As global weather patterns grow unpredictable, power transmission and distribution (T&D) networks face operational risks due to weather events, including flooding, hurricanes, wildfires, and extreme temperature fluctuations. In fact, 80% of all major US power outages from 2000 to 2023 were due to weather (Climate Matters, 2024). The reliability of T&D networks is challenged by these conditions affecting their components, particularly switchgear, which ensures the safe operation of electricity grids. Leveraging insights from industry trends and Douglas Electrical Components’ expertise in epoxy-based hermetic feedthroughs, this white paper focuses on the growing importance of building resilient switchgear feedthroughs that enhance grid reliability, with a focus on hermetic sealing solutions.

The Role of Hermetic Feedthroughs in Enhancing Switchgear Resilience

As electricity demand continues to increase and climate-related disruptions become more frequent, the power and utilities sector is at a critical juncture. Deloitte’s 2025 Power and Utilities Industry Outlook highlights that many utilities are prioritizing grid hardening and resilience to address the growing frequency of extreme weather events. As a part of this shift, critical components within the transmission and distribution ecosystem, particularly switchgear, must evolve to maintain system reliability and operational continuity to face these challenges.

Hermetically sealed feedthroughs play an essential role in this context. They provide reliable power to switches, sensors, and other control equipment within the gas-filled enclosure. Hermetic feedthroughs also help prevent environmental ingress that can compromise the performance of switchgear in unpredictable weather while ensuring the containment of dielectric gases necessary for safe operation. This white paper examines the role of switchgear feedthroughs in grid resilience and proposes design considerations for extreme weather applications.

The Growing Impact of Unpredictable Weather on T&D Infrastructure

- Escalating Weather Risks: Leader (2020) highlights the fact that environmental risks, such as hurricanes, wildfires, floods and heatwaves, are disrupting power delivery, resulting in costly damages. He argues not only for microgrids, but also resilience solutions including moving T&D infrastructure underground and storm hardening substations and feeders.

- Grid Hardening Imperative: Utilities are investing in storm hardening and weather risk management strategies, such as reinforced infrastructure and proactive maintenance to minimize outages and downtime that cost billions of dollars annually (Deloitte, 2025).

- Switchgear’s Critical Role: Switchgear manages power flow and protects T&D systems against faults. Failure can happen due to environmental ingress, gas leaks, and/or insulation failure, disrupting entire grids.

- Regulatory and Environmental Shifts: Due to sulfur hexafluoride (SF6)’s high global warming potential, the industry is moving to eco-friendly insulating gases like dry air, CO2, or fluoroketones. Epoxy-based hermetic feedthroughs offer the flexibility to create reliable seals for SF6 as well as alternative gas types, ensuring performance and environmental compliance.

Why It Matters

Unpredictable weather amplifies the need for resilient switchgear to maintain grid reliability. Feedthroughs, with their ability to provide hermetic seals across insulating gases, are critical in preventing environmental damage and system downtime. These feedthroughs serve as an important line of defense between internal components and external environments. They help prevent moisture, dust, and gas leaks that may compromise the performance of switchgear.

The Critical Role of Switchgear in Grid Resilience

Switchgear remains a cornerstone of grid stability in T&D networks. As switchgear manages power flow and protects systems from faults, it must operate reliably under harsh environmental conditions to ensure safety and prevent outages. This section provides a detailed explanation of switchgear’s role in modern electrified grids and the environmental threats that jeopardize its integrity, emphasizing the high stakes of failure in today’s climate-driven landscape.

