All gloveboxes need to transmit power, signal, and/or data from the outside, while preserving the controlled internal environment. Standard size ports provide space for electrical pass throughs but require a hermetic seal to maintain the barrier. Epoxy feedthrough connector designs have the flexibility to meet these requirements and work with existing ports.

When considering power, it’s useful to have a quick connect design that is reliable and safe. Three popular options are IEC C19, the NEMA 15 series, and the NEMA 20 series. Hermetic poxy solutions can be designed using all standard plug and receptacle options, allowing engineers to select solutions that meet specific voltage, current, and safety needs. This article focuses on the the most commonly used solutions.

Key Takeaway: Match voltage, current, and safety requirements with standard IEC and NEMA plugs and receptacles to create quick connect power solutions for gloveboxes.

Electrical Standards: NEMA and IEC

In glovebox applications, electrical standards determine not only voltage and current capabilities, but also connector size and the number of connectors and/or conductors that can fit into a single feedthrough for a glovebox port. NEMA connectors are power plugs and receptacles that use standards set by the US National Electrical Manufacturers Association. There are multiple unique configurations based on voltage, electric current capacity, and grounding system. They are named using the following code: (L)X-X(P/R). The “L” indicates whether there is a twist-lock, which is used for heavy industrial and commercial equipment to protect against accidental disconnection. The first “X” is a number for the voltage rating, while the second “X” is the number for the amperage rating. The final identifier is either “P” for plug or “R” for receptacle.

Another major standard is IEC, the International Electrotechnical Commission. The organization develops and publishes international standards for a wide range of electronic technologies, which includes power connectors. This creates standardization, safety and compatibility with existing circuits worldwide. IEC 60320 covers non-locking power supply cords that link to electrical appliances.

In essence, the decision to seal a NEMA or IEC plug depends on where you intend to seal the power connection – IEC focuses on the device side, while NEMA plugs focus on the AC/outlet connection.

C19 – Connecting High Power Devices

The IEC C19 plug is widely used across a variety of sectors. Its ability to support heavy electric currents up to 16 amps means that they are used for industrial applications and fabrication machines as well as high-power computing devices that require reliable and steady power connections. When this equipment is placed within a glovebox, a hermetic feedthrough that combines the C19 power cord with a face seal housing provides continued reliable performance while maintaining the glovebox barrier.

NEMA 15 – The Familiar Solution

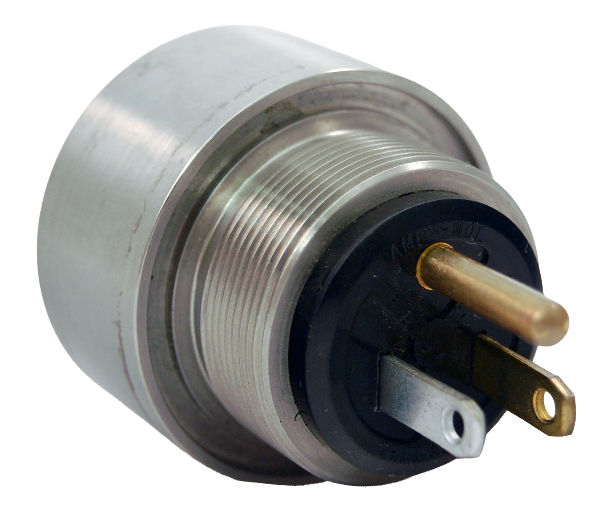

NEMA 15 plugs are the most common configurations people see in the US. The NEMA 1-15P is the two prong plug that people are familiar with. The NEMA 5-15P is a standard, 15 amp, 120V household plug used for general appliances and devices. It differs from the 1-15P in the inclusion of a grounding prong. A NEMA 6-15P goes slightly further because it is a 15 amp plug that’s rated for 240V. The 6-15P is the most popular choice for commercial and industrial use because it handles higher voltage ratings. There is a standard vacuum convenience feedthrough that combines a NEMA 5-15 plug and receptacle with a KF40 flange, but it can be customized to better fit your application.

NEMA 20 – A Higher Current Option

Another popular choice for industrial and other demanding applications is the NEMA 20 series because it has a maximum current rating of 20 amps. The NEMA 5-20P is a grounded plug that has a maximum voltage rating of 120V, and is used where there are higher load devices. The NEMA 6-20P is more popular because it combines a maximum voltage of 250V with the 20 amp maximum current rating. These secure power delivery in commercial, industrial, and research environments. NEMA 20 plugs and receptacles are larger than NEMA 15 ones, which means you will need to use a housing larger than a KF40.

NEMA Twist Locks – Increased Reliability

As mentioned earlier, NEMA plug and receptacle codes include an optional L prefix for twist-locks. It is possible to choose NEMA L5-15, NEMA L6-15, NEMA L5-20, and NEMA L6-20 plugs and receptacles for hermetic sealing. These versions provide an additional element of security with the twist-lock, reducing the possibility of accidental disconnection. Gloveboxes containing hazardous materials like nuclear radiation might benefit from this additional level of security, reducing the possibility of costly downtime.

Feedthrough Designs for C19, NEMA 15, and NEMA 20

Whatever way you choose to send power into your glovebox, hermetic feedthroughs provide reliable performance, prevent glovebox leaks, and stop ingress from the outside environment. Glovebox port sizes, the device(s) you need to power, and the arrangement of the glovebox environment all influence overall feedthrough design. Douglas Electrical Components designs solutions that address all requirements, potentially combining power, signal, and/or data into one feedthrough. The flexibility of these custom feedthroughs makes it easy to use IEC and NEMA standard plugs and receptacles, such as C19, NEMA 15, and NEMA 20 standards to bring power into your glovebox.

Ready to get started? Get a free hermetic design consultation and start building your feedthrough today.