As aerospace and military technologies evolve, the demand for reliable and durable cables that support high-speed data transmission in challenging environments is rising. This is where M27500 & M22759 cables can make a difference. This post explores the significance of M27500 and M22759 cables and their indispensability in the military and aerospace industries.

Overview of M27500 and M22759 Cables

M27500 Cables

M27500 | NEMA WC 27500 | Mil DTL 27500 is a range of specialized cables developed for demanding military and aerospace applications. These high-performance cables feature single or multi-conductors with single or double shields and jackets. They can perform well in temperatures between 150 and 260 Celsius. MIL DTL 27500 cables feature a 16-character part number that specifies the number of insulations, conductors, shields, and jackets.

M22759 Cables

MILDTL- M22759 | SAE AS22759 is a range of high-performance and high-temperature cables with extruded ETFE or PTFE or Polyimide tape insulators, and stranded conductors. These cables feature high-strength conductors and abrasion-resistant insulation, ensuring maximum performance under mechanical stress. Construction of M22759 Spec wires make them ideal for applications where overload stability, smoke emission, and flammability are concerns.

What are the differences between Mil-Spec M22759 and Mil-Spec M27500 Cables?

Although both M27500 and M22759 are developed for military and aerospace applications, they are rated for different operational voltage and temperature ranges and use different insulations. For instance, Mil-Spec M22759 wires use cross-linked ETFE insulation, whereas M27500 wires use FEP, PTFE, and ETFE insulation. The Mil-Spec M27500 wire has a wider temperature and voltage range than the Mil-Spec 22759.

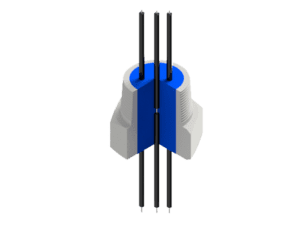

Importance of Hermetic Feedthroughs in Military Cables

Hermetic feedthroughs help ensure the integrity of the systems where airtight sealing is necessary. They help augment the performance of these cables in the long run. How? The following pointers will help you understand it better.

Hermetic feedthroughs help ensure the integrity of the systems where airtight sealing is necessary. They help augment the performance of these cables in the long run. How? The following pointers will help you understand it better.

- Hermetic feedthroughs are enclosures that prevent hazardous liquids and gases from migrating across the bulkhead.

- Hermetic sealing protects the cables from environmental factors, such as humidity, which helps maintain their consistent electrical performance in critical applications across military and aerospace industries. Douglas seals directly to the conductor, preventing any penetration of air or liquids between the conductor and its jacketed material as well as between the strands themselves. This is added protection beyond any grommet, gland, or compression seal.

- Sealed cables create a high-density option with plug-and-play operation. Integrate labeling, shielding, and interconnect solutions to design for manufacturing and the field.

- These feedthroughs create a barrier against the ingress of gases, moisture, and small particulate matter. This is critical in aerospace and military environments where continuous exposure to such elements can lead to short circuits, corrosion, and other forms of degradation affecting the cable performance.

- The feedthroughs also limit the leakage from the side of vacuum pressure to atmospheric pressure.

- Hermetic sealing helps M27500 and M22759 MIL Spec cables perform well in controlled environments, such as vacuum systems or pressurized containers. They help maintain the integrity of the system by ensuring the external atmospheric conditions do not affect the internal conditions, such as in military and aerospace applications where precise environmental conditions are necessary for the operation of sensitive components.

- Although the initial costs of hermetically sealed cables may be the same, their lasting performance, and reduced maintenance requirements would offset the costs.

Douglas Electricals: Your Trusted Source for Hermetic Feedthroughs

Hermetically seal your electrical feedthrough while customizing it to your exact needs.

Hermetically sealed M27500 and M22759 cables create an impenetrable barrier against environmental factors, ensuring the protection of the internal conductors. Douglas Electrical is an ITAR registered business for military applications and can provide AS9102 First Article Inspection on request. We provide custom and made-to-order semi-custom feedthroughs, which are engineered to deliver exceptional sealing performance and help ensure a durable and reliable connection. We can also provide value-added assemblies incorporating cable armor, sealed connectors, sleeving, sensors, circuits, and terminations. Our technical application and sales engineers will work with you to offer you the right solution for the end product. Design and assembly are performed by our IPC-620 certified technicians. Contact us today to discuss your requirements.