In industries where precision and resilience are critical, such as aerospace and military technology, the demand for reliable, and safe interconnect solutions is paramount. Among these solutions, multipin feedthroughs play a vital role, ensuring seamless power and signal transmission through sealed enclosures. Douglas Electrical Components, known for its cutting-edge hermetic sealing technologies, offers a range of multipin feedthroughs designed for use in demanding environments, such as vacuum and high-pressure applications. Let’s explore what multipin feedthroughs are, the challenges they overcome, and their benefits.

What Are Multipin Feedthroughs?

Multipin feedthroughs are components that allow multiple electrical connections to pass through a sealed barrier while maintaining the integrity of the enclosure. They provide reliable, hermetically sealed connections for applications in vacuum environments, high-pressure systems, and harsh conditions, ensuring electrical continuity without leaks or contamination. As the pin count increases within a single feedthrough, there is a higher density of pin count, potentially reducing the number of feedthroughs required.

Multipin feedthroughs are components that allow multiple electrical connections to pass through a sealed barrier while maintaining the integrity of the enclosure. They provide reliable, hermetically sealed connections for applications in vacuum environments, high-pressure systems, and harsh conditions, ensuring electrical continuity without leaks or contamination. As the pin count increases within a single feedthrough, there is a higher density of pin count, potentially reducing the number of feedthroughs required.

Challenges in Vacuum and High-Pressure Environments

Vacuum and high-pressure environments present several challenges for electrical and signal connections. The operating and ambient temperatures impact feedthrough performance. The conductor type and distance between conductors can also factor into the multipin feedthrough design. Here are the three most common challenges

- Outgassing: Materials may release trapped gases under vacuum, potentially compromising system performance or contaminating sensitive environments. Multipin feedthroughs are constructed using materials and epoxy sealing techniques that minimize outgassing. At Douglas, we specify our epoxy as low-outgassing (0.25% TMA, 0.00% CVCM), with products deployed in UHV environments in some of the world’s most critical semiconductor processing equipment.

- Material Stress: Pressure differentials between the interior and exterior of a system can place immense stress on seals and materials. Hermetically sealed multipin feedthroughs maintain structural integrity under extreme conditions, providing dependable performance.

- Thermal Cycling: Systems subjected to repeated temperature changes can experience expansion and contraction, leading to potential connection failure. Multipin feedthroughs are designed to withstand such fluctuations, maintaining reliable performance. Douglas manufactures hermetic feedthroughs for various applications that experience thermal cycling, including feedthroughs in crogenic environments. It’s best to discuss this design consideration with a sales engineer to understand how to properly design the feedthrough.

List of Multipin Feedthroughs Available at Douglas Electrical Components

Douglas Electrical Components offers a comprehensive range of multipin feedthrough solutions, each tailored to specific needs and environments:

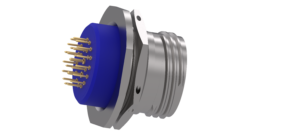

Hermetically sealed 38999 connectors

- Multi-Pin Mil-Spec Feedthroughs: These feedthroughs integrate MIL-spec connectors with backpotting and integral PCB pins, ensuring robust hermetic sealing and adherence to military specifications. Ideal for aerospace, defense, and critical systems, they offer superior environmental protection and longevity.

- Multipin Coaxial Feedthroughs: Hermetically sealed coaxial feedthroughs transmit signals in vacuum and pressurized environments with minimal loss, while providing high-frequency EMI shielding. They are suitable for vacuum chambers, control cabinets, and gloveboxes, supporting connectors such as SMA, BNC, and other high-frequency configurations. Multipin coaxial feedthroughs are possible as well as combining multiple connection points within the same flange assembly.

- Multipin Electrical Feedthroughs: These feedthroughs, featuring waterproof connectors with NPT interfaces and wire leads, provide ruggedized protection against extreme environments. Their design ensures moisture resistance, durability, and electrical integrity, making them suitable for harsh industrial applications.

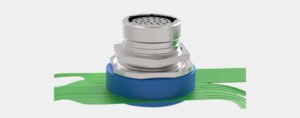

9 position hermetic micro-D connector feedthrough

- Hermetic Circular Multipin Connectors: Hermetically sealed circular connectors and NPT connector offer versatile solutions for power and signal transmission in harsh conditions. These circular multipin connectors offer versatile hermetic sealing for industries such as aerospace, industrial machinery, and underwater applications. Their circular form factor facilitates easy integration while maintaining robust sealing capabilities. Circular multipin feedthroughs can include MIL-spec rated connectors as well as more industrial metric connectors such as M12 and M23. Additionally, subsea and push-pull designs are available for hermetic sealing.

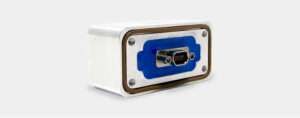

- Hermetic Rectangular Multipin Connectors: Hermetic Rectangular multipin connectors provide a space-saving design for data transmission and industrial control applications. Configurations like dual D-sub hermetic connectors comply with MIL-DTL-24308 and MIL-DTL-83513 standards, ensuring performance reliability even in demanding conditions.

Key Features of Using Multipin Feedthroughs for Vacuum and High-Pressure Applications

Multipin feedthroughs offer numerous features that make them ideal for demanding applications, including:

- Hermetic Sealing Technology: Ensuring a hermetic seal is critical for maintaining vacuum integrity and protecting sensitive systems from environmental contaminants. Douglas Electrical Components employs proprietary epoxy sealing methods to achieve superior sealing performance, even under extreme conditions.

- Durability and Mechanical Integrity: Multipin feedthroughs are built to endure high pressure and mechanical stress, providing reliable performance in applications such as oil and gas exploration, industrial machinery, and hydraulic and pneumatic systems.

- Customization Options: The versatility of multipin feedthroughs extends to customization. Douglas Electrical Components can tailor designs to specific industry needs, including unique mechanical interfaces, electrical connections, and sealing configurations. Due to our manufacturing process employing a relatively low process temperature cure, our hermetic feedthroughs can bond directly to various mechanical and electrical interfaces rated for those temperatures.

- Pressure Tolerance and Adherence to Safety Standards: Multipin feedthroughs are rigorously tested to meet or exceed industry safety standards. They are capable of handling substantial pressure differentials, ensuring consistent performance in high-pressure applications like gloveboxes, semiconductor manufacturing, and hazardous environments.

- Integrate Multipin Connectors into Wire Feedthroughs: Douglas can add connectors to the ends of hermetic wire feedthroughs to give the plug and play flexibility of a multipin connector with the design flexibility of having wire within the assembly. The can help with increasing feedthrough density and managing through challenging operating conditions.

Why Choose Douglas Electrical Components for Multipin Feedthrough Solutions

Douglas Electrical Components is a leading provider of customized, high-performance multipin feedthroughs designed to meet the most demanding conditions. Our advanced hermetic sealing technology allows us to seal virtually any multi-pin connector on the market, offering flexible solutions with integrated electrical connections and custom mechanical interfaces. Whether you need standard, semi-custom, or fully custom designs, we deliver multipin hermetic feedthroughs tailored to your exact specifications. Our LEAN manufacturing process, robust supply chain, and efficient design capabilities enable us to ship feedthroughs in the desired configuration and quantity within 4-6 weeks, AAO.

Our expert engineering team works closely with clients to develop customized solutions that meet the highest industry standards. Partner with a sales engineer today to begin designing your multipin feedthrough solution.