controls

-

Magnetic Bearings

-

Healthcare and Medical Equipment

-

Semiconductor Equipment

-

Space Simulation

-

Vacuum Electrical Feedthroughs

Locate a Technical Sales Engineer

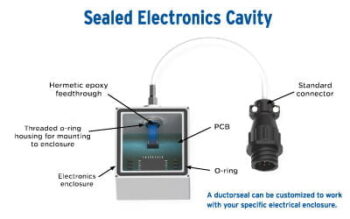

Douglas Electrical Components designs and manufactures a variety of hermetic electrical feedthroughs and connectors for the automotive industry. As vehicles are getting smarter and more connected, our business is designed to support customers from R&D to large scale production. Our sealing technology provides a robust, chemically compatible, hermetic seal between various parts of the vehicle. For example, in LiDAR applications, our electrical feedthroughs hermetically seal the camera to prevent water from penetrating the housing of the sensor and fogging the lens or creating a short. Our products are used to hermetically seal an electrical connection with automotive fuel pumps to ensure a long-lasting connection. Additionally, we can provide the service of sealing standard automotive and off-road connector designs that cannot meet the existing environmental constraints such as water, dust, and fretting from vibration.

Reduce complexity and weight while hermetically sealing your housing, connector, or feedthrough.

Our automotive electrical feedthroughs are hermetically sealed in different ways. Douglas Electrical Components can direct cast our epoxy into a customer-designed housing; this can create a low-profile, lightweight assembly that is hermetically sealed to the exact form a customer requires.

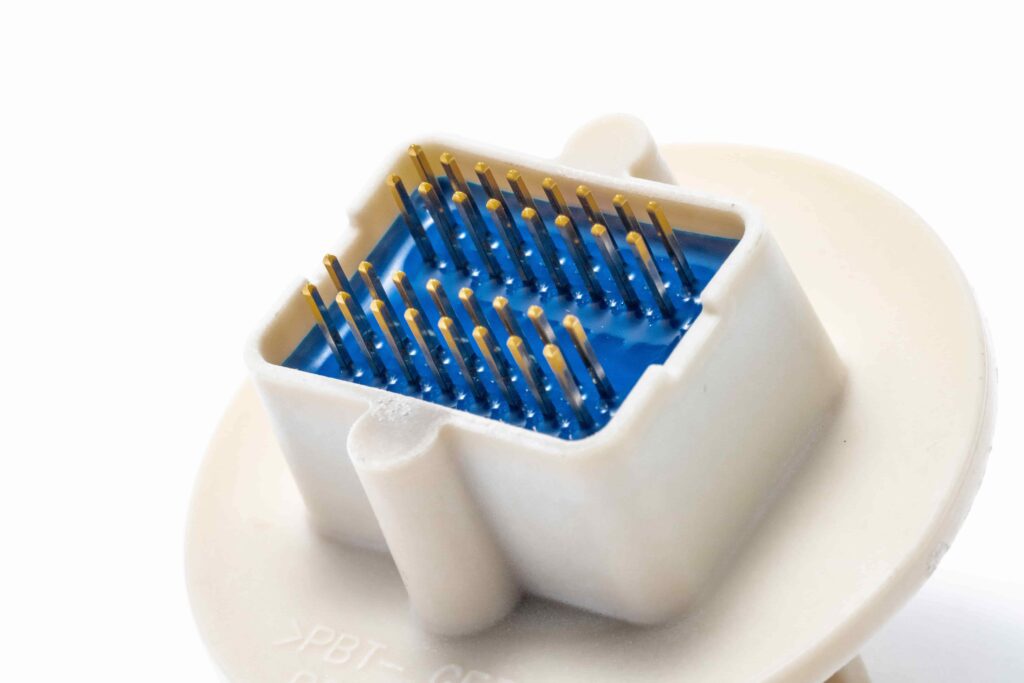

Douglas Electrical components offers backpotting connector designs. This process allows us to either hermetically seal non-hermetic connector designs with a variety of integral electrical connection options including pins, sockets, wires, cables, and optical fibers. This service is scalable from Test & Measurement applications in the automotive industry to large scale production. Our hermetic epoxy is not limited to internal combustion engines. Our automotive hermetic connector solutions also span alternative fuels such as hydrogen and hybrid and electric vehicles and charging systems.

