Predictive maintenance and condition-based monitoring (CBM) are essential strategies for ensuring equipment safety, reliability, and efficiency. These approaches use measurements and data to assess the condition of equipment, prevent failure, and downtime, and optimize operational costs. Traditionally, condition-based monitoring involved non-invasive measurements, scheduled tests, and visual inspections performed at pre-set intervals. However, the Industrial Internet of Things (IIoT) has changed it all. It comprises an ecosystem of sensors, devices, applications, and networks that collect, monitor, and analyze data from different industrial equipment. Although IoT has made remote monitoring of assets possible, it comes with its own operational challenges when implemented in different industrial environments. This post offers an overview of CBM, how IIoT contributes to CBM and the importance of hermetic sealing.

Understanding Condition-Based Monitoring and Its Benefits

Condition-based monitoring is a type of predictive maintenance that monitors the real-time condition of equipment to decide the mode of maintenance. CBM data informs users to perform maintenance when specific indicators show a decrease in performance. For instance, maintenance should be performed when a certain vibration level is reached, or a certain parameter falls out of range. The following are a few popular types of condition-based monitoring techniques performed:

- Vibration Analysis

- Oil Analysis

- Temperature Measurements

- Acoustic Analysis

- Motor Circuit Analysis

- Electrical Monitoring

- Electromagnetic Measurement

- Radiation Analysis

- Laser Interferometry

All of the above condition-based monitoring techniques help maintenance, operations, asset management, and standard groups to understand quirks of each equipment. Condition-based monitoring helps to:

- Increase uptime

- Reduce downtimes

- Decrease maintenance costs

- Increase asset life

- Reduce collateral asset damages

- Prioritize and plan work orders effectively

- Improve asset and worker’s safety

- Improve workplace efficiency

How IIoT is Transforming Condition-Based Monitoring

IIoT integration has enhanced the capabilities of condition-based monitoring. It leverages wireless sensors and cloud computing to collect and analyze data from various industrial equipment in real time. IIoT also makes remote monitoring possible in industries with widely dispersed assets, such as oil and gas, manufacturing, transportation, and power generation.

Unlike the earlier sensors, these wireless sensors have fewer installation requirements. They reduce the need for complex wiring and enable quicker deployments in difficult-to-reach or hazardous locations. With IoT, real-time data is securely transmitted to centralized monitoring systems. The insights from data sets are decoded by machine learning algorithms and analytics to predict failures, detect anomalies, and optimize maintenance schedules.

Challenges in IIoT Condition-Based Monitoring

According to various reports, IIoT condition-based monitoring can reduce equipment outages by 50% and reduce maintenance costs by 25%. While the benefits are clear, there are several challenges, too. Although sensors and electronic components used during monitoring are designed for consistent performance in different industrial environments, they may fail due to exposure to high pressures, extreme temperatures, and corrosive substances. This is where hermetic sealing can make a difference; they protect sensitive sensors and other electronic components from harsh conditions, ensuring long-time reliability and performance. The next section discusses hermetic sealing in IIoT in detail.

The Role of Hermetic Sealing in Improving Condition-Based Monitoring Equipment

Hermetic sealing creates an airtight, moisture-proof seal that protects electronic components, sensors, and connectors from environmental factors. This sealing offers a layer of protection to condition-based monitoring equipment operating in challenging conditions, such as extreme temperatures, high pressures, corrosive environments, or underwater applications. Here are some key roles of hermetic sealing in enhancing the lifespan of CBM equipment:

