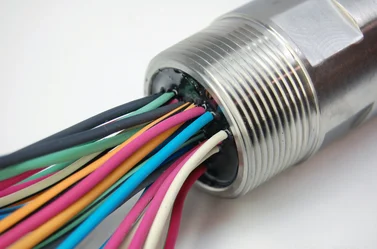

With medium-voltage switchgear, progress is being made with regard to finding alternatives to SF as an insulation gas. Designs that incorporate dry air or a mixture of fluoroketone, nitrogen and oxygen as the insulating gas are being explored to minimize environmental impact. Oil, vacuum and CO are other alternatives to SF. Regardless of the type of insulation, it is important that all individual components used within the switchgear assembly can withstand harsh environments, temperature extremes and regular submersion in water. Among these components are the hermetic feedthroughs that carry conductor wires in and out of the gas-insulated cavity. A switchgear feedthrough can take on different design possibilities to ensure the power and signal is safely transferred.

Already a dominant choice for switchgear applications, epoxy-based hermetic feedthroughs are poised to become even more popular as a variety of SF6 alternatives come into play.

In this application note, learn about:

- Epoxy-based sealing technology and its chemical compatibility

- What leak rates mean in regards to hermetic feedthroughs

- Optional designs including integral connectors, wire bushings, and inline connectors

Read our latest application note for more detailed look at how various switchgear insulation gases affect feedthrough performance.

Find more information on switchgear feedthroughs

Learn more about our specific capabilities in the electrical power distribution and power generation market.