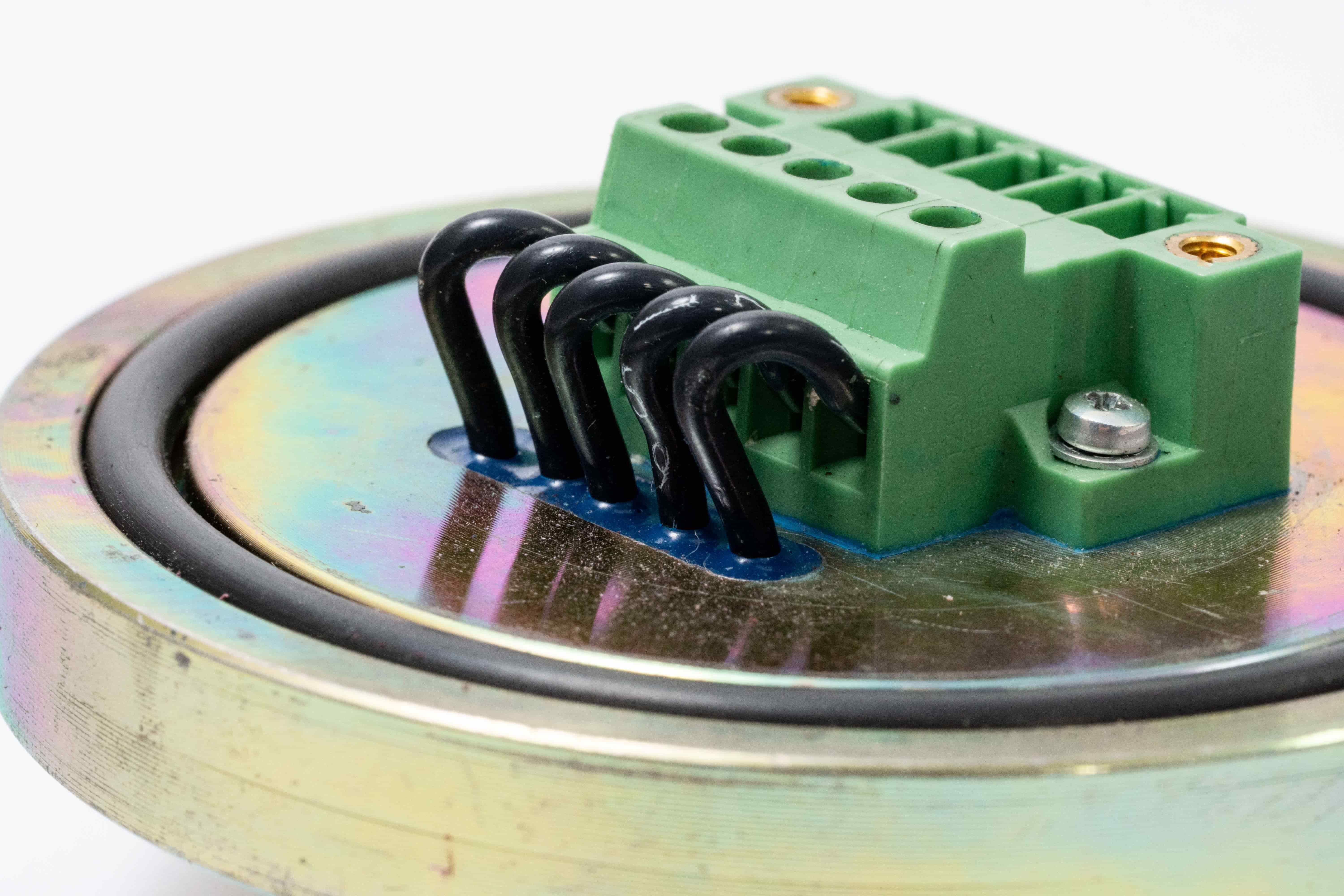

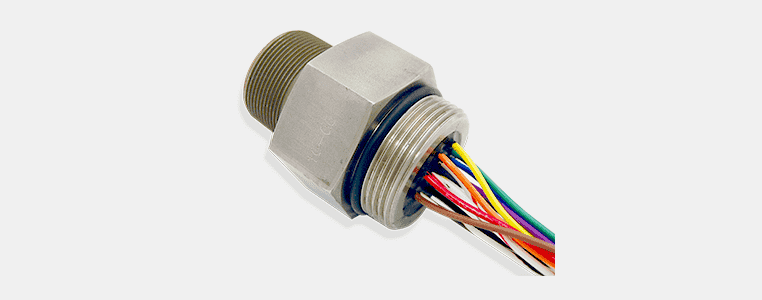

Radial O-ring feedthroughs are also popular within automotive platforms. This seal type is suitable for both vacuum and high pressure, features simple installation, and can integrate redundant sealing. Customized metal feedthroughs and threads are also available for customers.

Featured Application | Battery Immersion Cooling

Douglas Electrical Components manufactures hermetic feedthroughs for both automotive battery thermal management and immersion cooling applications. Using a chemically inert, hermetic epoxy, Douglas can feed or pass through wires of virtually any type into a dielectric fluid environment. Douglas will not only seal to the wire jacket, but directly to the conductor passing in and out of the liquid environment. With the seal being hermetic, it is protected beyond IP ratings and 100% tested via helium mass spectrometer to ensure no leakage to allow access to the battery immersion cooling housing.

Key Features

- Hermetically sealed beyond industry standard IP ratings

- Complete mechanical and electrical design flexibility

- Minimize components with a simplified hermetic design

- Chemically inert epoxy seal features compatibility with oils and dielectric fluids