Switchgear in the Age of Electricity

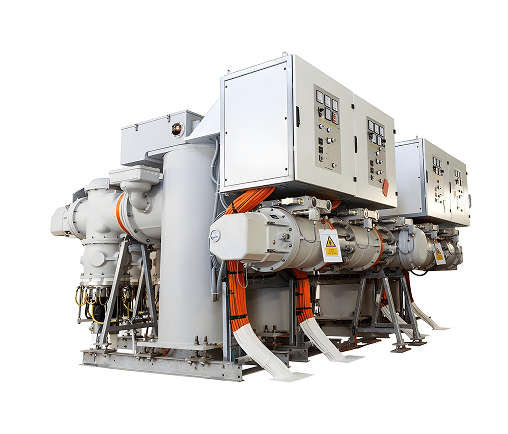

Switchgear is a critical component in T&D systems. It features an assortment of circuit protection devices, including switching devices (e.g. circuit breakers, switches, and fuses), measuring devices (e.g. current and voltage transformers), protection and control devices (e.g. relays), and conductors (e.g. buses and connections) to carry power between points. These circuit protection devices are housed in gas-insulated and metal-clad enclosures. Thus, switchgear is designed to protect, control, and isolate electrical equipment in substations, industrial facilities, and underground networks.

According to IEA Executive Director Fatih Birol, we’re moving into the Age of Electricity, a new global energy system incorporating clean sources of electricity (IEA, 2024). Factors including rising demand for data centers, renewable energy systems, and electric vehicles drive this shift. High-voltage (above 36 kV) and medium-voltage (1-36kV) switchgear ensure stable operation across applications like renewable energy integration, underground vaults, and urban substations.

Alongside the push for renewable energy has been support for more climate-friendly switchgear. Typically, switchgear was insulated with sulfur hexafluoride (SF6), which is a potent greenhouse gas. To reduce potential greenhouse gas emissions and meet climate change goals, many in the industry are transitioning to eco-friendly alternatives, such as dry air or fluoroketones

Switchgear reliability across diverse operating conditions is non-negotiable. Any failure of switchgear components may trigger cascading outages, disrupting power supply to thousands of customers and incurring significant economic losses. For instance, the failure of a single substation may lead to hours or days of downtime, with costs sometimes escalating to millions depending on the scale of the outage (Deloitte, 2025). Therefore, switchgear must be engineered for resilience, utilizing components like hermetic feedthroughs to ensure uninterrupted performance

Environmental Threats to Switchgear Integrity

Switchgear installations, whether above ground or underground, are subjected to several environmental stressors due to increasingly unpredictable weather patterns. These threats challenge the integrity of critical components, including feedthroughs. They can compromise grid reliability if not addressed through strategic designs. Key environmental threats that risk switchgear integrity include:

- Salt Spray in Coastal Environments: Coastal substations and offshore renewable energy systems are exposed to salt-laden air, which leads to corrosion of metal components. Over time, salt spray can penetrate non-hermetic feedthroughs, leading to insulation failure and electrical arcing.

- Freeze-Thaw Cycles in Northern Regions: Switchgear in colder climates is exposed to freeze-thaw cycles, where temperatures can drop to -40°F or lower. These cycles cause seals to contract and thermally expand, which may lead to cracks. Cracks allow moisture ingress, potentially causing further damage to components.

- Wildfires in Dry Zones: Switchgear operating in wildfire-prone regions may be exposed to exceedingly high temperatures. While epoxy feedthroughs in switchgear cannot survive being within an actual wildfire, those nearby can handle temperatures up to 350°F and block particulate matter and ash spread beyond the site of the wildfire. This protects insulation materials and ventilation systems, decreasing the risk of failure

- Flooding in Low-Lying Areas: Switchgear installations in coastal and urban areas are vulnerable to submersion risks from storm surges, hurricanes, or heavy rainfall. Water ingress into switchgear enclosures can cause corrosion, gas leaks, and short circuits, leading to failure.

- UV Resistance in Exposed Cables: Switchgear cables exposed to sunlight over time may experience degradation from UV radiation, which weakens insulation materials. This can lead to insulation failure, especially in outdoor applications, where prolonged exposure to UV rays compromises cable durability and safety.

