Incorporating sensing elements into sealed electrical assemblies

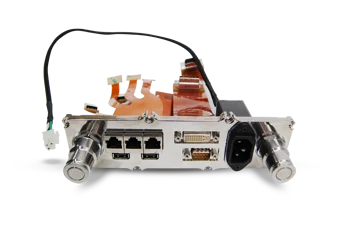

One defining characteristic of CircuitSeal™ technology is its design flexibility. Not only can CircuitSeal work with many different types of circuit boards, but it can also integrate related electrical components to create a fully-functional, hermetically sealed electronics assembly. One such component is a sensing element.

CircuitSeal assemblies routinely incorporate a sensing and signal conditioning elements of one type or another. Using epoxy, we can directly seal around pressure, temperature, humidity, proximity and other types of sensors in addition to capacitors, resistors, switches and other signal conditioning components. A complete CircuitSeal sensing assembly would also include a circuit board, wire harness, and a fitting or housing.

The resulting sensing assemblies offer many advantages:

- Improved Reliability. In harsh environments, sensor assemblies can have a very short working life. CircuitSeal can protect the sensing electronics from moisture, chemicals, excess pressure, thermal expansion, shock and vibration. CircuitSeal’s sealing performance is fully hermetic, with leak rates below 1×10-8 cc-He/sec.

- Reduced Size, Better Fit, Less Weight. CircuitSeal sensing assemblies are compact. They allow creative packaging of the sensing element and its circuit board to save space. In one recent assembly, for example, we packaged a humidity sensor and a long, thin circuit into a small threaded fitting. In general, CircuitSeal sensing assemblies are typically at least 30% smaller than conventional wire and cable sealed sensing assemblies. However, as conductor count increases so will space savings.

- Lower Cost. CircuitSeal sensing assemblies also cost less to produce, install and replace than sensing assemblies with a separate wire feedthrough. Typical cost reduction figures can vary, but it’s not uncommon to reduce costs by 50% or more in sensor applications.

- Minimized Connection Points. By integrating signal conditioning and sensing into the hermetic feedthrough customers have seen an overall reduction in required cable harnesses which can further reduce complexity, cost and size.

The applications for sealed circuit assemblies obviously involve the use of a sensing element in vacuum or pressure chambers of one kind or another. Many CircuitSeal sensing assemblies have historically gone to work in space simulation or semiconductor equipment but applications continue to expand with frequent use in military applications. Increasingly, though, these sensing assemblies are also finding a home in vacuum applications where signal conditioning elements prone to outgassing need to be sealed inside epoxy to protect costly semiconductor wafers from contamination.

To learn more about CircuitSeal sensing assemblies, download our white paper.