Automotive Solutions

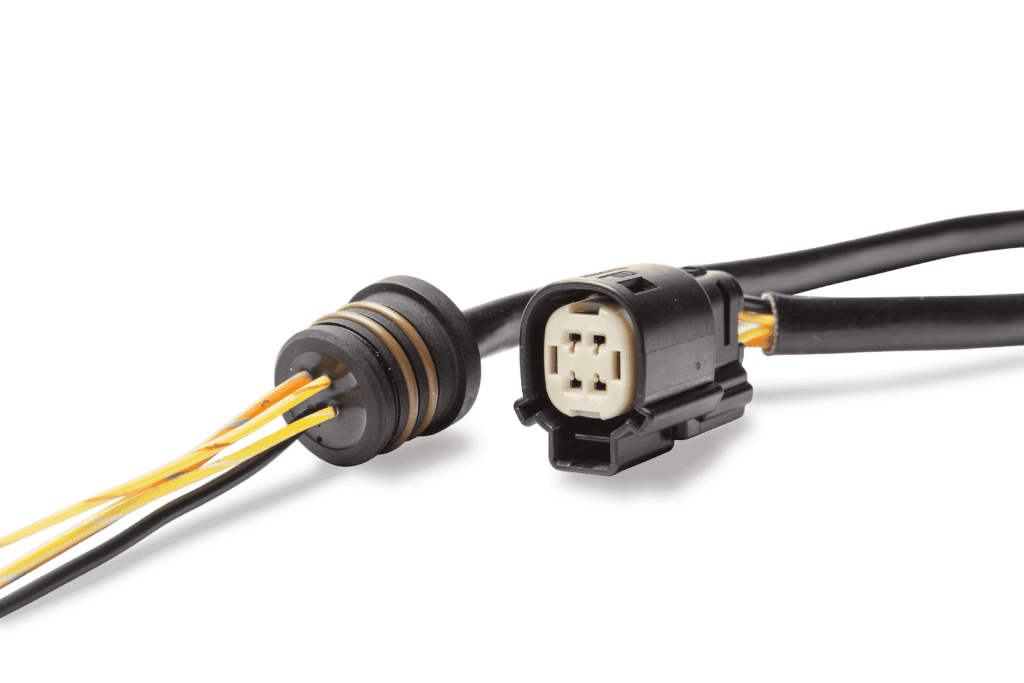

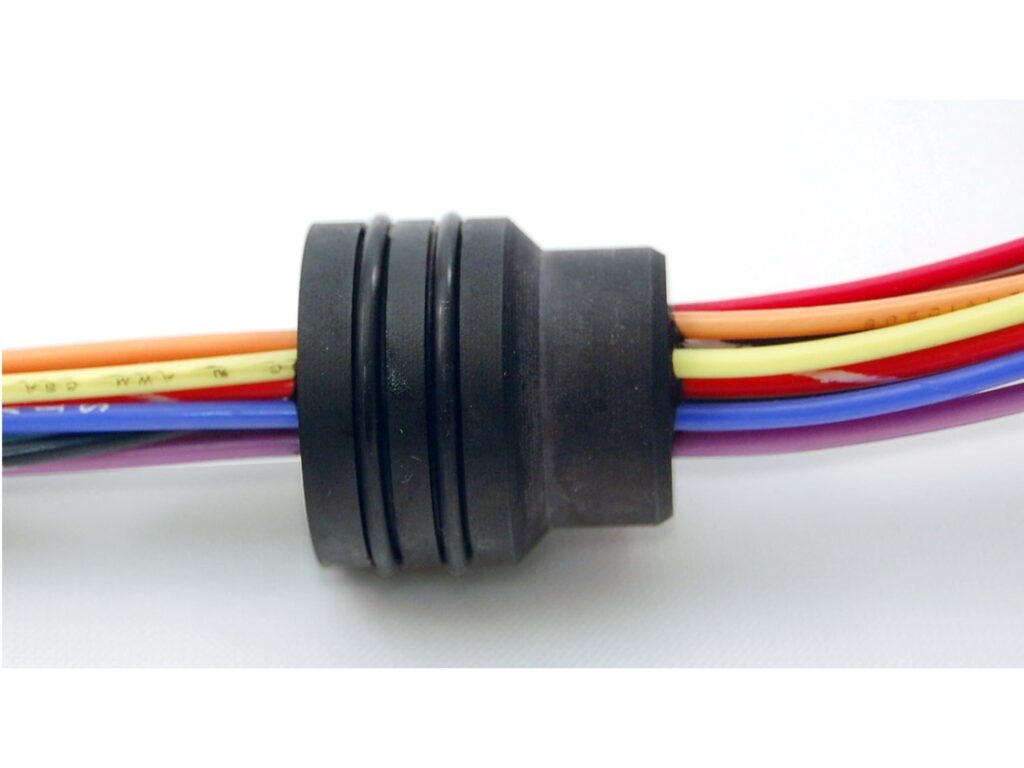

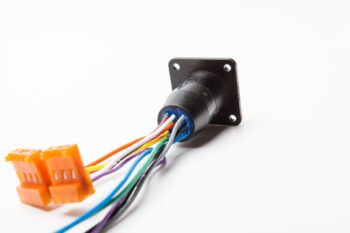

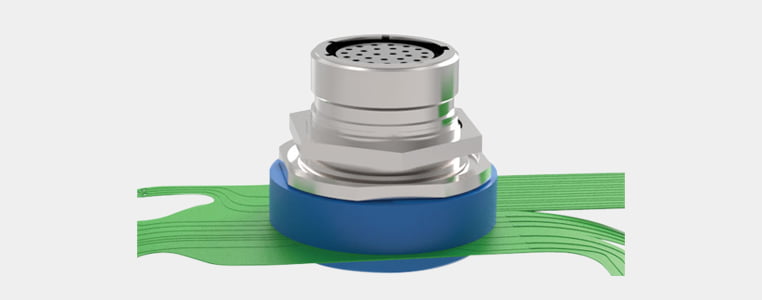

Radial O-ring hermetic wire feedthrough

Radial O-ring hermetic wire feedthrough. Integrate plastic or metal housings and save installation time with an O-ring seal rated for high pressures.