The costs of switchgear failure are substantial:

- Downtime: Weather-related outages can disrupt power supply to residential, commercial, and industrial customers for several hours and days. For example, hurricane-induced outages in 2024 resulted in up to $2.9 billion in lost revenue and repairs for

- Repair Costs: Replacing damaged switchgear components, including feedthroughs, is expensive. They may cost anything between a few hundred to several thousand dollars, depending on the design and severity of damage. These costs are amplified by labor-intensive repairs in remote or hazardous locations (Switchgear Costs, 2025).

- Safety Risks: Faulty switchgear can lead to serious safety risks, including electrical fires, arc flashes, or equipment explosions, which can endanger utility workers and nearby communities.

- Environmental Impact: Failures in gas-insulated switchgear can lead to leaks of insulating gases such as SF6, a potent greenhouse gas. Even when alternatives are used, uncontrolled releases may require costly containment, cleanup, or regulatory fines. While air-insulated switchgear avoids these gas-related risks, both types share the same operational purpose, and the choice of insulation medium can influence both environmental footprint and compliance obligations.

Why It Matters

The performance of switchgear under extreme weather is critical to grid resilience. Environmental threats like salt spray, freeze-thaw cycles, wildfires, and flooding underscore the need for robust, hermetically sealed feedthroughs that prevent ingress and maintain electrical and mechanical integrity. By addressing these challenges, utilities can reduce outage risks, enhance safety, and lower maintenance costs, aligning with industry trends toward grid hardening and sustainability.

Challenges in Switchgear Design for Extreme Weather

As power systems are increasingly deployed in environments ranging from coastal regions to remote deserts, the switchgear components, especially feedthroughs, must be carefully engineered to ensure safety, reliability, and longevity. Designing switchgear for extreme weather presents a complex set of engineering challenges.

- Environmental Stressors: Switchgear operates in environments marked by extreme temperature fluctuations from -100°F to 350°F, UV, and high humidity (up to 100% RH). In coastal and flood-prone areas, the switchgear may be exposed to flooding, salt spray in coastal regions, which can degrade seals, conductors, and insulators.

- Electrical Performance Under Stress: Medium- and high-voltage switchgear require robust insulation to prevent arcing, short circuits, or dielectric breakdown, particularly in wet or contaminated environments. Thus, switchgear operated in these environments requires superior insulation and component design to ensure stability and operational safety.

- Mechanical and Thermal Loads: Feedthroughs within switchgear are exposed to thermal expansion/contraction, mechanical vibrations from wind or equipment, and external environmental pressures, such as submersion conditions exceeding IP68/69 levels. The internal pressure may be minimal due to the insulating medium; the cumulative external stresses may lead to seal cracks or conductor fatigue over time.

- Long-Term Durability: Long-term reliability of switchgear components like feedthroughs is crucial in remote or mission-critical installations where maintenance is logistically challenging and expensive. Therefore, feedthroughs must withstand exposure to harsh environments for decades.

- Gas Compatibility and Hermetic Sealing: Feedthroughs must maintain hermeticity across a range of insulating gases, including SF6 alternatives, to support the industry’s sustainability goals.

Why It Matters

Feedthroughs must be engineered to address these multifaceted challenges, ensuring switchgear reliability in diverse applications, from urban substations to remote renewable energy installations.

The Role of Hermetic Feedthroughs in Switchgear Resilience

Rising demand and increasingly volatile climates have led to power transmission system development, where the reliability of switchgear components is mission-critical. Here hermetic feedthroughs play a pivotal role in maintaining performance integrity under extreme conditions

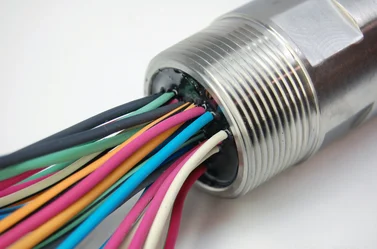

- Function of Hermetic Feedthroughs: Hermetic feedthroughs create a gas-tight, moisture-proof pathway for electrical conductors passing through gas-insulated cavities. This pathway protects internal switchgear components, such as transformers, sensors, and other critical equipment, from environmental ingress while ensuring insulation and gas retention.