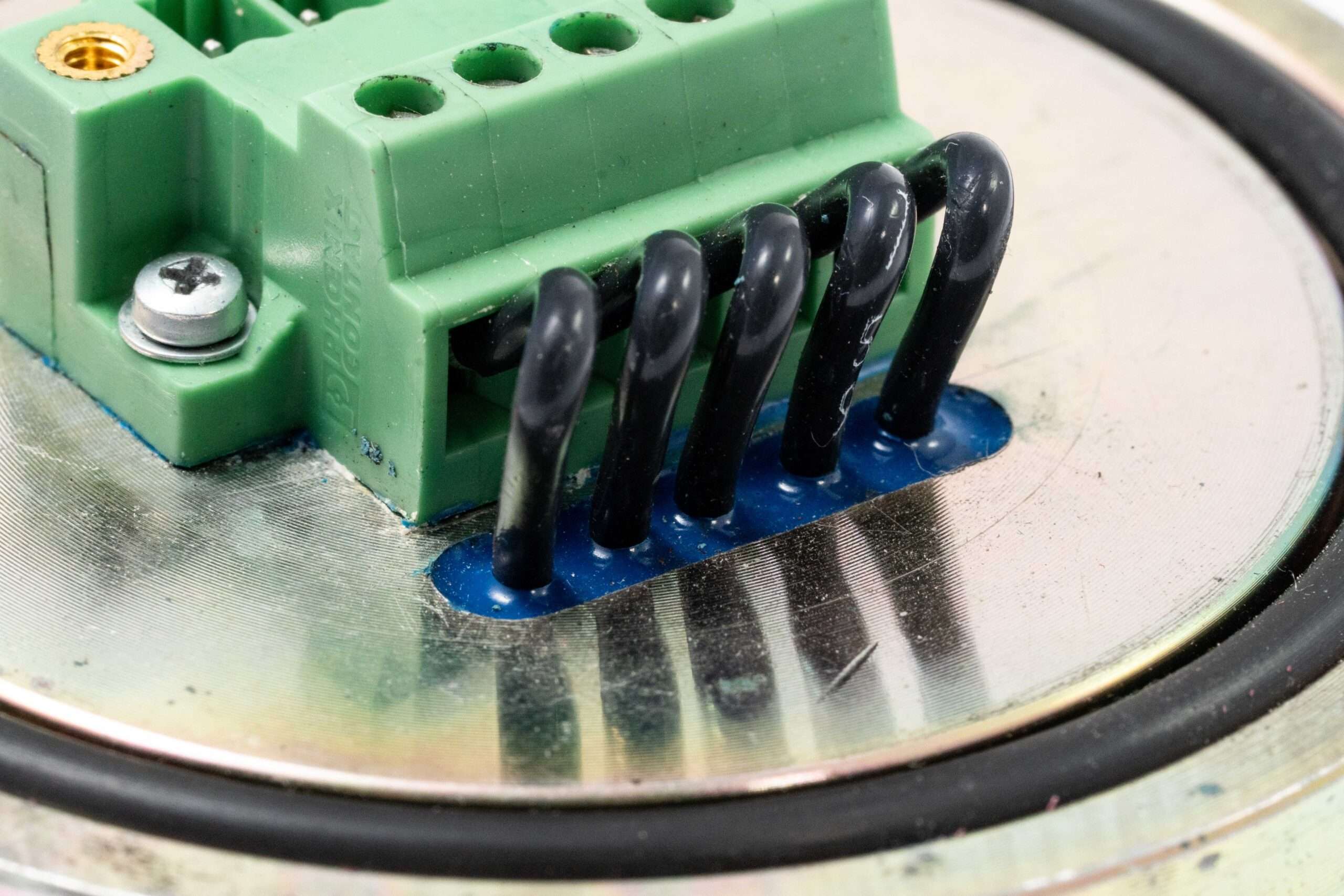

- Penetration into the Process: As said before, sensors are directly installed on equipment to analyze their performance. Although hermetic sealing creates an airtight seal, it allows sensors and feedthroughs to comes into direct contact with the process media, such as liquids or gases, being monitored. This direct integration enables accurate real-time monitoring of conditions. For instance, in oil condition monitoring, hermetically sealed sensors can still contact the oil to measure parameters like temperature, viscosity, and contamination levels without getting damaged. Hermetic sealing helps protect these connections, enabling precise and uninterrupted data collection.

- Environmental Protection Against Harsh Conditions: Although sensors have made remote monitoring easy in challenging work environments, they are subjected to extreme conditions, such as heat, cold, humidity, icing, or submersion, etc. These harsh conditions may affect their working condition, leading to unreliable data, failure, and potentially costly downtime. Hermetic seals protect sensors and electronic components from environmental elements, safeguarding the integrity of connections and ensuring their consistent performance. By preventing corrosion, moisture ingress, and other forms of environmental damage, hermetic sealing enhances the overall reliability and lifespan of monitoring equipment.

- Hazardous Location Certifications: In many industries such as oil and gas, chemical processing, and mining,

CBM equipment is operated in hazardous locations. So, they must comply with stringent safety standards and certifications, such as ATEX (Atmosphères Explosibles), UL (Underwriters Laboratories), and IECEx (International Electrotechnical Commission Explosive). Hermetic sealing offers the necessary protection to meet these certifications. Hermetically sealed connections prevent the ingress of explosive gases and dust, ensuring that monitoring equipment safely operates without risking ignition or failure in hazardous areas.

- Suited for Wired and Wireless Condition Monitoring Systems: Wireless condition monitoring systems are gaining traction. However, the demand for wired CBM continues to be high in many applications. Each type has its own advantages and hermetic sealing can help improve the performance of both systems.

- Wired CBM: Wired connections ensure secure signal transmission in any work environment. This feature can be crucial in applications where reliability and signal integrity are essential. Hermetic seals help protect cables and connections from environmental damage, ensuring a stable and secure data transmission. Hermetic sealing helps maintain the integrity of wired connections by preventing corrosion, signal loss, and other issues.

- Wireless CBM: Wireless condition-based monitoring ensures ease of deployment in hazardous and hard-to-reach locations. Although wireless CBM systems may have fewer components, hermetic sealing can be done at antenna, sensor, and gateway level. They help protect these components from environmental stressors while ensuring reliable data transmission and reducing the risk of signal interference.

Whether for wireless or wired monitoring, hermetic sealing ensures accurate, safe, and reliable data transmission, supporting the goals of predictive maintenance and operational efficiency. As industries continue to embrace IIoT for condition-based monitoring and predictive maintenance, the demand for hermetic sealing solutions will grow. If you are considering hermetic sealing for a condition-based monitoring system, be sure to partner with an experienced hermetic sealing services provider like Douglas Electrical Components. We can create interconnect solutions with custom hermetic seals and feedthroughs to meet the demands of challenging work environments. Contact us today to learn more about our expertise in creating hermetic solutions for condition-based monitoring systems.