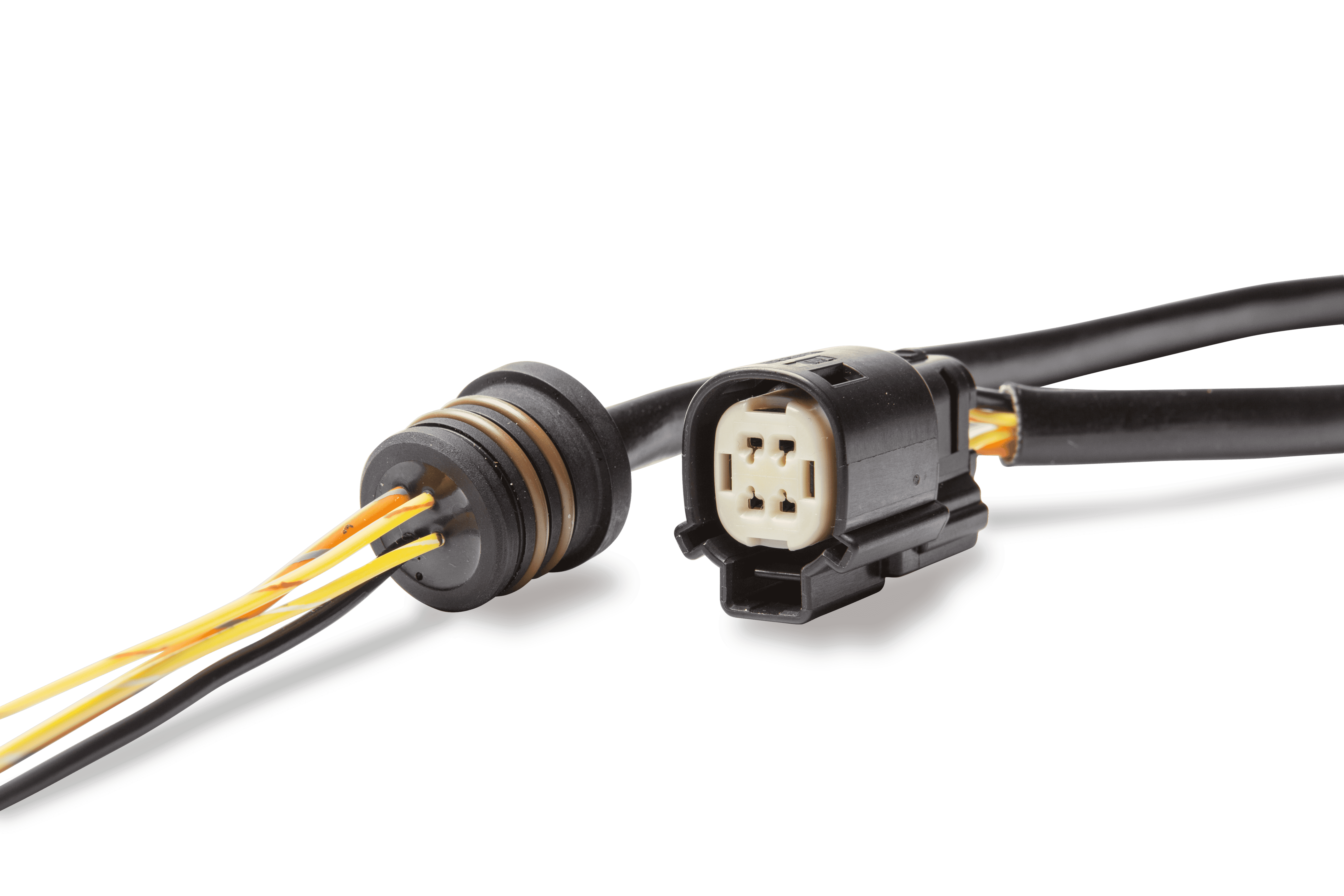

Custom Molded Hermetic Connectors

Create customized hermetic connector assemblies with plastic connectors and integral wires or cables