- Epoxy-Based Hermetic Seals: Douglas Electrical Components’ proprietary epoxy seals help achieve true hermetic performance, withstanding vacuum levels as low as 1×10⁻⁹ Torr and pressures up to 15,000 psi, ensuring long-term reliability. Their flexibility enables robust sealing for SF6 and SF6 alternatives, such as dry air, CO2, and fluoroketones. Douglas Electrical employs a NASA-certified low-outgassing, epoxy tested per ASTM E-595-93 (0.33% TML. 0.00% CVCM).

- Customization and Flexibility: Epoxy technology offers extreme customizability of feedthroughs to meet different application requirements. Epoxy technology enables the creation of feedthroughs for various environments from cryogenic temperatures to 200°C. Each feedthrough can integrate pins, circuits, or wire harnesses, supporting wire gauges from 38 AWG to 500 MCM, and conductor counts from single-wire to over 3200 conductors in a single unit.

Applications Across Industries

- Medium/High-Voltage Switchgear: Ensures reliable power distribution in substations and industrial facilities.

- Underground/Submersible Systems: Protects against flooding in urban vaults or coastal installations.

- Renewable Energy: Supports gas-tight integrity in wind, solar, and energy storage systems.

- Military/Aerospace: Delivers 100% uptime in extreme environments, from arctic cold to desert heat.

Why It Matters

Hermetic feedthroughs, with their ability to seal effectively across all insulating gases, enable switchgear to maintain performance in extreme weather and support the transition to sustainable T&D systems.

Advanced Design Considerations for Reliable Switchgear Feedthroughs

Six key design principles enable switchgear feedthroughs to perform reliably in challenging real-world applications.

1. Material Selection for Harsh Environments

- Epoxy Seals: Use chemically inert, high-strength epoxy to resist corrosion in high-humidity, salt-spray, or chemically aggressive environments (e.g., coastal or industrial settings). Epoxy’s versatility ensures compatibility with SF6 and SF6 alternative gases, including dry air, CO2, and fluoroketones.

- Conductor Materials: Choose copper or copper alloys for optimal conductivity and corrosion resistance. When additional protection is required coatings like tin or gold can enhance durability in high-moisture or high-salinity environments.

- Gas Compatibility: As switchgear transitions to alternative gases, designing seals to maintain hermeticity across a range of insulating gases becomes essential.

2. Mechanical Robustness for Real-World Stresses

- Thermal Cycling: Feedthroughs may be subjected to temperature ranges between -100°F to 350°F. Design for thermal expansion/contraction to prevent seal cracking, using flexible epoxy formulations that maintain integrity across a wide temperature range.

- Vibration Resistance: A switchgear operating in industrial environments often faces mechanical stress from seismic activity, wind, or machines nearby. To mitigate mechanical failure, incorporate strain relief and robust mounting.

- Pressure Endurance: Engineer feedthroughs to withstand external pressure differentials from vacuum to 15,000 psi, critical for submersible or high-altitude applications where slight vacuum conditions are present.

3. Electrical Insulation for Adverse Conditions

- High-Voltage Rating: Advanced epoxy composites help prevent electrical breakdowns. Use materials with high dielectric strength (e.g., epoxy with dielectric constants >3.5) to prevent breakdown in medium/high-voltage systems.

- Conductor Spacing: Insulation performance may be compromised in environments with humidity or contaminants. Optimize spacing to minimize arcing risks, especially in humid or contaminated conditions.

- Insulation Testing: Conduct rigorous partial discharge and hipot testing to ensure insulation integrity under extreme conditions.

4. Submersion and Ingress Protection

- Waterproof Connectors: Ingress protection is paramount in flood-prone or underground installations. Integrate IP68-rated connectors and sealed wire harnesses for flood-prone installations. Test for IP68 or higher ingress protection ratings.

- Sealing Redundancy: Redundancy is the key. Use multi-layer sealing (e.g., epoxy plus O-rings) to enhance submersion resistance beyond IP68 in underground or coastal switchgear.

