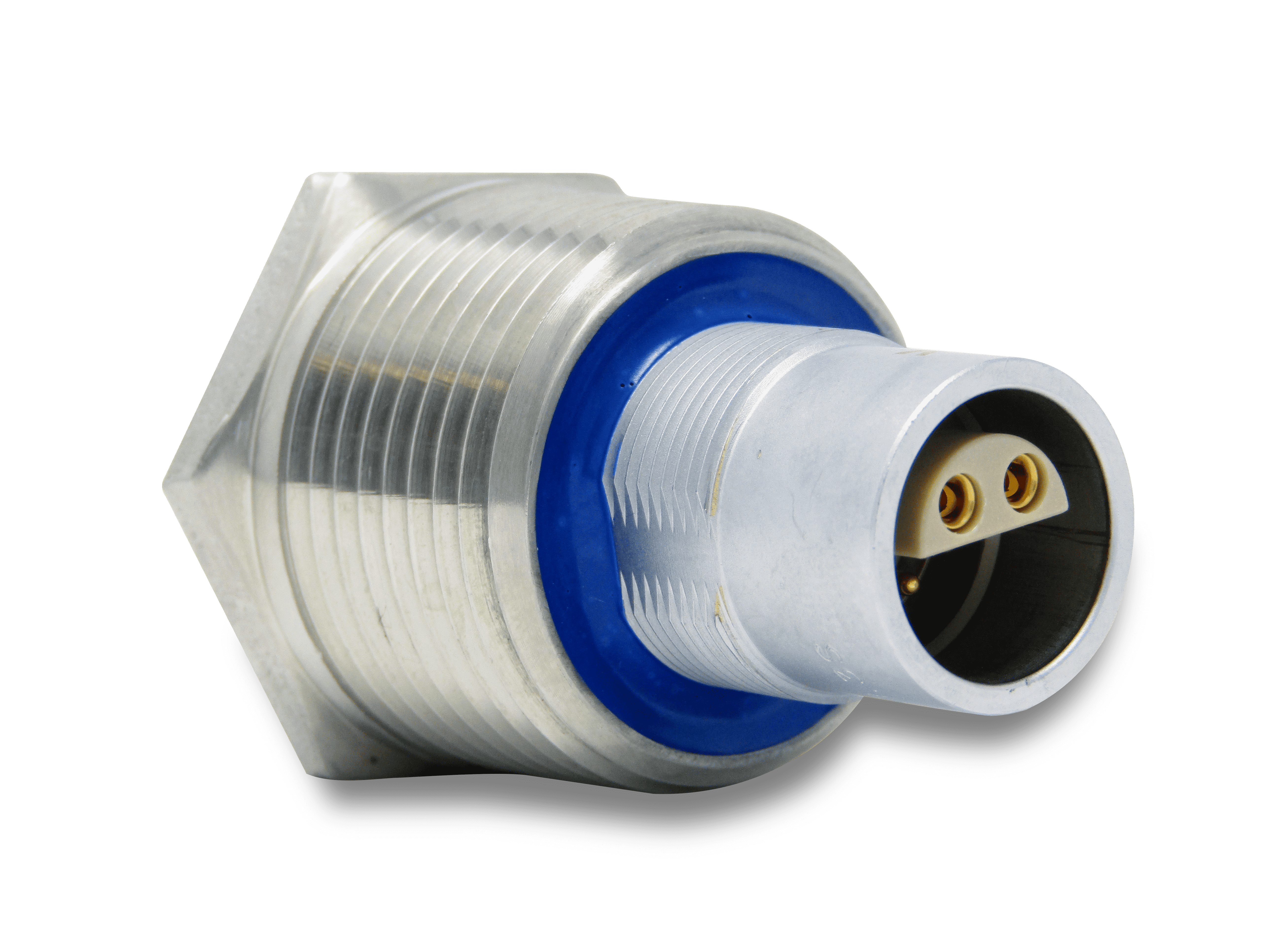

Hermetic push-pull connectors are specialized electrical connectors designed to create a high-quality, hermetic seal in vacuum and high-pressure environments with the convenience of simplified connector engagement.

Hermetic push-pull connectors

Douglas Electrical takes standard, non-hermetic commercially available push-pull connectors and converts them into hermetic connector assemblies. We integrate a variety of connections including wires, cables, pins, flex circuits, and more.

Hermetic push-pull connectors are simple to use. These connectors can be quickly connected and disconnected, even in challenging environments such as high-vacuum or high-pressure conditions. This makes them suitable for use in applications where frequent connection and disconnection is required, such as in testing or maintenance procedures, including test and measurement applications or on equipment requiring routine maintenance or inspection.

Push-pull connectors are highly durable and resistant to damage. They are typically constructed from high-quality materials such as stainless steel or titanium, which makes them resistant to corrosion and other forms of wear and tear.

Types of Push-Pull Connectors

There are various types of push-pull connectors available to meet different application needs:

- Circular push-pull connectors: These connectors are perfect, for applications that need durable connections. They are commonly used in devices, industrial machinery and communication systems where reliability’s crucial.

- Push-pull cable connectors: Ideal for creating a hermetic seal with cables these connectors ensure your connections stay safe and intact even in challenging conditions. They are used in aerospace, defense, and telecommunications applications.

- Push-pull electrical connectors: Designed to provide secure electrical connections in tough environments these connectors can withstand extreme temperatures, vibrations and mechanical stress. They are suitable for military, aerospace and industrial use.

- Push-pull feedthrough and push-pull vacuum feedthrough: These connectors are essential for enabling passage through barriers while maintaining a hermetic seal. They maintain the integrity of the barrier while enabling fluid connections in vacuum chambers clean rooms and high-pressure environments.

- Sealed push-pull connectors: Used to create sealed connections for added protection against dust, moisture or other contaminants. These connectors are commonly used in equipment, marine environments and medical devices.

- MIL-DTL-81703 connectors: These military grade connectors are engineered for reliability in aerospace and defense applications. MIL-C 81703 connectors are Known for their durability and resistance to factors they perform well in extreme conditions critical, to mission critical systems.

- MIL-DTL-38999 connectors: Circular connectors, with top notch performance are widely used in military and aerospace applications due to their environmental sealing and durability. MIL-DTL-38999 connectors are favored for their capability to withstand vibrations and challenging environmental conditions.

The Douglas Advantage for Push-Pull Connectors

Douglas Electrical Components can convert virtually any standard push-pull connector into a hermetic connector assembly. This can include the existing mechanical interface or use a custom machined housing in a variety of sealing methods and materials. Push-pull connectors can be designed into a sealed bulkhead assembly or simply be used as a backpotted connector with hermetic properties and integral wires, pins, or cables. We utilize various trusted push-pull connector brands and series to maintain your backwards compatibility and ease of integration.

Looking to design a solution? Reach out to our team with your requirements, and we’ll get started on creating the perfect hermetic push-pull connector assembly for your needs.