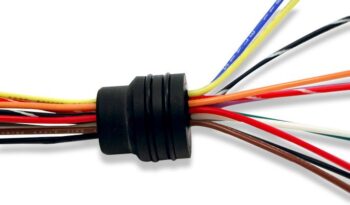

Sealed Fuel Pump Wires

Hermetically sealed wires in fuel pump assembly

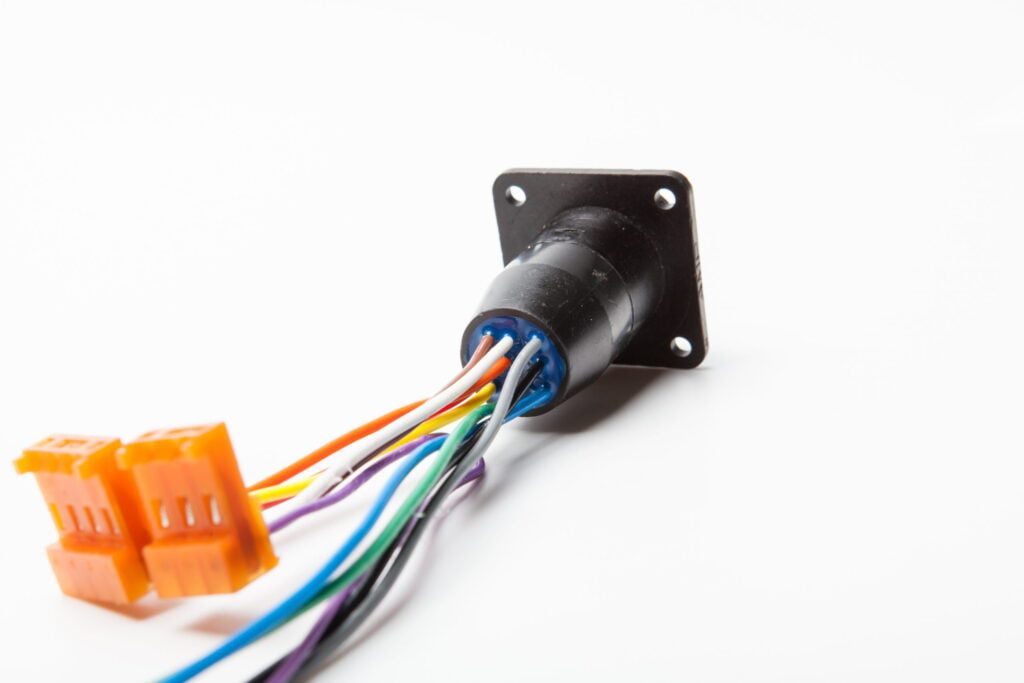

Hermetic Cable Assembly

Automotive hermetic assembly with integral cables, radial O-ring seal, and connectors

Electrical Feedthrough Harness

Customized electrical feedthrough with integral housing, wire, and electrical connection.

Hermetically sealed MIL-spec connector with integral pins

MIL-spec backpotted connectors for military, aerospace, industrial, and autosport applications.

Dual O-ring Wire Feedthru

Automotive hermetic feedthrough with double O-ring seal

Hermetic SAE Wire Feedthrough

Hermetically sealed wire assembly through SAE housing with integral connectors

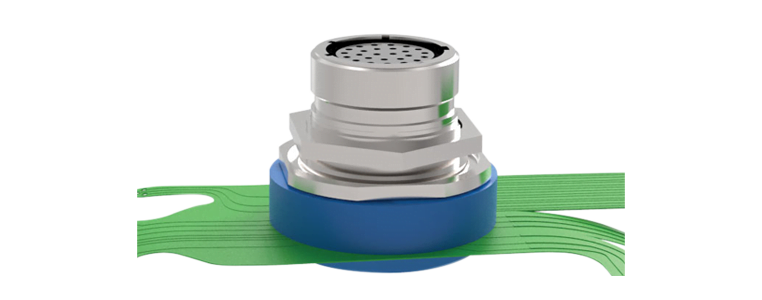

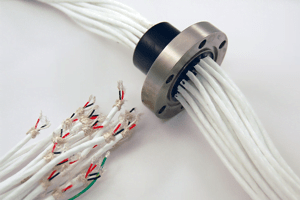

Hermetic flex circuit assembly

Hermetic flex circuit integrated with circular connector rendering

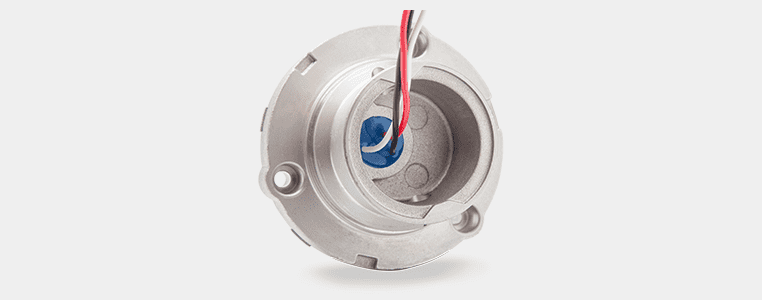

Sensor Hermetic Assembly

Hermetically sealed electrical feedthrough from PCB to cable in threaded housing

Hermetically Sealed Sensor Assembly

Hermetically sealed sensor assembly where the sensing element is exposed to the operating environment, but the housing and wire are hermetically sealed.