- Testing Standards: Validate designs against IEC 60529 (IP ratings) and MIL-STD-810 for environmental durability.

5. Scalability and Customization

- Modular Designs: Offer configurable feedthroughs to support varying conductor counts, wire gauges, and mounting options. This adaptability helps streamline integration across a wide range of switchgear architecture.

- Rapid Prototyping: Leverage in-house design and testing to deliver tailored solutions for unique project requirements, from single-piece to high-volume OEM production.

- System Integration: Embed circuits, sensors, or harnesses directly into feedthroughs to streamline switchgear assembly and reduce points of failure.

6. Future-Proofing for Climate Trends

- Wildfire Mitigation: Feedthroughs must be resistant to heat and airborne particles in dry and fire-prone zones. Design for heat and dust resistance to protect switchgear in dry, fire-prone regions by using high-heat-rated materials and filtered enclosures.

- Flood Resilience: Rising sea levels and severe weather events demand feedthroughs that can perform even when submerged. Prioritize submersion-proof designs for urban and coastal areas where submersion due to environmental issues is common.

- Temperature Extremes: Engineer for broader temperature ranges to accommodate increasing heatwaves and cold snaps.

Why It Matters

These advanced considerations ensure feedthroughs meet the evolving needs of T&D systems, enhancing grid resilience, reducing maintenance costs, and supporting sustainability through flexible sealing for various insulating gases.

Case Studies and Real-World Applications

The following case studies demonstrate how epoxy feedthrough solutions by Douglas are solving real-world challenges across industries.

Underground Distribution in Urban Centers

- Scenario: A major utility operating in a flood-prone city faced recurring issues with water infiltration into underground switchgear. These conditions frequently resulted in service interruptions and high maintenance costs.

- Solution: Douglas supplied epoxy feedthroughs engineered with advanced sealing capabilities that exceeded IP68 performance, ensuring both gas-tight reliability as well as waterproofing other critical electronics even under extended submersion.

- Impact: This upgrade helped reduce outages, improve maintenance costs, and support smart grid reliability.

Renewable Energy Storage in Coastal Regions

- Scenario: A solar energy storage system in a coastal area was exposed to salt spray, high humidity, and temperature extremes, which risked the integrity of switchgear.

- Solution: Douglas developed custom feedthroughs with corrosion-resistant conductors and epoxy seals. These units helped protect against environmental ingress, while ensuring gas retention for SF-6 alternative fluoroketone insulation.

- Impact: This upgrade helped extend the system’s lifespan and reduce maintenance needs. The facility maintained reliable integration into the renewable energy grid.

Why It Matters

These case studies illustrate how custom feedthrough designs address specific weather challenges, delivering measurable benefits across utility, renewable, and mission-critical applications. Whether combating floods, corrosion, heat, or dust, each solution was developed with specific environmental challenges in mind. The measurable outcomes are fewer outages, longer service life, and lower maintenance costs, which highlight how advanced materials and precision design translate into real-world performance, across a range of industries and applications.

Industry Trends and Future Outlook

As the energy landscape rapidly evolves, utilities are reimagining how they build and maintain a resilient and sustainable infrastructure. Several key trends are shaping the future of T&D systems and feedthroughs are playing a pivotal role in this transition.

- Grid Hardening Investments: Utilities are increasing spending on storm hardening, with a focus on moving key elements underground and upgrading substations to reduce storm-related outages(Sharpless & Byrne, 2024).

- Electrification and Demand Growth: A new ICF study (Batra et al., 2025) projects US electricity demand to increase 25% by 2030 and 78% by 2050 compared to demand in 2023. This requires reliable, resilient switchgear to help keep the electrical grid running.

- Sustainability Push: The phase-out of SF6 drives innovation in feedthroughs, with epoxy seals offering the flexibility to seal SF6 safely along with eco-friendly insulating gases, aligning with global decarbonization goals.

