Aerospace testing equipment, operating in the challenging conditions of high altitudes, severe weather, varying atmospheric pressures, and rapid temperature changes, tests the reliability and integrity of electronic and electrical connections. This is where aircraft cables and connectors come into play. They are instrumental in maintaining the functionality and integrity of the aircraft’s electrical systems. However, it’s crucial to understand that not all aviation connectors and cables are equal. Some applications demand the highest standards of safety and reliability. This is where hermetically sealed aviation connectors and cables excel. They are known for their unmatched reliability and superior performance. With this knowledge, you might have a few questions regarding some popular aviation cable connectors used today. Do you want to know how hermetic sealing enhances the reliability of aviation connectors and cables? This post answers these questions and more.

Types of Aerospace Connectors and Aircraft Electrical Connectors

The aerospace industry utilizes mission-critical electronic and electrical systems, such as engine and flight control systems, navigation, and communication systems, to ensure safe operation. These systems demand a consistent supply of electricity, which is ensured through a network of aircraft electrical connectors and cables. Various types of aircraft electrical connectors are designed for specific purposes. For instance, those designed for military aircraft must meet military specifications or Mil-spec requirements. Below are a few popular types of aircraft electrical connector types used in military aircraft electrical systems.

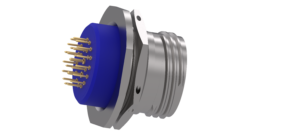

- MIL-DTL-38999:

Hermetically sealed 38999 connectors

These circular military aircraft electrical connectors are distinguished by their quick disconnect, high-density with bayonet coupling features. MIL-DTL-38999 connectors can be operated across a wide temperature range of -65°C-+175°C.

- MIL-DTL-5015: These circular military connectors are designed to handle heavy current loads and can be operated across a wide temperature range from -55°C to 200°C.

- MIL-DTL-26482: These circular aircraft wire connectors enable quick connection and disconnection and are suited for many military aircraft applications.

- MIL-DTL-24308: These rectangular Mil-spec connectors feature solid machined contacts and belong to D-subminiature family. MIL-DTL-24308 connectors can be operated continuously in temperatures from -55 °C to +125°C.

- MIL-DTL-83513: MIL-DTL-83513 rectangular Mil-spec aircraft electrical connectors are smaller than D-subminiature connectors and can be operated in temperature ranges from -55 °C to +125°C.

- MIL-DTL-32139: These rectangular Mil-spec aircraft electrical connectors feature nano-prewired connectors in single and double rows and can be operated in temperature ranges from -55 °C to +125°C.

In addition to the above, below are a few generic aircraft electrical connectors used for the purpose.

- RF connectors: As the name suggests, these connectors deal with RF communications. They are generally used to connect the antennas to the aircraft communication systems.

-

- SMA (Sub Miniature A): These are the smallest connectors designed for small cables operating in frequencies at 0 GHz and 11 GHz.

- N: These large threaded connectors are designed for cables with 0.25 inches outer diameter or more. N-type connectors are designed for frequencies between DC (0 Hz) and 11 GHz. They are used in applications where mechanical robustness and excellent RF performance is needed.

- TNC: These midsized coupling connectors are used on most traffic collision avoidance system (TCAS) antennas. They can be operated in the frequency range of DC and 11 GHz.

- Triaxial Coaxial Connectors: These connectors feature three conductors and assure better interference rejection and higher bandwidth than traditional coaxial connectors. They are used in many high-frequency aerospace applications.

- Thermocouple Type Connectors: These connectors transmit voltage values and temperature readings from a thermocouple to a host computer or meter.

- Type J: These connectors feature a negative leg of Constantan (copper-nickel) and a positive leg of iron wire. They are thermocouple-type connectors with a temperature range from -40°C to 750°C. They are particularly used for aerospace applications that require high temperatures.

- Type K: These thermocouple connectors operate from -270 °C to 1260°C. They feature Alumel and Chromel wires and have an output of -6.4 to 9 mV over a wide range.

- Type E: These aircraft connectors have Nickel-Chromium/Constantan wires and are suited for temperature range from -270°C to 870°C.

- Type T: These connectors can be operated across a temperature range from -200°C to 200°C. They are suited for extreme low-temperature applications, such as ultra-low freezers and cryogenics.

- USB: These aircraft connectors are designed for lightweight and low-loss cables. Many connectors are compatible with USB 2.0 and USB 3.0 specifications. Some applications may need them to adhere to MIL-DTL-38999 specifications.

- RJ-45: These electrical connectors are used in data and power transmission systems and cables with Cat6 and 6a data speeds.

Benefits of Hermetic Sealing in Aviation Connectors and Cables

Hermetic sealing creates an airtight seal around aviation wire connectors and cables designed for use in various aircraft systems. This sealing process helps enhance the reliability and safety of the cables and connectors in many ways.

- Protection from Environmental Factors: Hermetic sealing prohibits solids, liquids, and gases from damaging the sensitive electronic components in several mission-critical aircraft equipment such as landing gear, engines, tail rudders, wing flaps, and instrumental panels. They also protect these components against contamination, humidity, vibrations, and high pressures.

- Improved Longevity and Durability: Hermetic sealing is created using ceramic-to-metal, glass-to-metal, or silicone-based polymer sealing that protects cables and connectors from physical damage and corrosion. This hermetic sealing helps minimize maintenance requirements and extend the lifespan of connectors.

- Safeguards Against Aggressive Media: Hermetic aircraft electrical connectors safeguard against aggressive media in hazardous environments (ATEX).

- Stable Pressure Differentials: Hermetic seals possess strict leak rates, which prevent seal penetration and improve their ability to withstand high pressures and maintain stable pressure differentials.

- Customizable: Hermetic seals can be customized to cater to high power/voltage insulation, increased heat dissipation, and high frequency/RF optical data transmission requirements.

- Compliance with Safety Standards: Hermetically sealed connectors and cables exceed the stringent performance and safety standards set by aviation regulatory bodies. This compliance ensures their suitability and reliability in the demanding aviation environment.

Douglas Electrical Components: Experts in Hermetic Solutions for Aviation Connectors

At Douglas Electrical Components, we design and manufacture hermetic solutions for military and aerospace applications. Our epoxy sealing technology helps create a water-proof and hermetic sealing capable of protecting electronics from water, vapor, gases, and liquids. Designed and proudly made in the USA, we can design and manufacture hermetic solutions complying with International Traffic in Arms Regulations (ITAR) and Defense Federal Acquisition Regulation Supplement (DFARS) regulations. In addition to technology, our experts employ various connectors and materials to create lightweight yet high-density hermetic solutions. Over the years, we have created airtight hermetic sealing solutions for aircraft electrical connectors and cables for antennas, military medical devices, satellite communications, sensors, and monitoring devices. Contact us today to learn more about our expertise in creating hermetic solutions for aviation cable connectors.