Hermetic Control Box Assembly

Hermetically sealed housing from circuit board to wire assembly. This assembly creates a plug-and-play electrical connection that is hermetically sealed and saves installation time. This is a common configuration in IoT devices.

Flex Circuit Sealed

Hermetically sealed flex circuit assembly with custom housing

Multi-flex hermetic feedthrough

Multi-flex hermetic feedthrough circuit with face seal housing and jam nut

Features

TECHNICAL ADVANTAGES

- Hermetic electrical feedthroughs with mounts and waterproof connectorization—including a hermetic equivalent to the IP-68, NEMA 6P-rated, Brad Harrison, and Woodhead design.

- Manufactured and approved for use in refrigerant equipment per UL 984, UL 207, CSA C22.2 No. 140.3 and CSA C22.2 No. 140.2 by UL file number SA10259.

- Compatible with common refrigerants and oils including: PEO oil, PVO oil, R12, R123, R134a, R22, R245FA, CO2 and others.

EXAMPLE APPLICATIONS

- Air conditioning charge sensor used to detect leakage of refrigerant.

- Hermetically sealed sensors requiring protection against humidity, moisture, and high-pressure wash-down

- In-tank hermetically sealed small refrigerant pump applications for pressure, temperature, and hermetically sealed pump power.

- Gasoline, LPG, CNG, LNG and biodiesel tank feedthroughs for in-tank pump power and sensors.

- DuctorSeal® vacuum penetration for kinetic energy recovery systems (KERS).

- PotCon® and StudSeal™ hermetic feedthroughs for on-road lithium liquid metal polymer batteries