- Proactive Resilience Strategies: Utilities are adopting predictive maintenance and weather risk management to preempt outages, with feedthroughs playing a critical role in long-term durability.

Why It Matters

Epoxy feedthroughs, with their ability to provide reliable seals for a range of insulating gases, play a critical role in aligning switchgear with industry trends. This adaptability allows utilities to meet rising demand and climate challenges while maintaining reliability.

Conclusion

As climate change intensifies weather-related challenges, resilient switchgear feedthroughs are essential for ensuring the reliability of T&D networks. By prioritizing hermetic sealing, material durability, and flexible designs compatible with both SF6 and SF6 alternatives, utilities can mitigate risks from environmental stressors and support the transition to sustainable, high-demand grids. Epoxy-based hermetic feedthroughs offer a proven, versatile solution, delivering unmatched performance in harsh conditions.

Utilities, OEMs, and system integrators must prioritize advanced feedthrough solutions to future-proof switchgear against extreme and unpredictable weather. Douglas Electrical Components offers standard and customized hermetic feedthroughs designed to perform under adverse weather conditions, supporting sustainable switchgear designs and long-term operational integrity. Connect with our engineering team today to see how we can support your grid resilience initiatives.

References

- Batra, L., Harris, D., Katsigiannakis, G., Mackovyak, J., Parmar, H., Scheller, M. (2025). Rising current: America’s growing electricity demand. https://www.icf.com/insights/energy/impact-rapid-demand-growth-us

- Climate Matters (2024, April 24). Weather-related power outages rising. https://www.climatecentral.org/climate-matters/weather-related-power-outages-rising

- Deloitte. (2025). 2025 Power and utilities industry outlook. Retrieved from https://www.deloitte.com/gr/en/Industries/power-utilities-renewables/perspectives/2025-power-and-utilities-industry-outlook.htmlIEA (2024, Oct. 16). Geopolitical tensions are laying bare fragilities in the global energy system, reinforcing need for faster expansion of clean energy. https://www.iea.org/news/geopolitical-tensions-are-laying-bare-fragilities-in-the-global-energy-system-reinforcing-need-for-faster-expansion-of-clean-energy

- Leader, J. (2020). A process for planning and deploying microgrids for community resilience. T&D World. https://www.tdworld.com/

- Reuters (2024, Nov. 7). Duke Energy sees up to $2.9 bln in hurricane restoration costs. https:// www.reuters.com/business/energy/duke-energy-sees-up-29-bln-hurricane-restoration-costs-2024-11-07/distributed-energy-resources/energy-storage/article/21133677/microgrids-for-community-resilience

- Sharpless, K., & Byrne, C. (2024, Dec. 3). Powering up resilience: Transforming the grid with technical advancements and proactive strategies. T&D World. https://www.tdworld.com/transmission-reliability/article/55246921/powering-up-resilience-transforming-the-grid-with-technical-advancements-and-proactive-strategies

- Switchgear Costs (2025). FasterCapital. Retrieved July 1, 2025 from https://fastercapital.com/term/switchgear-costs.html

About Douglas Electrical Components

Douglas Electrical Components is a trusted partner for mission-critical hermetic feedthrough solutions. We help utilities, OEMs, and renewable energy providers stay ahead of evolving challenges.

We have over three decades of experience in epoxy-based hermetic seals for switchgear, with a track record in utility and renewable applications.

- Certifications: Our ISO 9001:2015, ISO 14001:2015 and ATEX/IECEX certifications ensure quality and compliance with global standards. These certifications reflect our commitment to delivering feedthroughs and components that perform consistently in critical applications.

- Rapid Prototyping and Testing: Our in-house design and testing capabilities accelerate the delivery of custom solutions, from concept to production.

- Scalable Production: We support projects from single-piece prototypes to high-volume OEM runs with consistent quality. Our scalable production model ensures consistent quality at every stage, supporting both agile development and long-term supply chain stability.

- Industry Leadership: Douglas is trusted by leading utilities and OEMs for field-proven solutions that enhance grid resilience.