About Douglas Electrical Components

Hermetic Solutions for Your Sealing Challenges

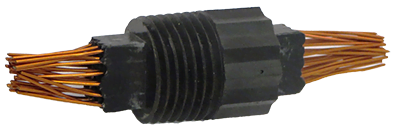

For over 75 years, Douglas Electrical Components has provided fiber optic, signal and power interconnect solutions designed to meet the challenging demands of gloveboxes, medical equipment, semiconductor manufacturing, space simulation, military, vacuum systems, electrical distribution, hazardous locations and more. From sealed connectors and hermetic wires feedthroughs to pin headers and electronics encapsulation, we look forward to new opportunities where we can push our boundaries even further to meet your unique application needs.

Douglas Electrical can help you reduce your total installed cost for point-to-point sealed electrical solutions while saving you time. Choose the exact connector, cable, wire or fiber you need and partner with Douglas Electrical Components to hermetically seal it within the bulkhead or fitting you require. Our products are designed to provide an optimal balance of performance and price, while exceeding expectations for delivery, quality, and reliability.

Through the acquisition of Electronic Products, Douglas offers a complete line of microelectronic hermetic packages to compliment our hermetic sealing capabilities. These HTCC and glass-to-metal seals are used in RF/microwave packages, power discrete packages, TO-headers, and optoelectronic packages for a variety of industries and applications. Choose standard configurations or design to spec with the EPI engineering team.

Operational Advantages

- Work with a partner that understands hermetics, customization, and critical quality

- LEAN manufacturing business model

- In-house rapid prototyping and design qualification

- Expedites down to 1 week lead times, even for custom designed products, are typically available

- Just in Time (JIT) purchase order management with strong supply chain and business partners

- Designed and manufactured in the USA

- Tooling designed and built in-house

US Manufacturer

founded in 1944

ISO 9001/14001

Certified

Designer & manufacturer

of custom solutions

In 1975, Douglas pioneered the development and practical application of electrical wire feedthroughs using epoxy technology, which had been utilized in manufacturing field coils for magnetic flow meters.

Driving Hermetic Feedthrough Technology

In 1944, the company was founded as Douglas Engineering Company in Newark, NJ by Edward B. Douglas. In addition to working as a consulting engineer, initial manufactured products were electro-mechanical assemblies used in propeller driven aircraft. Douglas Electrical Components developed the industry’s first epoxy-based wire feedthroughs in 1975. Since then, we have continuously improved our epoxy-based sealing technologies. And today, our hermetically sealed feedthroughs and connectors thrive in the most demanding application environments—from oil fields to battlefields to outer space.

- Extremely reliable and robust hermetically sealed solutions for applications where physical space is limited (increased signal density, eliminated connections)

- Lower cost “end-to-end” solutions with Design for Manufacturing (DFM) focus

- Improved design flexibility on new systems – plan on saving space and improving reliability

- Specify exactly what you need rather than having to compromise on your solutions

Design Capabilities

- Vacuum to 1×10-9 Torr

- Pressures as high as 15,000 psi

- Temperatures from -200°F to +350ºF

- Wire gauges from 38 AWG to 500 MCM

- Conductor counts from single wire to 3,200 in a single feedthrough

- Cable lengths from stubs to 2,000 meters

- Chemical/Fuel/Gas/Radiation compatibility is proven

Operations

- ISO 9001:2015 | ISO 14001:2015

- ITAR-DDTC Registered

- AS9102 First Article Inspections available upon request; contact factory.

- IPC/WHMA-A-620 Certified Trainers and Application Specialists

- UL 984 | UL 1203 | UL 674 Certified Products

- LEAN Manufacturing

- Hermetically and electrically tested assemblies

Technology Categories

- Hermetically sealed connectors

- Wire and cable feedthroughs

- Power feedthroughs

- Value-added assemblies and harnesses

- Fiber optic assemblies

- Encapsulated circuits

- Glass-to-metal seals

- HTCC ceramic seals

Designing with Douglas' Hermetic Epoxy

- Reduce number of connections by providing complete end-to-end connectivity

- Dramatically increase density of conductors passing thru a bulkhead

- Specify exactly the connector/wire/cable you require

- High conductor count cables including:

- Twisted shielded pairs, coaxial wire, fixed impedance, flex circuits and other

- All insulations types including:

- FEP, PTFE, PVC, PE, XLPE, TPR, Neoprene and others

- Standard and custom bulkhead mounting options

- Seal virtually any connector including:

- Military specs, plastics, plated metals and custom designs

- Fully connectorized harness and basic wire feedthrough solutions

- Seal rigid circuits, flex circuits, hybrid circuits, and FFC cable with active and passive components

- Extremely robust – resistant to physical and thermal impact with reliable use 30+ years

- Virtually any housing/fitting material can be used including:

- Molded plastics/polymers, common metals (brass, copper, aluminum & stainless steel), exotic metals (titanium, AlBeMet) and customer furnished housings

- Ability to utilize customer furnished connectors, housings, cables, and sub-assemblies

Ready to connect?

Are you ready to start designing? We’re here to help. Share as much detail on how we can assist you and our technical sales engineers will follow up to partner on any new or existing design.