- Hermetically sealed high voltage contactors

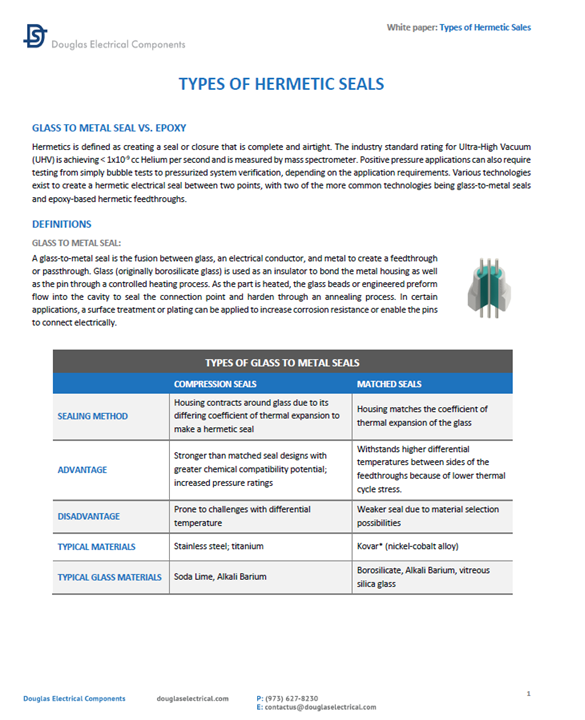

Documents

Literature & Whitepapers

Certificates & Standards

Related Products

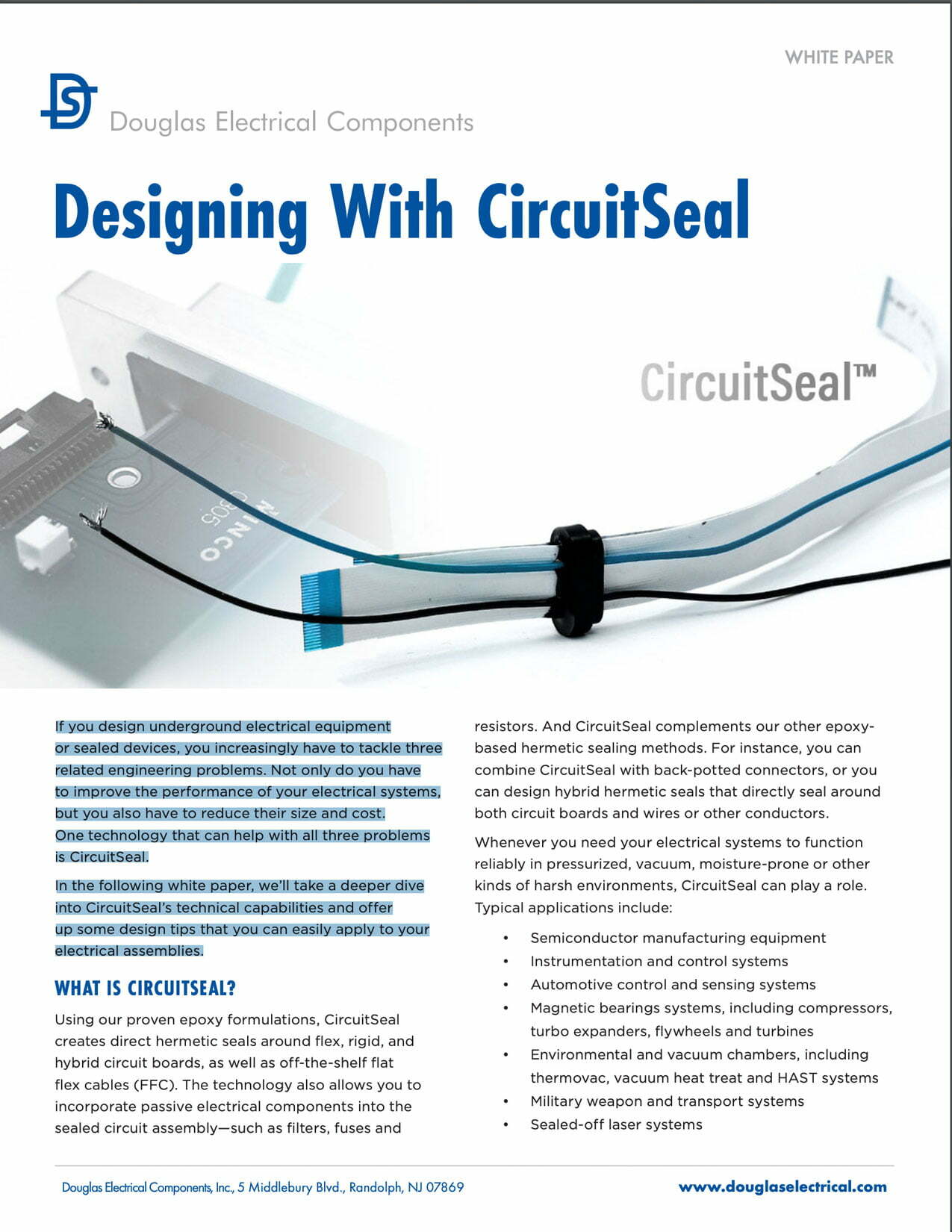

Hermetic Wire / Cable Feedthroughs

Create a high-density, hermetic wire or cable feedthrough using virtually any conductor

Hermetic Circuit Board Seals

Water-proof and hermetic electronic encapsulation of circuit board assemblies.

Hermetic Bulkhead Connectors

Hermetically seal the connector of your choice for bulkhead mounting.

Backpotted Connector Assembly

All the benefits of a hermetic connector with a custom mechanical interface.

Hermetic Backpotted Connector

Industry-leading made-to-order hermetic bulkhead connector assemblies

Radial O-ring Feedthroughs

High-pressure feedthrough capable of hermetic sealing

for various OEM applications

SAE Feedthroughs

Hermetically seal connectors, wires, cables, terminals, circuits and

optical fiber with an SAE mechanical interface.

Customer-Supplied Housing Feedthroughs

Create lightweight, low-profile hermetic assemblies using your existing housings and hardware.